You can build a strong brand by choosing the right private label process for dog collars for large dogs. Select suppliers who offer customization and ensure strict quality control. Match your product design with your brand identity and what customers need. Pay attention to compliance and durability so your collars stand out. The market keeps growing:

The global dog collar market reached USD 4,350 million in 2024.

It is expected to hit USD 4,650 million in 2025.

By 2030, the market may reach USD 6,750 million with a CAGR of 7.2%.

Explore more daily commute dog collar options to find the best fit for your brand.

Key Takeaways

Pick suppliers you can trust. They should let you change designs and check quality.

Learn about your buyers. Make collars that fit what they want and need.

Add safety parts like shiny strips and tough clips. This helps dogs stay safe and comfy.

Put your logo and cool boxes on your collars. This helps people remember your brand.

Let real dog owners try your collars. Ask them what they think. Use their ideas to make your collars better.

Follow all safety rules. Get the right certificates. This helps customers trust you.

Plan how you will make your collars. Think about how many you need and how long it takes.

Ask buyers for their thoughts after you start selling. Find problems and make your collars even better.

Private Label Opportunities for Dog Collars for Large Dogs

Market Demand for Large-Dog Collars

Many people want dog collars for large dogs. Younger buyers, like millennials and Gen Z, want cool collars with tech features. Older buyers, ages 50-59, often buy fancy collars because they have more money. People care about pet safety and health, so the market keeps growing. The 50-59 age group is 22% of the market. The 40-49 group is 19%. Younger buyers, ages 30-39 and under 29, make up over a third of buyers. Many customers want eco-friendly materials and smart technology in their collars.

If you want to help these buyers, look at daily commute and travel dog collars for large dogs. These collars are good for people who want style and function.

Branding and Customization Benefits

Private label brands can be special by offering custom choices. You can pick your own logo, like metal, rubber, or printed ones. Many suppliers let you choose colors and patterns or make your own. Custom boxes or hang tags make your product look nice and easy to remember. Some companies, like Wedogy, PrideBites, and Szoneier Leather, let you order small amounts. This helps you try new ideas without spending too much.

Here is how private label brands stand out:

Customization Options | Branding Strategies |

|---|---|

Debossed or embroidered logos | Good branding makes your product seem better |

Custom color combinations | Strong branding makes customers come back |

Personalized name tags or QR code integration | Collars show off your brand |

Custom packaging with branded boxes or hang tags | Fits big dogs and looks great |

You also get these good things:

Benefit Type | Description |

|---|---|

Custom Logo Embroidery | Shows off your brand |

Unique Design Patterns | Attracts your best customers |

Branded Packaging Solutions | Makes people remember your brand |

Customization Options | Lets you pick logos, colors, and patterns |

Brand Positioning | Helps your brand get noticed |

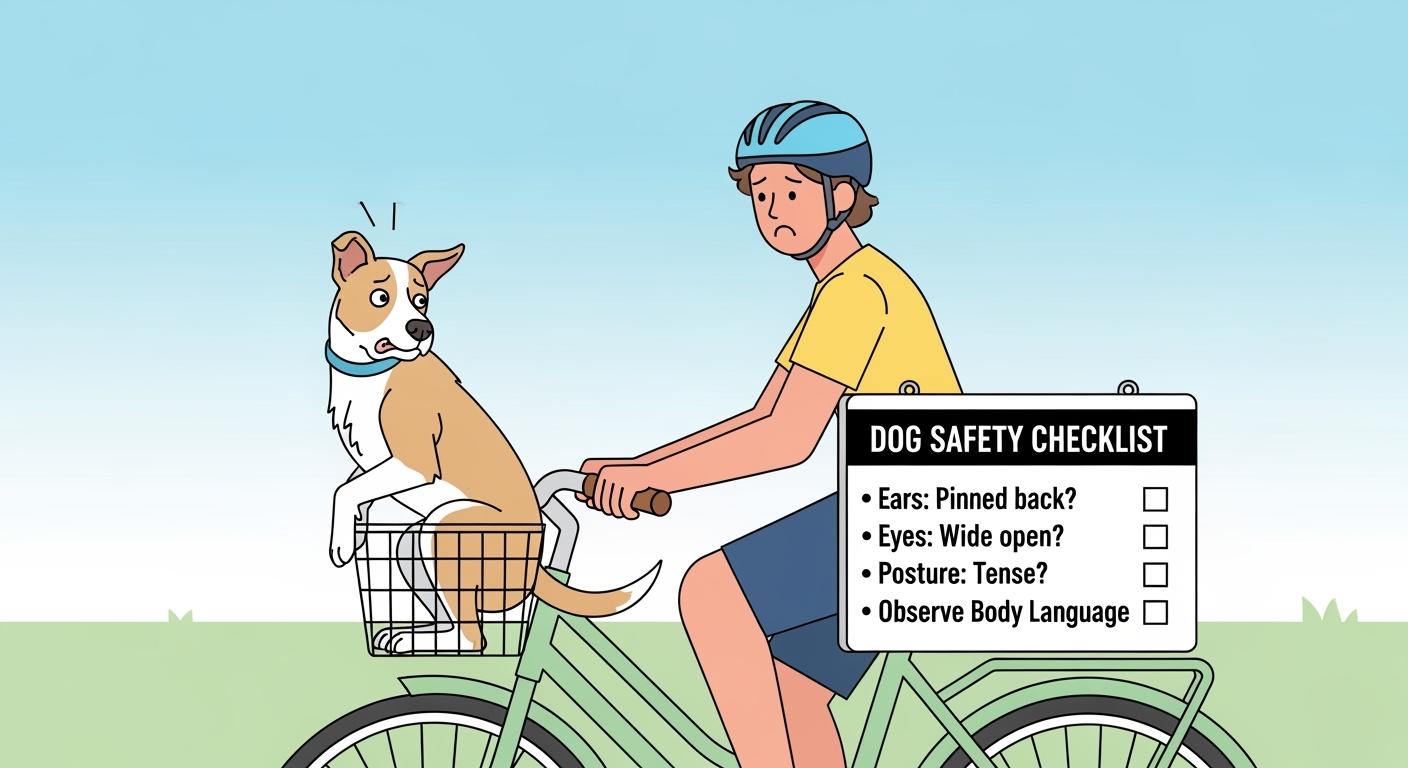

Risks of Poor Design for Large Breeds

If you forget what big dogs need, your brand can get hurt. Bad design can make dogs uncomfortable or unsafe. If customers have a bad time, they might write bad reviews. That can hurt your business. Collars need things like reflective parts and strong fabrics for safety. If you focus on quality, people will trust your brand and buy again.

Tip: Always test your dog collars for large dogs with real users. Get their feedback before you make a lot of collars. This helps you avoid mistakes and keeps your brand strong.

Defining Your Large-Dog Collar Line

Target Markets and Positioning

You need to know your target market before you design your product line. The pet industry keeps growing because more owners want premium and custom accessories. Many buyers look for products that match their dog’s needs and their own style. You can focus on niche markets to make your collars stand out. For example, some buyers want eco-friendly materials, while others want smart features or extra safety.

Here are some strategies to help you define your product line:

Focus on niche markets to set your collars apart.

Make sure your collars have high quality.

Learn about your customers so you can market to them better.

When you position your collars, think about these important factors:

Factor | Description |

|---|---|

Scalability | Can your collars meet higher demand or add new features? |

Compliance | Do your collars meet safety and quality rules in your area? |

Innovation | Are you adding new features for safety, durability, or smart tech? |

Long-term ROI | Will your collars last and save money over time? |

If you want to see more options for daily use, check out daily commute and travel dog collars.

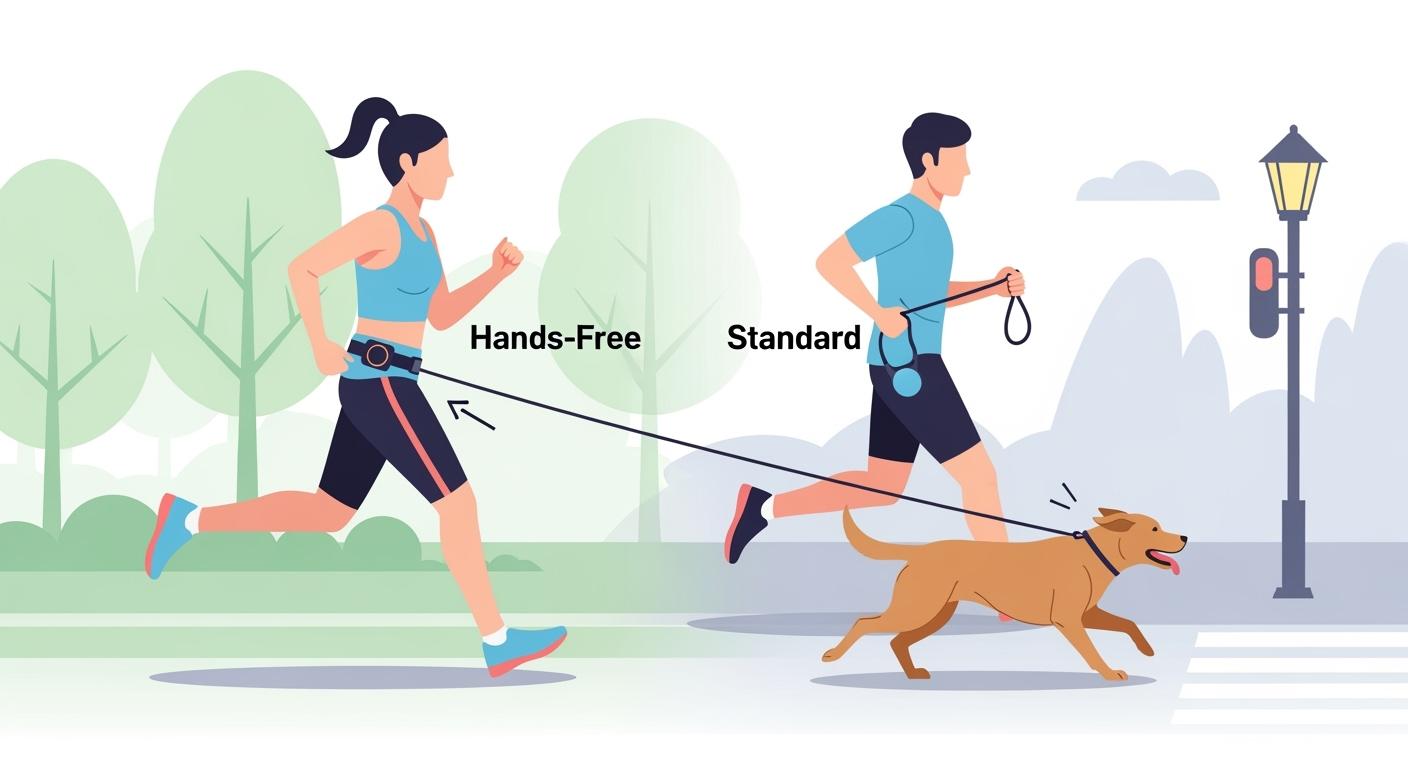

Key Specs: Size, Strength, Comfort

Large dogs need collars that fit well and keep them safe. You should look at the size, strength, and comfort of every collar you offer. Most large breeds weigh between 50 and 90 pounds and stand over 22 inches tall. Giant breeds can weigh over 100 pounds and reach up to 36 inches in height.

Breed Type | Weight Range (lbs) | Height Range (inches) |

|---|---|---|

Large Breeds | 50–90 | 22+ |

Giant Breeds | 100+ | 22–36 |

Owners of large dogs want collars that are strong and comfortable. Many large breeds need joint support, regular training, and enough exercise. You should use sturdy materials and soft padding to keep dogs safe and happy. Always test your collars for strength and comfort before you sell them.

If you want a collar with extra safety, you can look at the reflective dog collar.

Branding Elements: Logo, Colors, Packaging

Branding helps your collars get noticed. You should use a strong logo and clear colors to make your brand easy to remember. Good packaging also makes your product look better and keeps it safe during shipping.

Here are some branding tips:

Show value by focusing on safety, durability, and style.

Tell your brand story so pet owners feel connected to your products.

Use a logo and design that people will remember.

Tip: Authentic branding builds trust. When you share your story and values, customers feel closer to your brand.

You can learn more about branding and product ideas by visiting the StridePaw blog.

Technical Requirements for Dog Collars for Large Dogs

You should pick the best material for your collars. Every material has good points. Some are better for active dogs. Others feel softer on the skin. Here is a table to help you compare the most common materials:

Material | Advantages |

|---|---|

Leather | Durable, comfortable, becomes soft over time, gentle on skin and fur |

Nylon | Cheap, light, pretty strong |

Biothane | Strong, waterproof, good grip, great for outdoor training |

Leather collars last a long time and feel soft. Nylon collars are cheaper and lighter. Biothane collars are great for dogs that play outside. They do not get ruined by water or dirt. You can also find collars made from neoprene or coated nylon. These materials are tough and keep their shape. If you want extra safety, try a reflective dog collar. This type helps dogs stay seen at night or in dark places.

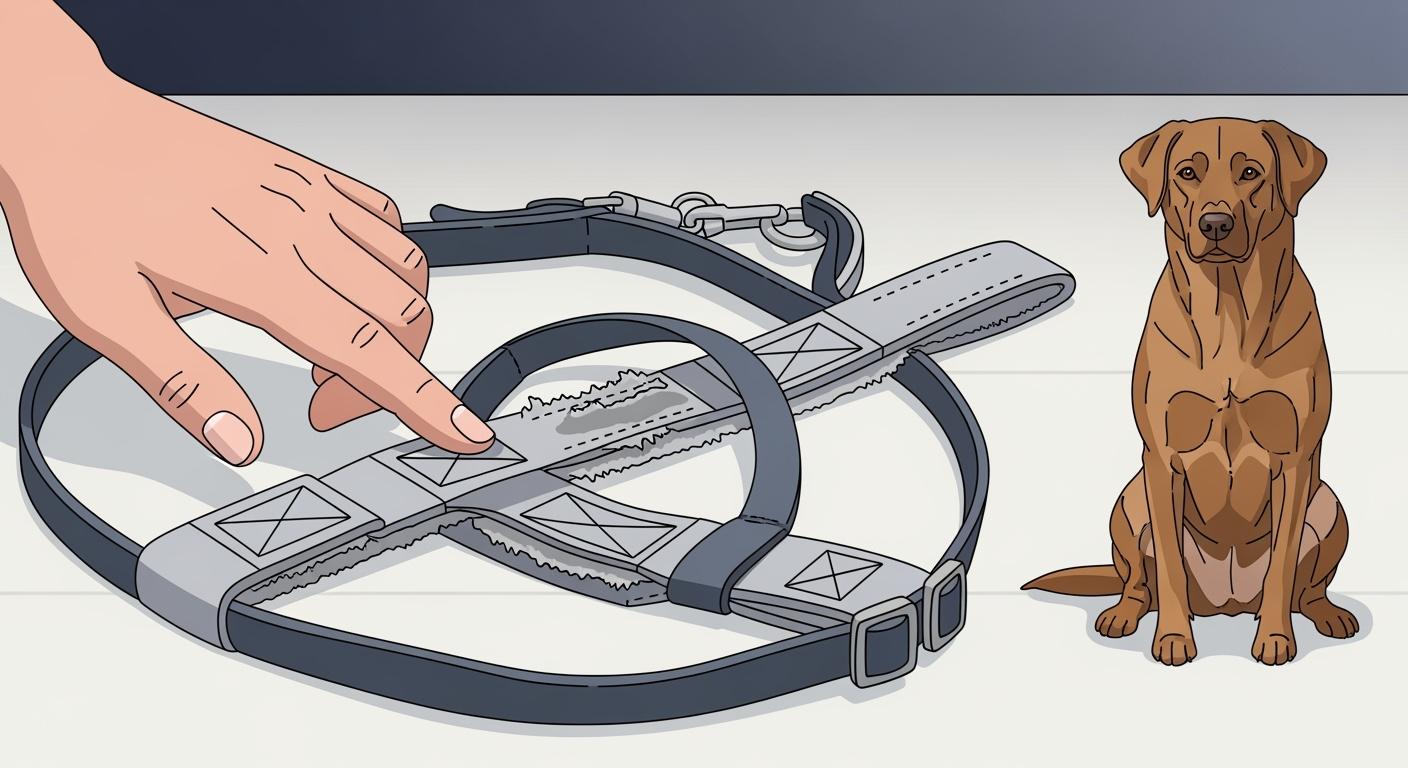

Hardware: Buckles, D-Rings, Adjusters

The hardware on your collar needs to be strong and safe. Buckles, D-rings, and adjusters hold the collar together. They keep your dog safe. You should choose hardware that does not rust or break. Here is a table to show you the best choices:

Material | Durability | Rust Resistance | Weight | Cost | Typical Use Case |

|---|---|---|---|---|---|

Brass | Very strong; gets stronger with age | Great rust resistance | Medium weight | Medium to high | Fancy collars for active dogs |

Stainless Steel | Super strong | Great rust resistance | Heavier than brass | High | Work collars, strong pull dogs |

Zinc Alloy | Pretty strong | Okay (can rust) | Light | Low to medium | Fashion collars, casual use |

Plastic/Polymer | Not very strong | Does not rust but can break | Very light | Low | Puppies, short-term use |

Stainless steel and brass are best for big dogs. These metals do not rust and can handle strong pulling. Zinc alloy and plastic cost less but do not last as long. For safety, use strong S-hooks for ID tags. This keeps tags from falling off when dogs play.

Strength and Safety Testing

You want your dog collars for large dogs to be strong and safe. Makers test collars before selling them. They check for strength, toughness, and safety. Here are some important steps:

Use tough materials like BioThane, neoprene, or coated nylon for hard use.

Make sure collars have many holes so you can change the size as your dog grows.

Pick rust-proof hardware like stainless steel or brass for buckles and D-rings.

Choose quick-release buckles to stop choking or accidents when dogs play.

Attach ID tags with strong S-hooks to keep them safe.

Makers use tensile testing to see how much force a collar can take before it breaks.

Regular tests copy real-life situations to make sure collars work under stress.

Tip: Always ask your supplier about their testing process. Good testing means safer collars for big dogs.

If you want a collar that meets high safety standards, try a reflective dog collar. This type helps your dog stay seen and safe during walks.

Comfort Features for Large Breeds

When picking dog collars for large dogs, comfort is very important. Big dogs have strong necks and sometimes sensitive skin. The right comfort features help your dog feel happy on walks or during training.

A lot of owners want padded collars. Padding gives extra softness for dogs that pull or move a lot. Soft padding helps protect the neck and stops rubbing. Some collars use neoprene or foam lining. These materials feel gentle and help stop skin irritation.

Water-resistant collars are also helpful. If your dog likes to play outside, rain or mud will not ruin the collar. Water-resistant collars keep your dog dry and comfy. They last longer because they do not soak up water or bad smells.

Eco-friendly materials are popular too. You may care about the planet and your dog’s safety. Collars made from recycled nylon or plant fibers are safe and good for the earth. These materials feel soft and do not have harsh chemicals.

Adjustable collars help you get the right fit. Big dogs can grow fast, and their neck size can change. Collars with easy adjusters let you change the size when needed. This keeps the collar snug but not too tight. A good fit stops slipping and makes walks safer.

Here are some comfort features that owners like best:

Padded collars for extra comfort and protection

Water-resistant materials for outdoor adventures

Eco-friendly choices for safety and the planet

Adjustable sizing for the best fit

Wide collars are also a good idea. Wide collars spread pressure over more of the neck. This helps stop choking and makes the collar more comfy for big dogs. Some collars have reflective strips. These strips help your dog stay seen at night or in the dark. If you want to know more about reflective collars, visit the reflective dog collar product page.

If you want more comfy options, check out the daily commute dog collar collection. You will find collars for everyday use and long walks.

Comfort features do more than just feel nice. They help stop injuries and keep your dog healthy. When you pick a collar, think about what your dog needs. A good collar can make every walk safer and more fun.

Tip: Always look for collars with smooth edges and soft linings. These help protect your dog’s skin.

If you want more tips, you can read guides on the StridePaw blog.

Sampling Process for Dog Collars for Large Dogs

Creating a Design Brief or Tech Pack

You start your sampling journey by making a clear design brief or tech pack. This document tells your manufacturer exactly what you want. It helps you avoid mistakes and saves time. Here are some best practices to follow:

List all the features you want, like size, color, and material.

Add special features, such as bells, name tags, or reflective strips, to make your collars stand out.

Choose strong materials for both the collar and the packaging. This keeps your product safe and reusable.

Plan for bulk ordering if you want to save money on each collar.

Include drawings or photos to show your ideas.

Write down your logo placement and branding details.

A good tech pack makes it easier for your supplier to understand your needs. Many OEM partners, like those found in the daily commute dog collar collection, offer low minimum order quantities and sample customization. You can test your ideas without a big investment.

Tip: Always double-check your tech pack before sending it to your supplier. Clear instructions help you get the sample you want.

Sample Rounds and Adjustments

After you send your design brief, your supplier will make the first sample. This is your chance to see your ideas come to life. You should check the sample for quality, fit, and style. If something does not look right, write down your feedback.

Most brands go through several rounds of samples. Each round lets you fix problems and make improvements. You might want to change the color, adjust the size, or try a new material. Good communication with your supplier is key. Use photos and notes to explain what you want to change.

Here is a simple process you can follow:

Review the first sample for quality and design.

List any changes you want.

Share your feedback with your supplier.

Get a new sample with the updates.

Repeat until you are happy with the result.

You can learn more about sample adjustments and product development by reading the StridePaw blog.

Fit and Function Testing

You need to test your samples to make sure they work well for large dogs. Fit and function testing helps you find problems before you start mass production. Try the collar on different breeds and sizes. Check if the collar fits snugly but does not choke the dog.

Look for these things during testing:

The collar should not slip off or feel too tight.

The buckle and D-ring must hold up to strong pulling.

The material should not irritate the dog’s skin.

Extra features, like reflective strips, should work as promised.

Ask real dog owners to try the collar and share their feedback. This helps you spot issues you might miss. If you want to see a collar designed for safety and visibility, check out the reflective dog collar.

Note: Testing your samples with real users helps you build trust and avoid costly mistakes.

Fit and function testing is a key step in making high-quality dog collars for large dogs. When you follow these steps, you set your brand up for success.

Lab Tests and Certifications

You want your large-dog collars to meet the highest safety and quality standards. Lab tests and certifications help you prove that your collars are safe, strong, and ready for the market. When you work with trusted manufacturers, you can ask for lab tests from well-known labs like SGS, Bureau Veritas, UL, TUV, or Intertek. These labs check the raw materials and finished collars to make sure they are safe for pets and people.

Why do you need lab tests and certifications?

Lab tests show that your collars can handle the strength and wear that big dogs bring. Certifications help you sell your collars in the US, Europe, and other big markets. If you skip these steps, you risk product recalls, bad reviews, or even legal trouble.

Here are the main tests and certifications you should know:

Material Safety Tests: Labs check polyester, nylon, rubber, and printing inks for harmful chemicals. This keeps dogs safe from skin problems or allergies.

Tensile Strength Tests: These tests show how much force your collar can take before it breaks. Strong collars keep big dogs safe.

Crash Tests: Some collars need crash tests, especially if they are used for car travel.

Rust Resistance Tests: Metal parts like buckles and D-rings must not rust. Labs test them to make sure they last.

Chemical Safety Standards: Your collars must meet US CPSIA and European EN71-3 rules. These rules limit dangerous chemicals in pet products.

Tip: Always ask your supplier for test reports from labs like SGS or Intertek. This helps you check if your collars meet safety standards.

Key Certifications for Major Markets

Certification | Where Needed | What It Proves |

|---|---|---|

CE | Europe | Product meets EU safety rules |

UKCA | United Kingdom | Product meets UK safety rules |

CPSIA | United States | Product is safe for children and pets |

EN71-3 | Europe | Limits on chemicals in materials |

You need these certifications to sell in stores or online in many countries. Without them, your products may get stopped at customs or removed from shelves.

How to Get Started

Choose a manufacturer who works with trusted labs.

Share your design brief and ask for sample testing.

Review the test reports before you order in bulk.

Keep copies of all certifications for your records.

If you want to learn more about how to choose safe and certified collars, you can visit the StridePaw blog. For collars that meet high safety standards, check out the daily commute dog collar collection.

Remember: Lab tests and certifications protect your brand and your customers. They help you build trust and grow your business in new markets.

Mass Production and Quality Control

Finalizing Specs and Packaging

You need to confirm every detail before mass production begins. Start by reviewing your final sample. Make sure the size, color, and hardware match your brand’s standards. Double-check the materials for durability and comfort. You want your collars to look good and last a long time.

Packaging matters as much as the product. Choose packaging that protects the collar during shipping. Good packaging also helps your brand stand out in stores. You can use custom boxes, hang tags, or eco-friendly bags. Add your logo and brand colors to every package. This helps customers remember your brand.

Tip: Clear specs and strong packaging reduce returns and build trust with buyers.

If you want more ideas for packaging and branding, visit the StridePaw blog.

MOQ, Lead Time, Capacity Planning

When you plan your first big order, you need to know the minimum order quantity (MOQ). Most suppliers set MOQs between 500 and 5,000 units for custom heavy-duty collars. The MOQ depends on how complex your design is, what materials you choose, and how big the supplier’s factory is.

Lead time means how long it takes to make your collars. Sampling lead times usually range from 7 to 21 days. The time can change if your design is complicated or if materials are hard to find. If the factory is busy, you might wait longer.

Here is a quick guide:

MOQs for custom collars: 500–5,000 units

Sampling lead time: 7–21 days

Lead time changes with design, materials, and supplier workload

You should plan your order based on your sales goals and storage space. If you expect high demand, talk to your supplier about their capacity. Ask how many collars they can make each month. This helps you avoid delays and keeps your customers happy.

For more options and planning tips, check the daily commute dog collar collection.

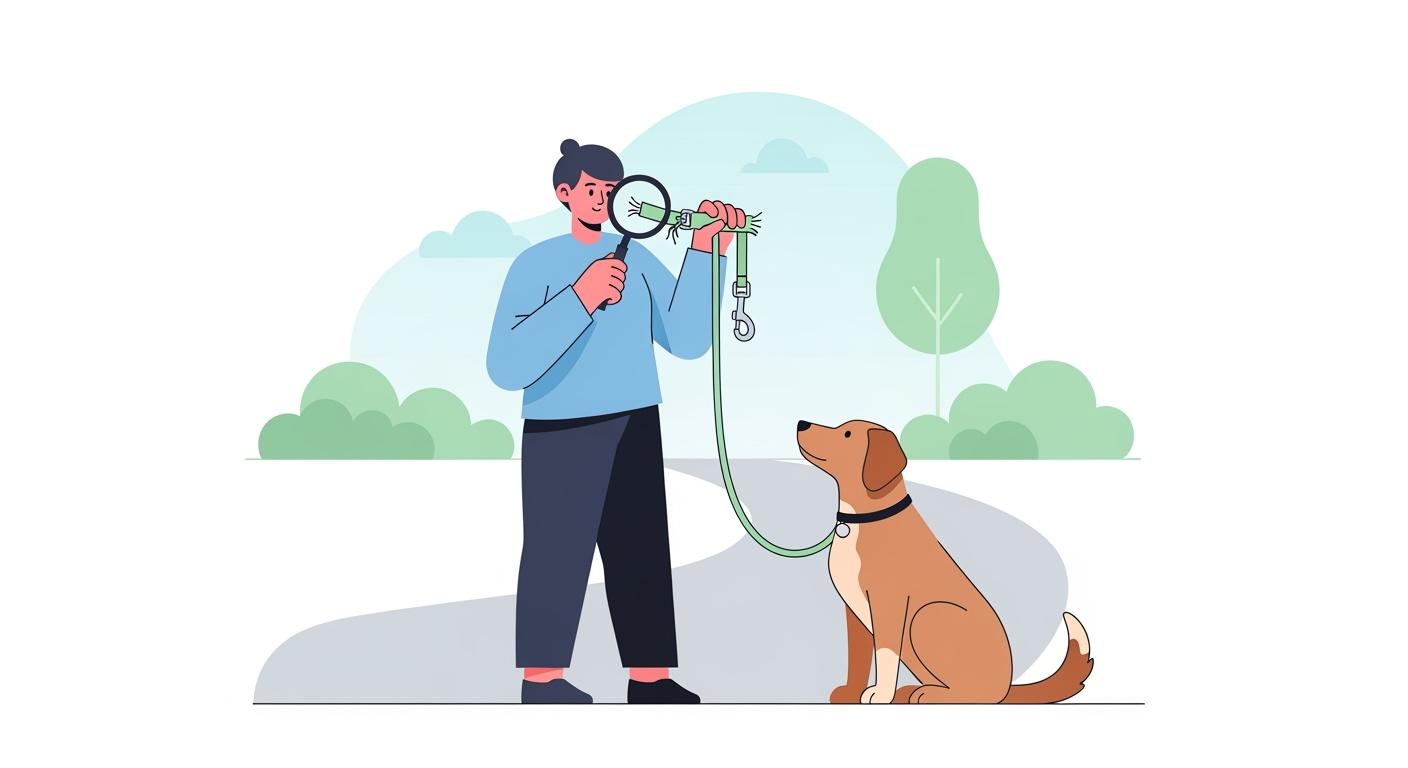

In-Line and Final QC Checks

Quality control (QC) keeps your collars safe and reliable. You need to check the collars during production and after they are finished. In-line QC means checking the collars while workers make them. You look for problems like loose stitching, weak buckles, or wrong colors. Fixing issues early saves time and money.

Final QC happens after production ends. Inspect each batch for size, strength, and comfort. Test the hardware to make sure it does not break or rust. Check the packaging for damage. You want every collar to meet your standards before shipping.

Here is a simple QC checklist:

Inspect stitching and seams for strength.

Test buckles and D-rings for durability.

Check color and logo placement.

Review packaging for protection and branding.

Note: Good QC helps you avoid returns and keeps your brand reputation strong.

If you want to see a collar that meets high safety standards, look at the reflective dog collar.

Shipping and Packing Best Practices

You want your large-dog collars to arrive safely and look great when customers open the box. Good shipping and packing practices help you protect your products and your brand. You can follow these best practices to make sure your collars reach their destination in perfect condition.

First, organize your warehouse. When you set up your warehouse in a smart way, you make picking and packing faster. You lower the chance of mistakes and damage. Place heavy-duty collars in easy-to-reach spots. Use clear labels for each style and size. Workers can find items quickly and pack them with care.

Next, check your packing process often. Quality control matters at every step. You should inspect each collar before packing. Look for loose stitching, broken hardware, or missing tags. If you find a problem, fix it before shipping. This helps you avoid returns and unhappy customers.

Choose strong packing materials. Use sturdy boxes that fit the collars well. Add padding, like bubble wrap or recycled paper, to stop collars from moving around. Seal each box with strong tape. If you ship many collars together, use dividers to keep them from rubbing against each other.

Eco-friendly packaging works well for large-dog collars. You can use recycled cardboard or biodegradable bags. Many customers care about the environment. Green packaging helps you meet regulations and attract buyers who want sustainable products. You show your brand values by choosing earth-friendly options.

Label each package clearly. Put the product name, size, and color on the outside. Add your logo and brand colors to the box or bag. This helps your collars stand out and makes your brand easy to remember.

Here are some tips to help you ship and pack collars the right way:

Organize your warehouse for fast and safe picking.

Inspect each collar before packing.

Use strong boxes and padding to protect collars.

Choose eco-friendly packaging to meet rules and please customers.

Label packages with product details and your brand logo.

Tip: Regular checks during packing help you catch mistakes early. You save money and keep your customers happy.

If you want to see more options for everyday collars and learn about packing for travel, visit the daily commute dog collar collection. You can find collars that ship well and look great in stores.

Good shipping and packing practices help you build trust. You show customers that you care about quality and safety. When you follow these steps, you protect your products and your reputation.

Compliance and Documentation

Chemical and Material Safety

You need to watch out for chemical and material safety when making dog collars for large dogs. Safety rules help keep pets and people safe from bad chemicals. In the US and Europe, you must follow strict laws before selling collars.

Here are some rules you should know:

REACH checks for dangerous chemicals and heavy metals in pet products. If your collar has Substances of Very High Concern over 0.1%, you must register them.

The General Product Safety Directive (GPSD) makes sure pet collars are safe before people buy them in the EU.

The Flammable Fabrics Act (FFA) sets rules for how easy it is for pet textiles to catch fire in the US.

You also need to look at Annex XVII to REACH. This list shows chemicals that are banned or limited in products for people and pets. Tests like EN 71-2 for flammability and EN ISO 12952-1 for ignitability are used for pet collars. These tests help you show your collars are safe.

Tip: Always ask your supplier for test reports and certificates. This helps you avoid trouble with customs and keeps your customers safe.

If you want to see more safe and strong collar choices, visit the daily commute dog collar collection.

Mechanical Safety for Large-Dog Collars

Mechanical safety means your collars must be tough and work well. You need to make sure the hardware, stitching, and materials can handle strong dogs. Weak collars can break and cause accidents.

Check these things for mechanical safety:

Use strong buckles and D-rings made from stainless steel or brass.

Test the collar’s tensile strength to see how much force it can take before breaking.

Make sure stitching is tight and does not come apart.

Avoid sharp edges or rough spots that can hurt a dog’s skin.

You should follow safety rules for pet products. Many brands use EN 71-1 for mechanical and physical properties. This rule checks for choking hazards and sharp points. You keep dogs safe by following these rules.

Note: Regular safety checks help you find problems early and protect your brand.

Required Documentation for B2B Buyers

You need the right papers to buy and sell dog collars for large dogs in bulk. These papers show your collars meet safety and quality rules. They also help you get through customs and avoid delays.

Here is a table of common papers you should have:

Document Type | Purpose |

|---|---|

Test Reports | Show results for chemical and mechanical safety |

Certificates | Prove compliance with US and EU rules |

Material Declarations | List all materials and chemicals used |

Product Specifications | Describe size, weight, and features |

Packing List | Details each item in your shipment |

You should keep copies of all certificates and test reports. Share them with your buyers and distributors. This helps build trust and grow your business.

Tip: Good paperwork makes your supply chain smoother and keeps your products selling.

If you want more tips on compliance and documentation, you can read guides on the StridePaw blog.

Extra Compliance for Special Collars

Some dog collars need more safety checks. If you want to sell GPS collars, reflective collars, or training collars for large dogs, you must follow extra rules. These collars have special technology or materials. You need to check safety and legal rules before selling your product.

You should know about these special collar types:

GPS Collars: These collars have batteries and electronic chips. You must follow rules for electronics and battery safety. In the United States, you need FCC certification for wireless devices. In Europe, you need CE marking for electronics. You must test for electromagnetic safety and battery leaks.

Reflective Collars: These collars use reflective tape or paint. You must check for chemical safety. Some reflective materials have chemicals that can hurt pets. You need to test for skin irritation and chemical limits. You should follow EN71-3 standards for chemical safety in Europe.

Training Collars: Some collars use vibration or sound. You must test for safe levels. You should not use collars that hurt or scare dogs. You need to follow animal welfare laws in your country.

Tip: Always ask your supplier for extra test reports if your collars use electronics or special coatings. This helps you avoid recalls and keeps pets safe.

Here is a table to help you see what extra compliance you need for each collar type:

Collar Type | Extra Compliance Needed | Key Tests or Certifications |

|---|---|---|

GPS Collar | Electronics, battery safety | FCC (US), CE (EU), RoHS |

Reflective Collar | Chemical safety, skin safety | EN71-3, skin irritation tests |

Training Collar | Animal welfare, sound/vibration | Local animal welfare laws |

You must keep all extra certificates and test reports. You should share them with your buyers and distributors. This builds trust and helps you sell in more places.

If you want to see more collars for daily use and travel, visit the daily commute dog collar collection. You can find collars that meet safety rules and work for special needs.

You should also read guides on the StridePaw blog to learn more about compliance for special collars. If you want a collar with extra safety features, check out the reflective dog collar.

Note: Extra compliance keeps your business safe and protects pets. Always check the rules for your collar type before you start selling.

Launching Your Private Label Dog Collars for Large Dogs

Pre-Launch Checklist

You need a checklist before you start selling. This helps you avoid mistakes and makes your launch easier. First, check your final samples. Make sure each collar matches your size, color, and hardware needs. Look at your packaging. See if it protects the collar and shows your brand. Confirm that safety tests and certifications are finished. Check your inventory. Make sure you have enough collars for your first orders. Get your marketing materials ready, like photos and descriptions. Teach your team about the collars and how to help customers.

Here is a simple checklist to follow:

Check your final samples.

Confirm packaging and branding.

Make sure safety tests are done.

Prepare your inventory and storage.

Get marketing materials ready.

Train your team.

Tip: Use a checklist to find small problems before they get bigger.

Collecting Feedback and Reducing Returns

After you launch, listen to your customers and distributors. Feedback helps you know what works and what needs fixing. Ask distributors what they think about quality and packaging. Talk to early customers and ask them to share their thoughts. Use surveys, online reviews, or messages to get feedback. Look for common problems, like sizing or hardware issues. If you see the same problem often, fix it fast. Offer easy returns and exchanges. This helps customers trust your brand.

Here is a table to help you track feedback and lower returns:

Feedback Source | What to Ask | How to Use the Info |

|---|---|---|

Distributors | Product quality, packaging | Make shipments better |

Early Customers | Fit, comfort, durability | Change specs or sizing |

Online Reviews | Likes and dislikes | Update product info |

Note: Fixing problems quickly keeps customers happy and lowers returns.

You can learn more about feedback and making your products better by visiting dog collar industry insights.

Planning New Features and Extensions

Always look for ways to make your collars better. Watch for new trends in pet products. Ask customers what features they want next. You might add new colors, eco-friendly materials, or smart tech. Review your product line often. Test new ideas with small batches before selling to everyone. Work with suppliers to create new designs and features. This keeps your brand fresh and strong.

Tip: Checking your products often helps you stay ahead and keeps customers coming back.

If you want to learn more about private label dog collars and planning new features, you can learn more about private label dog collars.

You can make a great private label dog collar line for large dogs if you follow every step. Pick suppliers you trust. Always check for good quality. Make sure you follow safety rules. Use checklists to help you stay organized. Ask people what they think about your collars. Their feedback helps you make your products better. If you want more ideas, look at the daily commute dog collar collection.

Grow your business and use local suppliers for long-lasting success.

FAQ

What materials work best for large-dog collars?

You should choose strong materials like nylon, leather, or Biothane. These materials last a long time and resist wear. For more options, visit the daily commute dog collar collection.

How do you measure your dog’s neck for a collar?

Use a soft tape measure. Wrap it around your dog’s neck where the collar sits. Add two fingers between the tape and neck for comfort. This helps you pick the right size.

What safety features should you look for in large-dog collars?

Look for reflective strips, sturdy buckles, and rust-proof D-rings. These features keep your dog safe during walks. For extra visibility, check out the reflective dog collar.

How can you customize private label dog collars?

You can add your logo, choose custom colors, and select unique packaging. Many suppliers offer embroidery, printing, or special tags. Customization helps your brand stand out.

What tests ensure collar safety and quality?

Manufacturers use tensile strength tests, chemical safety checks, and rust resistance tests. These tests make sure collars stay strong and safe for large dogs.

How do you reduce returns after launch?

You should collect feedback from customers and distributors. Fix common problems quickly. Offer easy returns and exchanges. For more tips, read the StridePaw blog.

Are eco-friendly collars available for large dogs?

Yes! Many brands now offer collars made from recycled nylon or plant fibers. These collars help protect the planet and keep your dog safe.

How often should you replace a large-dog collar?

Check your dog’s collar every few months. Replace it if you see fraying, broken hardware, or signs of wear. Regular checks keep your dog safe.