You get lots of returns and complaints when micro buckles or micro rings break in collars for little dogs. These weak spots can let dogs escape or get hurt. Picking the right collar is very important for your business. The risks are more than just losing sales:

Risk/Consequence | Description |

|---|---|

Physical Damage | Old collars can squeeze blood vessels and press on the thyroid gland. |

Nerve Damage | Collars that pull may hurt nerves and harm the dog’s health. |

Tracheal Collapse | Small breeds can have tracheal collapse from collar pressure. |

Glaucoma Exacerbation | Collars can make glaucoma worse by raising eye pressure. |

You need to choose collars for little dogs that meet WL, PL, and UT from the Card to lower these risks. Even a small 2% drop in returns helps you make more money on every order. Use the Card’s AQL and defect rules. Ask for a price or samples, or get a catalog from StridePaw. For safety, look at StridePaw’s Collars for Dogs That Prioritize Safety Features. Check out StridePaw’s newest collar collection. Contact StridePaw to get a price.

Key Takeaways

Pick collars with strong micro hardware. This stops escapes and injuries. Weak buckles can be very risky.

Correct measurements are very important for collar fit. Use the two-finger rule for comfort and safety.

Choose the right closure type for safety. Side-release buckles and martingale collars help small dogs in different ways.

Check collars often for edge hazards. Watch for fraying, sharp edges, or other dangers.

Use a quality control plan with the Card’s AQL and defect rules. This finds problems before you sell collars.

Know why pull strength targets matter. Match collars to the working load, proof load, and ultimate strength for safety.

Ask suppliers for samples and quotes to compare collars. This helps you pick the best quality for your customers.

Teach customers how to use collars and about safety features. Clear packaging and guides can lower returns.

Micro-Hardware Failure in Collars for Little Dogs

What Is Micro Hardware in Collars

You need to understand what micro hardware means for miniature dog collars. Micro hardware includes the small buckles, D-rings, and adjusters that hold the collar together. These parts must fit the size and weight of little dogs. If you choose the wrong hardware, you risk escapes, injuries, and high return rates. You should always match the hardware to the WL, PL, and UT from the Card for your target weight class.

Common Failure Modes: Buckle, D-Ring, Stitching

Micro hardware often fails before the webbing does. You may see buckles pop open, D-rings spread, or stitching break. Each failure can lead to a dog escaping or getting hurt. You must spot these risks early in your sourcing process.

Failure Mode Table: Escape Scenarios

Buyer Symptom | Likely Root Cause | Spec or Test to Prevent It |

|---|---|---|

Dog escapes on leash jerk | Buckle pops open | Use Card’s PL buckle test, cycle test |

D-ring bends or spreads | Weak or thin D-ring | Use Card’s UT for D-ring, salt fog |

Collar slips off neck | Adjuster slippage | Cycle test, slippage check at PL |

Webbing frays at edge | Sharp hardware edge | Edge-finish acceptance, sharp edge test |

Buckle cracks after use | Low-grade material | Card’s cycle target, material spec |

You can use this table to guide your supplier checks and RFQs. Always request a quote and ask for samples or get a catalog from StridePaw to compare hardware quality.

Why Escapes Happen Despite Good Webbing

You may think strong webbing is enough for miniature dog collars. In reality, micro hardware is often the weak point. A collar with good webbing but poor hardware can still fail. You must check that the buckle, D-ring, and adjuster all meet the Card’s WL, PL, and UT. Look for signs like loose fit, thin D-rings, or rough edges. These can lead to escapes or injuries.

Tip: Use the Card’s AQL and defect definitions to set your QC plan. This helps you catch hardware issues before launch.

A small drop in your return rate can boost your gross margin. For example, if you reduce returns by just 2% on a 1,000-unit order, you keep 20 more sales. That adds up over time. Use the Card’s WL/PL/UT to justify the cost of better hardware for miniature dog collars.

You can see more safety features in StridePaw’s Collars for Dogs That Prioritize Safety Features. For product options, visit the StridePaw collar collection page. Ready to improve your sourcing? Request a quote or ask for samples / get a catalog from StridePaw. For direct help, contact StridePaw.

Fit and Escape Prevention for Small Dogs

Measurement Points for Best Collar Fit

You need to measure accurately when choosing a small dog collar for your assortment. Accurate sizing reduces escapes and returns. Follow these steps to get the best fit for little dogs:

Use a soft measuring tape, tape measure, or string.

Wrap it around the base of the dog’s neck, just above the shoulders. Make sure it is snug but not tight.

Record the measurement in inches or centimeters.

If you use string, mark where it overlaps and measure the length for neck circumference.

You should always apply the two-finger rule. Place two fingers between the collar and the dog’s neck. This ensures the collar is snug but not too tight. A collar that is too loose can slip off. A collar that is too tight can cause discomfort or injury. For small dogs, select a collar width of 1–1.5cm. This width balances comfort and security. Regularly check the fit, especially for growing dogs or those with changing fur thickness.

Tip: For more details on sizing and width, see StridePaw’s Collars for Little Dogs: Safety-Focused Sizing and Width Solutions for Pet Retailers.

You must define your target dog weight class before you set your WL, PL, and UT requirements. Use the Card’s WL/PL/UT to justify cost of better hardware. This step helps you avoid escapes and injuries.

Neck, Fur Compression, Adjustment Range

You should measure at the base of the neck, where the collar will sit. Consider fur compression. If the dog has thick fur, press the fur down gently when measuring. This prevents the collar from being too loose once the fur compresses. Always check the adjustment range of the collar. The collar should allow for some adjustment, but not so much that it becomes unstable or slips off.

Note: Regular checks on collar fit are essential. Dogs can gain or lose weight, and fur can change with the seasons.

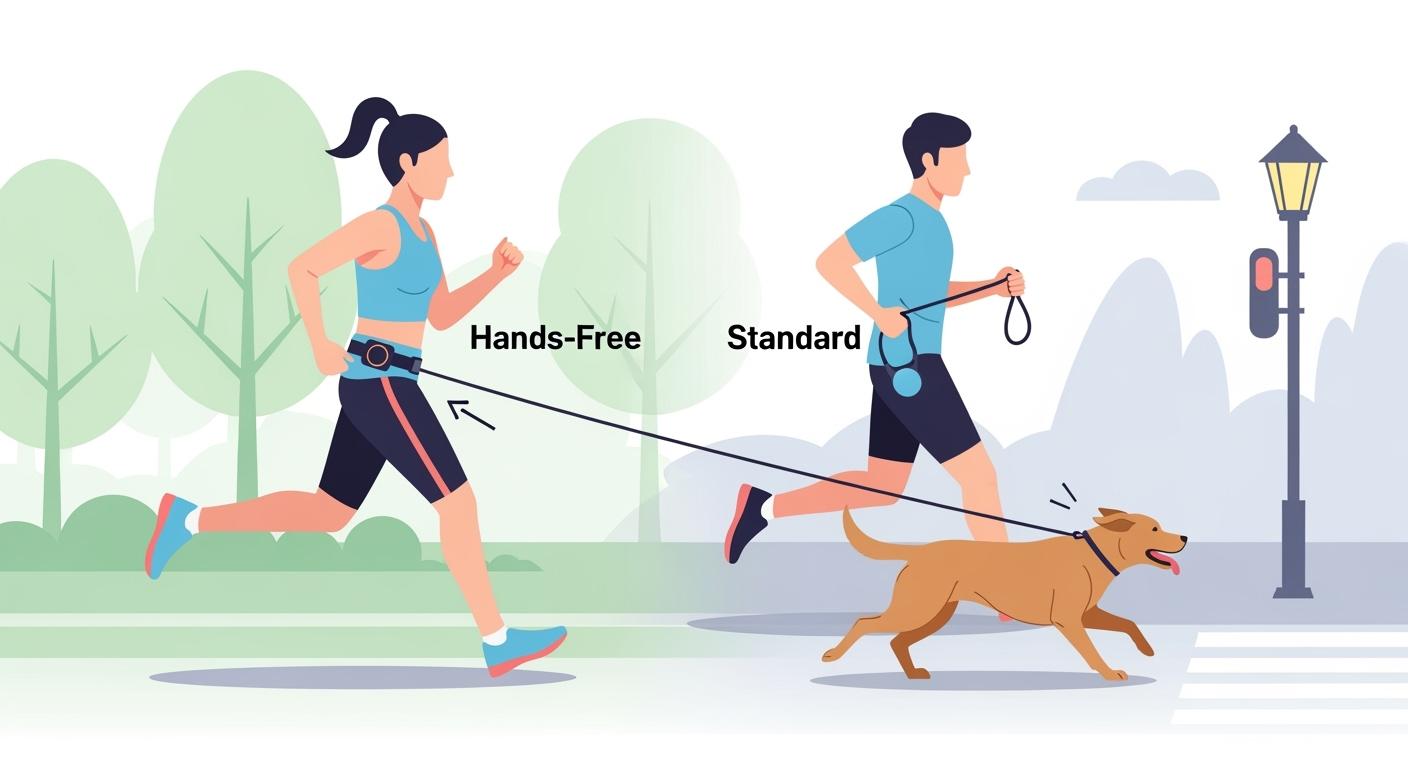

Closure Types and Fit Stability

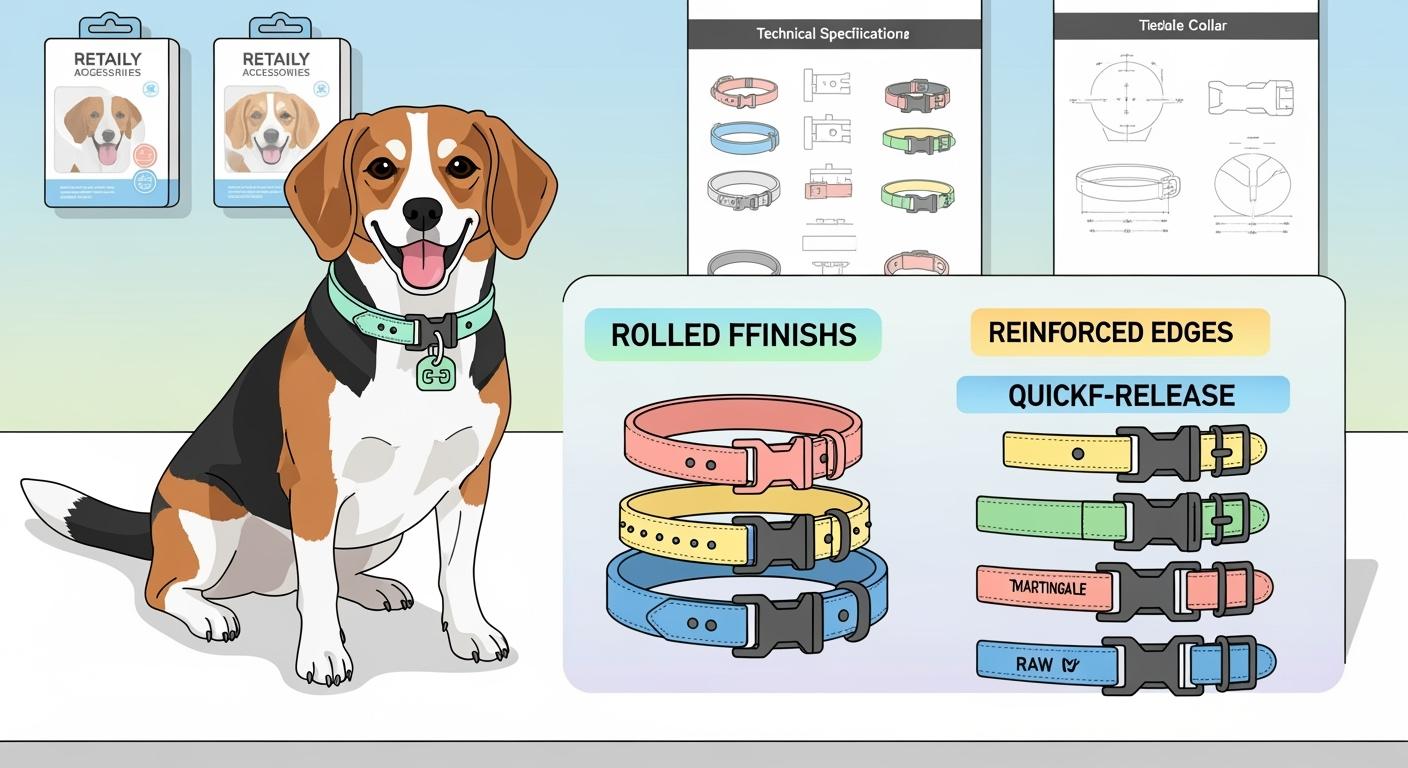

You need to select the right closure type for fit stability when choosing a small dog collar. The closure impacts both safety and ease of use. Here are the most common closure types for small dog collars:

Side Release Buckle: This buckle is reliable and easy to use. It provides a secure fit for small dogs.

Martingale Collar: This design tightens gently when the dog pulls. It offers better control without causing discomfort. It is suitable for dogs that might slip out of traditional collars.

Limited Slip Collar: This collar tightens slightly when the dog pulls. It prevents slipping and gives gentle control. It works well for small dogs that back out of regular collars.

You should match the closure type to your target market and use case. Always request a quote or ask for samples / get a catalog from StridePaw to compare closure options and hardware quality.

Side-Release, Martingale, Dual D-Ring

Side-release buckles are common for retail and e-commerce channels. Martingale and dual D-ring designs offer extra security for dogs that tend to slip out. You should define your closure type in your RFQ and spec pack. This ensures your supplier understands your requirements.

Request a quote from StridePaw or ask for samples / get a catalog to review closure types and fit stability.

Friction, Slippage, and Micro Hardware

Friction between the webbing and hardware affects collar stability. Low friction can lead to slippage, even if the collar passes pull strength tests. You should specify a cycle test and slippage check at PL in your test plan. Use the Card’s AQL and defect definitions to set your QC plan. This helps you catch slippage or hardware issues before launch.

A small drop in your return rate can boost your gross margin. For example, if you reduce returns by just 2% on a 1,000-unit order, you keep 20 more sales. That adds up over time.

For more safety features, see StridePaw’s Collars for Dogs That Prioritize Safety Features…. To view product options, visit the StridePaw collar collection page.

You can improve your sourcing process by using the Card’s WL/PL/UT and AQL rules. Ready to take the next step? Get a quote or Contact Us at StridePaw.

Choosing the Best Collar for Small Dogs: Fit and Safety

You want to select the best collar for small dogs that meets both fit and safety requirements. Start by defining your target dog weight class. This step helps you set the right WL, PL, and UT from the Card. Accurate measurement is essential. Use a flexible tape to measure the dog’s neck at the base, pressing gently if the dog has thick fur. Make sure the collar sits lower than the larynx, closer to the shoulders. Always check that two fingers fit between the collar and the neck. This prevents the collar from being too tight or too loose.

Tip: Use the Card’s AQL and defect definitions to set your QC plan. This helps you catch issues before launch.

You should look for these key criteria when sourcing collars:

Criteria | Description |

|---|---|

Size | Collar should lie flat, not slip over the head, and sit at the base of the neck. |

Material | Choose strong, non-irritating materials like nylon or leather. |

Safety Features | Adjustable fit, solid closures, and D- or V-shaped rings for leash attachment. |

You need to consider closure type and webbing friction. Side-release buckles work well for most retail channels. Martingale and dual D-ring designs add extra security for dogs that tend to slip out. Always specify your closure type in your RFQ and spec pack. This ensures your supplier understands your requirements.

Ensure the collar does not slip over the dog’s head.

Measure the neck with a flexible tape, allowing two fingers between collar and neck.

Consider martingale-style collars for better fit and safety.

You should request a cycle test and slippage check at PL. This step confirms that the collar will not slip or open under normal use. Use the Card’s WL/PL/UT to justify cost of better hardware. This reduces escapes, injuries, and returns.

A small change in your return rate can impact your gross margin. For example, if you reduce returns by 2% on a 1,000-unit order, you keep 20 more sales. That adds up over time.

Request a quote or ask for samples / get a catalog from StridePaw to compare fit, closure, and hardware options.

You can see more safety features in StridePaw’s Collars for Dogs That Prioritize Safety Features. For product options, visit the StridePaw collar collection page.

You can improve your sourcing process by following these steps: define your target dog weight class, set WL/PL/UT, choose buckle type, define cycling test, define edge-finish acceptance, set QC sampling, then launch a pilot order. For direct help, visit StridePaw Get A Quote.

Micro Buckle Spec Pack and Compatibility

When you pick a small dog collar, the micro buckle is very important. The right buckle helps keep the collar safe, strong, and fitting well. You need to match the buckle’s material, shape, and slot size to your market and product level.

Acetal vs Metal Buckles

Acetal buckles are light and do not react with chemicals. They work for most stores and online shops. Acetal is good for cheaper and middle-priced collars. Metal buckles are stronger and feel more expensive. They are best for special, outdoor, or fancy collars. You should decide your sales channel and price before picking a buckle.

Channel and Price Tier Logic

Retail/E-commerce (Value/Mid-tier): Acetal buckles are enough for most uses. They keep collars light and cost low.

Specialty/Luxury/Outdoor: Metal buckles are stronger and look nicer. They work for higher prices and tough use.

Tip: Use the Card’s WL/PL/UT to show why better hardware is worth it for your small dog collars.

Anti-Pop-Open Design Features

You want to stop the buckle from opening by accident. Anti-pop-open features make collars safer and more reliable. Look for these features when checking samples or supplier details:

Feature | Specification | Benefit |

|---|---|---|

Safety Mechanism | Ladder lock slider with anti-slip design | Stops buckle from opening under pressure |

Enhanced Anti-Slip | Textured or ribbed contact surfaces | Lowers chance of buckle opening by mistake |

Multi-Layer Locking Mechanism | Dual or triple latch engagement | Makes sure buckle stays closed under force |

You should ask for these features in your RFQ. Tell your supplier to show how the buckle stays closed during tests. For more safety ideas, see StridePaw’s Collars for Dogs That Prioritize Safety Features….

Buckle Slot and Webbing Compatibility

The buckle slot must fit the webbing’s width and thickness. If it does not fit, the collar can slip or break early. You need to pick the slot size based on your webbing. For example, if your webbing is 2.0 ± 0.1 mm thick and folds to 4.0 ± 0.15 mm, use a 2 mm slot. This gives a tight, safe fit.

Webbing Thickness | Total Fold-over | Slot Hardware |

|---|---|---|

2.0 ± 0.1 mm | 4.0 ± 0.15 mm | 2 mm |

Note: Always check slot and webbing fit when you get new collars. This helps you avoid slipping and fitting problems.

Spec Request Checklist Table

Use this checklist to help with your RFQ and QC steps. It covers what you need for hardware, slot/webbing fit, and anti-pop-open features.

Requirement | What to ask the supplier for | How to verify at receiving |

|---|---|---|

Buckle Material | Acetal or metal (pick by channel/price) | Look at it, check material test report |

D-Ring Material | Stainless or coated metal, must not rust | Salt fog test (Card baseline), look at it |

Anti-Pop-Open Features | Ladder lock, anti-slip, multi-layer locking | Try it out, cycle test at Card’s cycle target |

Slot/Webbing Fit | Slot fits webbing width/thickness | Measure both, test for slipping |

Cycle Durability | Meets Card’s cycle target (like 3000 cycles) | Cycle test, check after test |

Pull Strength | Meets Card’s WL/PL/UT for weight class | Pull test, check for opening or slipping |

Edge Finish | No sharp edges, no burrs, no fraying | Look and feel, check for sharp spots |

Documentation | Test reports, batch tracking | Check papers, match lot numbers |

Use the Card’s AQL and defect rules to set your QC plan. This helps you find hardware or fit problems before selling.

You can make more money by lowering returns. For example, if you cut returns by 2% on 1,000 collars, you keep 20 more sales. This helps your profit. Use the Card’s WL/PL/UT to show why better hardware is worth it.

You should follow these steps to source collars:

Pick your target dog weight class.

Set WL/PL/UT from the Card.

Choose buckle type (acetal or metal) by channel and price.

Ask for anti-pop-open features.

Match buckle slot to webbing size.

Set cycling and pull strength tests.

Set edge-finish rules.

Use AQL sampling for QC.

Start with a pilot order.

Ask for a quote or samples / get a catalog from StridePaw to compare buckle types and hardware quality.

You can see more safety features in StridePaw’s Collars for Dogs That Prioritize Safety Features…. For more products, visit the StridePaw collar collection page. Want to improve your sourcing? Visit StridePaw Get A Quote.

Buckle Cycling and Durability Testing

You have to make sure every micro buckle on small dog collars works well every day. The buckle must last through tough use. This keeps your customers and your business safe. You can use a simple step-by-step plan to check how strong and durable the buckles are.

Cycle Test and Pass Criteria

First, pick your target dog weight class. Use the Card’s WL, PL, and UT to set how strong the buckle needs to be. Next, pick your buckle type based on where you will sell and your price range. Then, set up your cycling test. The Card’s cycle target tells you how many times the buckle should open and close, both with and without weight.

Test Plan Matrix: Test Name, Method, Acceptance, Sampling

You can use this test plan matrix to help your supplier and QC team:

Test Name | Method (Summary) | Acceptance Criteria | Sampling Plan (AQL) |

|---|---|---|---|

Buckle Functional Cycle | Open/close buckle (no load), Card’s cycle target | No unintended release, no visible cracking, clear lock | Card’s AQL (Critical: 0) |

Loaded Cycle Durability | Cycle buckle under load (within WL/PL) | No abnormal slippage, no cracks, still locks | Card’s AQL (Major: 2.5) |

Pull Strength | Pull to WL, PL, UT (see Card) | No release/slip/crack at PL, meets UT | Card’s AQL (Critical: 0) |

Salt Fog Exposure | Expose to salt fog (Card’s hours, ASTM B117) | No noticeable corrosion, passes post-exposure PL test | Card’s AQL (Major: 2.5) |

Use the Card’s AQL and defect rules to set your QC plan. This helps you find problems before you sell the collars.

Recording Deformation and Latch Wear

You should write down any changes or latch wear after each test. Look for cracks, worn latch teeth, or loose locking. If you see these problems, the buckle may not be safe to sell. Always check for slipping after cycling and pull tests. If a buckle passes the test but slips, you need to change your hardware or webbing.

Use the Card’s WL/PL/UT to show why better hardware is worth it. Even a small drop in returns can help you earn more. For example, if you lower returns by 2% on 1,000 collars, you keep 20 more sales.

After-Exposure Testing: Corrosion and Humidity

You must check that metal hardware does not rust or get damaged by humidity. Use the Card’s salt fog exposure baseline and ASTM B117 method. After the test, open and close the buckle and do the PL test again.

The rules for corrosion resistance testing include putting hardware in salt spray and drying it. After testing, look at all important surfaces for rust. Only the edges can have a little rust. Hardware must stay safe and work well.

Attachment hardware must not have rust on important surfaces after testing. You can use special coatings to stop rust, as explained in ASTM B456.

You can see more safety features in StridePaw’s Collars for Dogs That Prioritize Safety Features…. For more products, visit the StridePaw collar collection page.

You can make your sourcing process better by following these steps: pick your target dog weight class, set WL/PL/UT, choose buckle type, set cycling test, set edge-finish rules, set QC sampling, then start with a pilot order.

Ready to move forward? Ask for a quote or samples / get a catalog from StridePaw. For help, visit StridePaw Get A Quote.

Pull Strength and Load Targets for Little Dogs

Working, Proof, and Ultimate Load Definitions

You need to set clear pull strength targets when sourcing collars for little dogs. The Card gives you three key baselines:

Working Load (WL): This is the average force from a leash jerk. Use WL to check that the collar holds up during normal use.

Proof Load (PL): This is double the WL. PL checks that the collar does not slip, crack, or release under strong force.

Ultimate Strength Target (UT): This is the highest force the collar must survive. UT scales with the dog’s weight class. For little dogs (2–10 kg), use the Card’s UT range.

You should always match your collar’s hardware and webbing to these baselines. This step helps you avoid escapes and injuries. Use the Card’s WL/PL/UT to justify cost of better hardware. Even a small improvement in hardware can lower your return rate and boost your gross margin.

Example: If you reduce returns by 2% on a 1,000-unit order, you keep 20 more sales. Use the Card’s AQL and defect definitions to set your QC plan and protect your margin.

Test Setup for Real Leash Angles

You want your test setup to reflect real-world leash forces. Dogs and handlers pull at different angles and strengths. Studies show that leash tension changes with behavior and environment. You should design your tests to match these scenarios.

Study | Key Findings |

|---|---|

Shih et al. | Leash tension varies with dog or handler pulling. Direction and force change with behavior. |

Van Hernwijnen et al. | Leash tension increases in challenging environments. Both dog and handler affect tension. |

Set up your test rig to allow for different leash angles. Pull the collar at the WL and PL from the Card. Check for slippage, opening, or deformation. This approach helps you catch weak points before launch.

Tip: Always test with the leash attached to the D-ring at angles that match real walking and pulling.

Addressing Slippage After Passing Tests

Sometimes a collar passes pull strength tests but still slips during use. You need to address this before you launch your product. Here are steps you can take:

Use a limited slip collar for small dogs or sensitive breeds. This design helps prevent slippage.

Introduce puppies to contrast training with a limited slip collar that has a brake mechanism. This limits tightening and improves control.

Fit the dog with a slip collar and use a quick, firm motion to tighten briefly, then release. This helps correct fit and reduces slippage.

You should always check for slippage after cycling and pull tests. If you find slippage, adjust your hardware or webbing choice. Use the Card’s AQL and defect definitions to guide your QC checks.

For more safety features, see StridePaw’s Collars for Dogs That Prioritize Safety Features….

You can improve your sourcing process by following these steps: define your target dog weight class, set WL/PL/UT, choose buckle type, define cycling test, set edge-finish acceptance, set QC sampling, then launch a pilot order.

Request a quote or ask for samples / get a catalog from StridePaw to compare hardware and fit options. For product options, visit the StridePaw collar collection page. Ready to move forward? Visit StridePaw Get A Quote.

Edge-Finish and Safety Requirements

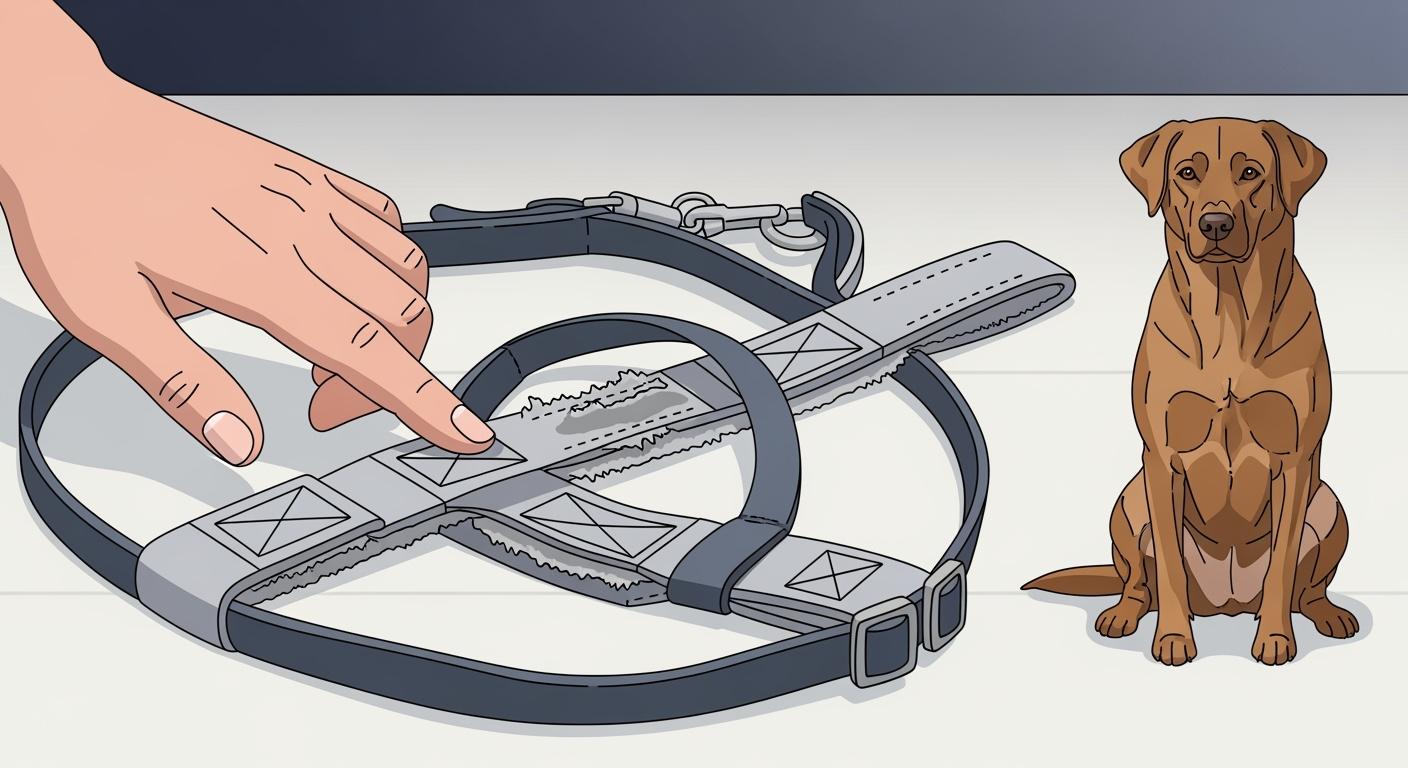

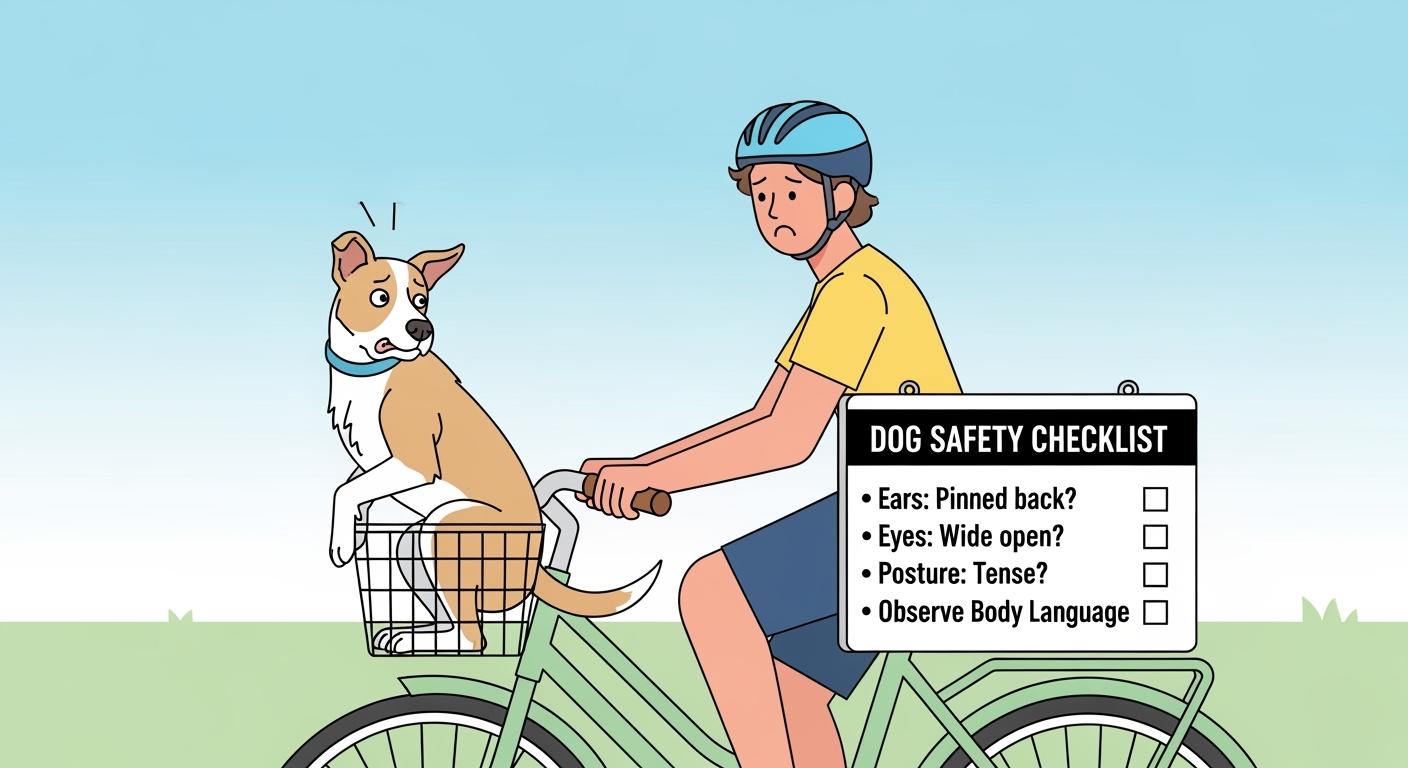

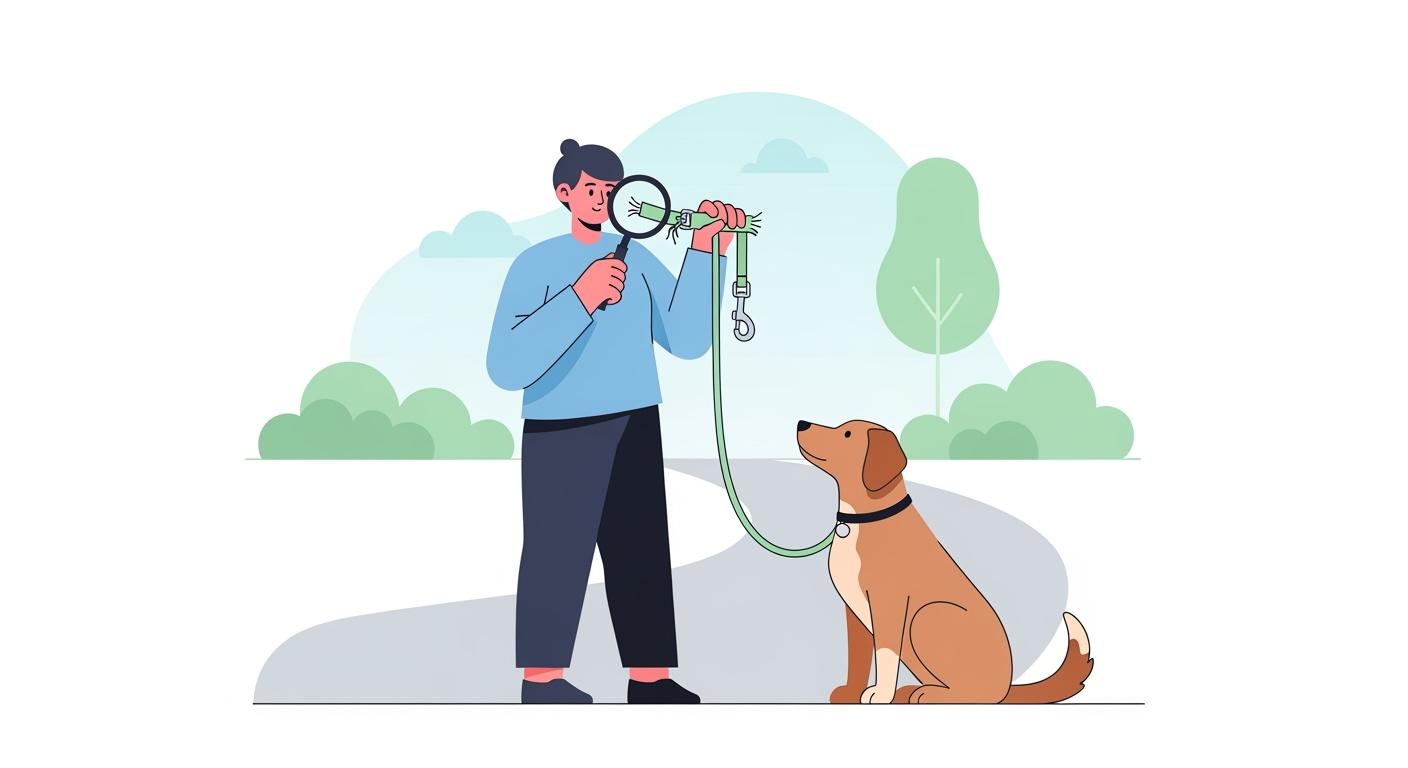

Identifying Edge Hazards

You need to check every collar for edge hazards before approving a batch. Edge hazards can hurt little dogs by causing skin problems or fur damage. Sometimes, they can even cause injuries. When you inspect collars, look for these problems: visible wear like fraying or stiff spots, broken hardware such as rusty or stuck buckles, poor fit that you can check with the two-finger rule, faded or hard-to-read ID tags that make it hard to find lost dogs, and bad smells that might mean bacteria is growing. You should replace collars every 6 to 12 months, depending on how much they are used and what you find during checks. Finding these problems early helps you lower returns and keep your brand safe.

Tip: Use the Card’s AQL and defect definitions to set your QC plan. This helps you find edge hazards before you sell collars.

Edge Finishing Options

There are different ways to finish collar edges and make them safer. Each way gives a different look and level of safety.

Binding, Fold-Over, Edge Paint, Heat Cut

Binding: You can cover raw edges with a fabric or synthetic strip. This makes the edge smooth and stops fraying.

Fold-Over: You can fold the webbing back and sew it down. This hides the cut edge and makes the collar stronger.

Edge Paint: You can put a special coating on the edge to seal and smooth it. This works well for leather or synthetic collars.

Heat Cut: You can use heat to melt and seal the edge of the webbing. This stops fraying and makes the edge round.

Pick the edge finish that fits your market and price range. Always check that the edge does not have sharp points or burrs.

For more safety features, see StridePaw’s Collars for Dogs That Prioritize Safety Features….

Acceptance Language for Sharp Edges

You must use clear words in your RFQ and QC documents about sharp edges. The Card’s rules say: “No sharp edges or sharp points on hardware or cut webbing ends,” “No burrs that can rub or scratch webbing or skin,” and “No fray at cut ends.” You should follow the U.S. sharp edge and point test for consumer products. This means you check all hardware and webbing by touching and looking. If you find anything sharp, the collar does not pass.

Request a quote or ask for samples / get a catalog from StridePaw to compare edge finishes and safety features.

A small drop in your return rate can help you earn more money. For example, if you lower returns by 2% on a 1,000-unit order, you keep 20 more sales. Use the Card’s AQL and defect definitions to protect your profit. Use the Card’s WL/PL/UT to show why better hardware and edge finishing are worth it.

You can see more options in the StridePaw collar collection page. Ready to make your sourcing better? Visit StridePaw Get A Quote.

QC, Sampling, and Documentation

Quality control keeps your brand safe and helps you avoid returns. You need a simple plan for checking, sampling, and keeping records. This section explains each step so you can sell small dog collars that are safe and follow the rules.

Incoming Inspection Checklist

Check every batch when you get a shipment. Use a checklist to see if each collar matches your order and safety rules. The table below shows what to check during inspection:

Checklist Item | Description |

|---|---|

Manufacturer & Supplier Details | Write down who made and sent the collars. |

Purchase Order Number | Make sure the shipment matches your order. |

Material Name & Description | Check the collar type and details. |

Purchase Order Specifications | See if collars meet your needed specs. |

Are there minor/major defects? | Look for any problems during inspection. |

Tagging (Accepted/Conditionally Accepted/Rejected) | Sort collars by inspection results. |

Sign off (QA Officer and Supplier Representative) | Both sides sign to confirm the check. |

Tip: Use the Card’s AQL and defect rules to help with your inspection and tagging.

Sampling Plan and Defect Taxonomy

You need a sampling plan that follows industry rules. ISO-style AQL sampling tells you how many collars to check and what problems to look for. The table below shows the best levels for small dog collars:

Defect Category | Typical AQL Levels |

|---|---|

Critical Defects | 0% |

Major Defects | 2.5% |

Minor Defects | 4.0% |

Critical defects are things like collars opening by mistake, sharp edges, or broken parts. Major defects are things like slipping, latch wear, or rust. Minor defects are small things like scratches or printing mistakes. Set your sampling plan before you start selling and use it for every batch.

For more help with rules and labels, see StridePaw’s Custom Dog Collars for Wholesalers: Practical Compliance and Labeling Guide.

Test Reports and Traceability

You need good records to show you follow the rules and can track every batch. Keep these records for each shipment:

Test certificates for each product and market

Updated papers that match the latest rules

Records showing where all materials come from

Keep checking as rules change

Chemical reports for all materials

Test reports from trusted labs

Compliance certificates for each market

Material safety data sheets (MSDS) for all parts

Supply chain papers showing material sources

Note: Use the Card’s WL/PL/UT to explain why better hardware costs more. Ask for a quote or samples / get a catalog from StridePaw to compare records and tracking.

A small drop in returns can help you make more money. If you lower returns by 2% on a 1,000-unit order, you keep 20 more sales. Use the Card’s AQL and defect rules to protect your profit.

You can find more safety features in StridePaw’s Collars for Dogs That Prioritize Safety Features…. For more products, visit the StridePaw collar collection page. Want to make your sourcing better? Visit StridePaw Get A Quote.

RFQ Template and Supplier Scorecard

RFQ Essentials for Micro Collars

When you want to buy micro-buckle collars for little dogs, you need a clear RFQ template. This helps you get the right prices and makes sure suppliers know what you want. Always include important specs from the Card like WL, PL, UT, cycle target, AQL, and salt fog hours. These details help keep your collars strong and safe. They also help you get fewer returns.

Tip: Use the Card’s WL/PL/UT to explain why better hardware may cost more. If you lower returns by 2% on 1,000 collars, you keep 20 more sales. This helps you make more money. Use the Card’s AQL and defect rules to protect your profit.

Here is a checklist you can use for your RFQ:

RFQ Checklist for Micro-Buckle Small Dog Collars

1. Target dog weight class (2–10 kg)

2. Working Load (WL), Proof Load (PL), Ultimate Strength (UT) – per Card

3. Buckle type (acetal or metal) and anti-pop-open features

4. D-ring material and corrosion requirement (salt fog hours per Card)

5. Webbing width and thickness, slot/webbing fit

6. Cycle test target (open/close and loaded cycles per Card)

7. Edge-finish acceptance (“no sharp edges/points,” “no burrs,” “no fray”)

8. QC sampling plan (AQL: Critical 0, Major 2.5, Minor 4.0)

9. Required documentation (test reports, batch traceability)

10. Lead time and production capacity

11. Packaging and labeling requirements

12. Request for samples and catalog

Ask for a quote or samples / get a catalog from StridePaw to compare hardware, fit, and safety features.

Supplier Scorecard for Evaluation

You should use a scorecard to check how well each supplier meets your needs. This helps you pick the best partners for your brand. The scorecard below lists the most important things to look for when buying small dog collars.

Criteria | Description |

|---|---|

On-time delivery rate | Shows if the supplier ships orders when promised. |

Defect rate | Tracks how many collars fail to meet specs or have issues. |

Responsiveness to inquiries | Measures how quickly the supplier answers your questions. |

Adherence to specifications | Checks if the supplier follows all your collar specs from the Card. |

Multi-stage inspections | Confirms the supplier uses checks during production, not just at the end. |

Material certification | Requires proof of material quality, especially for eco-friendly claims. |

Detailed material standards | Lists exact requirements for webbing, hardware, and finish. |

Durability (cycle target) | Verifies the buckle passes the Card’s cycle test. |

Slippage control | Ensures no abnormal slippage under PL. |

Corrosion performance | Confirms hardware passes salt fog test per Card. |

Consistency | Checks if batches match in color, size, and finish. |

Lead time | Measures how fast the supplier can deliver your order. |

Communication | Rates how well the supplier keeps you updated. |

You can use this scorecard to rate each supplier after you get samples or orders. This makes it easier to find good partners and avoid problems.

For more safety features, see StridePaw’s Collars for Dogs That Prioritize Safety Features…. To see more products, visit the StridePaw collar collection page.

You can make your buying process better by following these steps: pick your target dog weight class, set WL/PL/UT, choose buckle type, set cycling test, set edge-finish rules, set QC sampling, then start with a pilot order. Ready to get started? Visit StridePaw Get A Quote.

Packaging and Merchandising for Small Dog Collars

Size Run and Planogram Logic

You need to plan your size run before you place an order for miniature dog collars. Start by defining your target dog weight class. Use the Card’s WL, PL, and UT to set your technical requirements. Choose buckle type and edge-finish acceptance based on your market. Set your QC sampling plan using the Card’s AQL. Launch a pilot order to test your planogram.

A clear size run helps you cover the most common neck sizes for little dogs. You can use a simple table to organize your assortment:

Size Label | Neck Circumference Range | Target Dog Weight Class |

|---|---|---|

XS | 18–25 cm | 2–4 kg |

S | 23–32 cm | 4–7 kg |

M | 28–38 cm | 7–10 kg |

You should display all sizes together on your planogram. Place the most popular sizes at eye level. This makes it easy for buyers to find the right fit. Group by color or style to help your team restock quickly.

Tip: Use the Card’s AQL and defect definitions to check every batch before you put collars on the shelf.

Packaging Features to Reduce Returns

You can lower your return rate by choosing the right packaging for miniature dog collars. Clear packaging lets buyers see the collar’s size, color, and hardware. Add a simple size guide on the back. Show how to measure a dog’s neck and use the two-finger rule. Include a checklist of safety features, such as anti-pop-open buckles and smooth edge finishes.

You should add a QR code that links to StridePaw’s Collars for Dogs That Prioritize Safety Features…. This helps buyers learn about safety and fit. Use the Card’s WL/PL/UT to justify cost of better hardware on your packaging. Show buyers why your collars are safer and more reliable.

A small drop in your return rate can boost your gross margin. For example, if you lower returns by 2% on a 1,000-unit order, you keep 20 more sales. Use the Card’s AQL and defect definitions to protect your profit.

Request a quote or ask for samples / get a catalog from StridePaw to compare packaging options and safety features.

You can link your packaging to StridePaw’s collar collection page for more product choices. Ready to improve your merchandising? Visit StridePaw Get A Quote.

You can get safer collars for little dogs by doing these steps. First, pick your target dog weight class. Next, set WL/PL/UT for your collars. Then, choose the buckle type that fits your needs. After that, plan a cycling test for the buckles. Set rules for edge-finish acceptance. Use QC sampling before you place a pilot order. Use tables and checklists to help with supplier talks and quality checks. The Card’s AQL and defect definitions help you check for problems. WL/PL/UT helps you explain why better hardware costs more. If you lower returns by 2% on 1,000 collars, you keep 20 more sales. You can ask for a quote or samples, or get a catalog. See StridePaw’s Collars for Dogs That Prioritize Safety Features or visit the collar collection page. For next steps, try pilot testing, do supplier audits, and keep checking with QC. Visit StridePaw Get A Quote.

FAQ

What is the first step when sourcing collars for little dogs?

You should define your target dog weight class. This helps you set the right WL, PL, and UT from the Card. Start every sourcing project with this step.

How do I justify the cost of better hardware to my team?

Use the Card’s WL/PL/UT to justify cost of better hardware. Stronger hardware lowers escapes and returns. Safer collars protect your brand and reduce long-term costs.

What is the best way to check if a collar meets safety standards?

Set a QC sampling plan using the Card’s AQL and defect definitions. Inspect each batch for sharp edges, slippage, and hardware quality. Always request test reports from your supplier.

How can a small drop in return rate impact my gross margin?

If you lower returns by 2% on a 1,000-unit order, you keep 20 more sales. Use the Card’s AQL and defect definitions to protect your profit.

What should I include in my RFQ for micro-buckle collars?

List your target weight class, WL/PL/UT, buckle type, cycle target, edge-finish acceptance, AQL, and documentation needs. Request a quote or ask for samples / get a catalog from StridePaw.

How do I ensure the buckle will not pop open during use?

Specify anti-pop-open features and require a cycle test at the Card’s cycle target. Ask your supplier to show test results. For more safety features, see StridePaw’s Collars for Dogs That Prioritize Safety Features….

Where can I compare collar options and safety features?

Visit the StridePaw collar collection page to review product options. For direct help, visit StridePaw Get A Quote.