Imagine your dog pulls hard during training outside while wearing a canine pulling harness. If the harness breaks, you could lose control or your dog could get hurt. You need a harness that is strong and lasts a long time. It should not just look good. Pay attention to how the canine pulling harness is built. The load path is important. This is where the pulling force goes through the stitching and hardware. Check the harness often to find small problems early. This helps you stop accidents before they happen. Look at the harness after every hard pull.

When you need the canine pulling harness to last, check the stitching and hardware on the load path. These spots show damage before you see any on the fabric.

Key Takeaways

Inspect your dog’s harness before each use. Look for signs of wear, especially at stress points like stitching and hardware.

Retire the harness immediately if you find any damage. Safety comes first; do not wait for more signs of wear.

Choose a harness that fits your dog well. A snug fit helps distribute pulling force and keeps your dog safe.

Use strong materials like nylon or polyester for durability. These materials resist wear and tear better than others.

Regularly check the load path of the harness. This area carries the most force and is crucial for your dog’s safety.

Durability in Canine Pulling Harness—Focus on Load Path

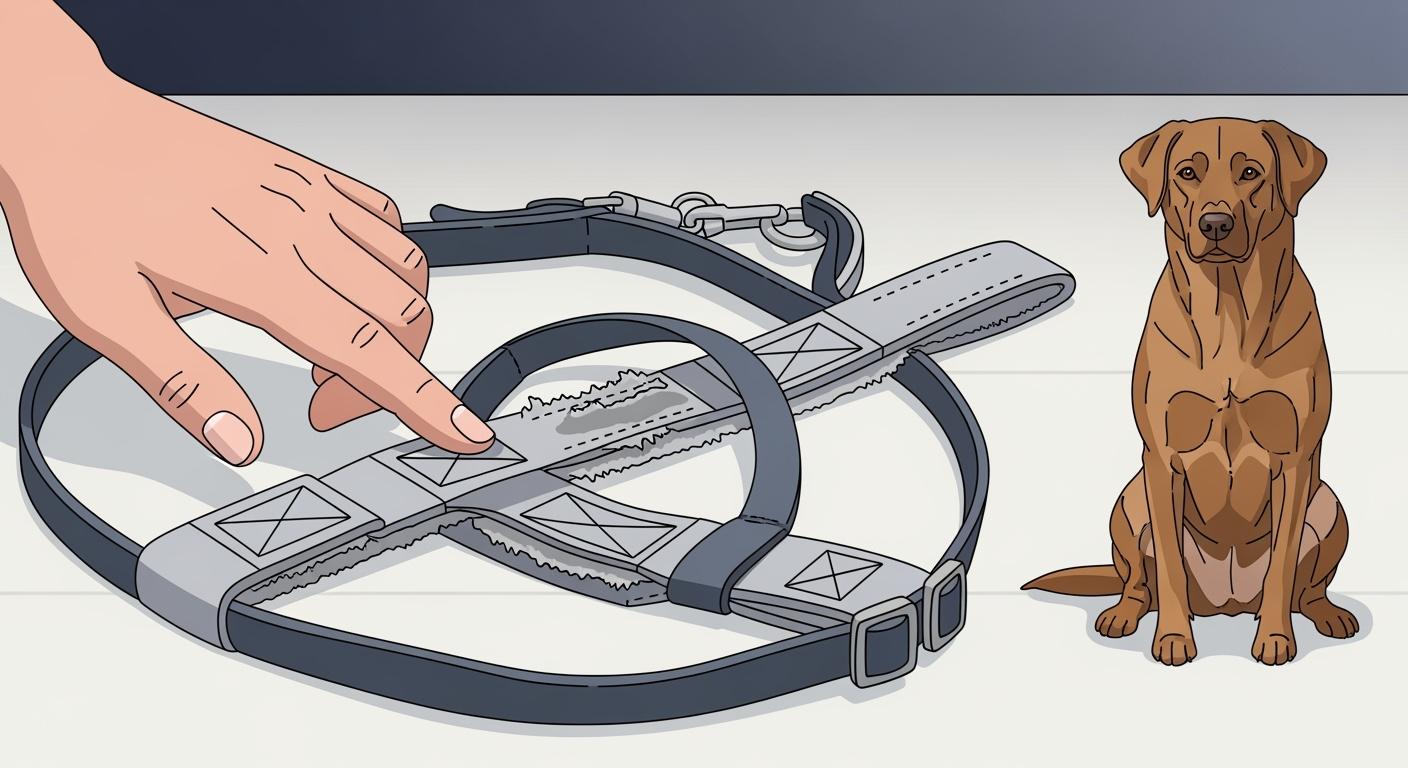

Understanding the Load Path and Stress Points

When you use a canine pulling harness, the load path carries the force from your dog’s movement through the harness. The load path starts at the leash attachment point. It travels through the hardware, stitching, webbing, and finally spreads across the chest and back. Each part along this path must handle high strength and repeated stress.

Stress points are places where the harness bends, folds, or rubs against other surfaces. These spots often show the first signs of wear. You should pay close attention to the stitching near the leash ring, the folds by the adjusters, and the areas under your dog’s armpits. These zones face the most friction and pressure during use.

Tip: Always check the load path after any strong pull. Early signs of damage often appear at stress points before you notice problems elsewhere.

Common Failure Points in Harnesses

Not all parts of a harness fail at the same rate. Some areas wear out faster because they handle more force or friction. Here are the most common failure points you should watch:

Stitching at Attachment Points

The stitching near the leash ring or D-ring takes the most force. Broken or loose threads here can lead to sudden failure.Adjuster Folds

The webbing folds back on itself near adjusters. Repeated movement can thin the webbing or cause it to crack.Friction Zones

The harness rubs under your dog’s armpits and chest. Over time, the webbing may fray, or the edge binding may wear through.Hardware

Metal parts like rings or buckles can develop sharp edges or rust. These can cut the webbing or fail under load.Buckles

Plastic or metal buckles may stop locking properly. Cracks or deformation mean the harness can open unexpectedly.

You should inspect these areas often. If you see any damage, do not use the harness until you fix or replace it.

Here is a comparison table of common harness structures. This table shows which type might suit your needs and where you should expect the most wear:

Option | Best for | Pros | Cons | Notes (Durability & Failure Modes) |

|---|---|---|---|---|

Y-front with rear attachment | Strong pullers | Good force distribution | May shift on slim dogs | Stitching at rear ring and armpit friction are weak points |

Multi-point adjustable | Growing or varied breeds | Custom fit, flexible sizing | More adjusters to check | Adjuster folds and hardware prone to abrasion and cutting |

Minimal webbing | Light, short activities | Lightweight, less bulk | Less padding, less support | Webbing edges and buckles wear quickly, less abrasion resistance |

Padded panel with reinforced zones | Long pulls, sensitive skin | Extra comfort, strong reinforcements | Heavier, slower drying | Reinforced zones resist wear, but edge binding can fray |

Safety Boundaries—Retire-Now Rules for Harness Damage

You must always put safety first. If you find any damage along the load path, retire the harness right away. Do not wait for more signs or try to repair it for further use. Here are the main reasons to retire a harness immediately:

The harness has stopped a fall or taken a heavy impact.

You see cuts, burns, deep abrasions, or signs of chemical or sun damage.

Hardware shows cracks, rust, bending, or does not work smoothly.

Stitching is broken, pulled out, or looks uneven.

Labels are missing or you cannot read them.

The harness has reached the end of its recommended service life.

Safety note: Any damage to the load path means you should stop using the harness. Replace it to keep your dog safe.

Durability depends on regular checks and knowing when to retire your gear. You protect your dog best when you act early and follow these safety boundaries.

Durable Features—Materials and Construction for Best Dog Harness

Webbing Choices and Durability (Nylon, Polyester, Coated)

You want your best dog harness to last a long time. The webbing material is very important for how strong it is. Nylon webbing can handle strong pulls and does not wear out fast. Polyester webbing is even better for outdoor use. It protects well from the sun and rubbing. Coated webbing keeps out water and dirt. But you should also check if it is soft and bends easily. Here is a table to help you compare:

Material | UV Resistance | Abrasion Resistance | Longevity |

|---|---|---|---|

Polyester | Superior | Superior | High |

Nylon | Moderate | Moderate | Good |

Coated Webbing | Varies | Varies | High |

If your harness has many places to adjust, pick webbing that does not fray or get thin. This keeps the handle strong and safe for your dog.

Reinforcement Methods—Box-X, Bartack, Edge Binding

Strong stitching helps your best dog harness stay safe. Box-X and bartack stitches make the handle and leash ring stronger. Bartack uses a zigzag stitch so threads do not come loose. Edge binding covers the sides of the webbing. This stops the edges from wearing out, especially near the adjusters and under the padded chest. You should look at these strong stitches often, especially after your dog pulls hard. Owner tip: After a hard pull, check the stitching and folds right away.

Hardware and Buckle Selection for Long-Lasting Harnesses

Good hardware and buckles help your best dog harness last longer. Metal rings and buckles should feel smooth and not have sharp spots. Plastic buckles must snap shut and open easily. Many adjustment points let you fit the harness to your dog’s body. This also makes the handle easy to hold. If you see cracks, rust, or loose parts, get a new harness right away. Pick hardware that is as strong as the webbing and supports the padded chest for comfort.

A harness with strong features, a good handle, and many adjustment points helps you feel safe. You protect your dog best when you check the padded chest, comfort parts, and all adjusters often.

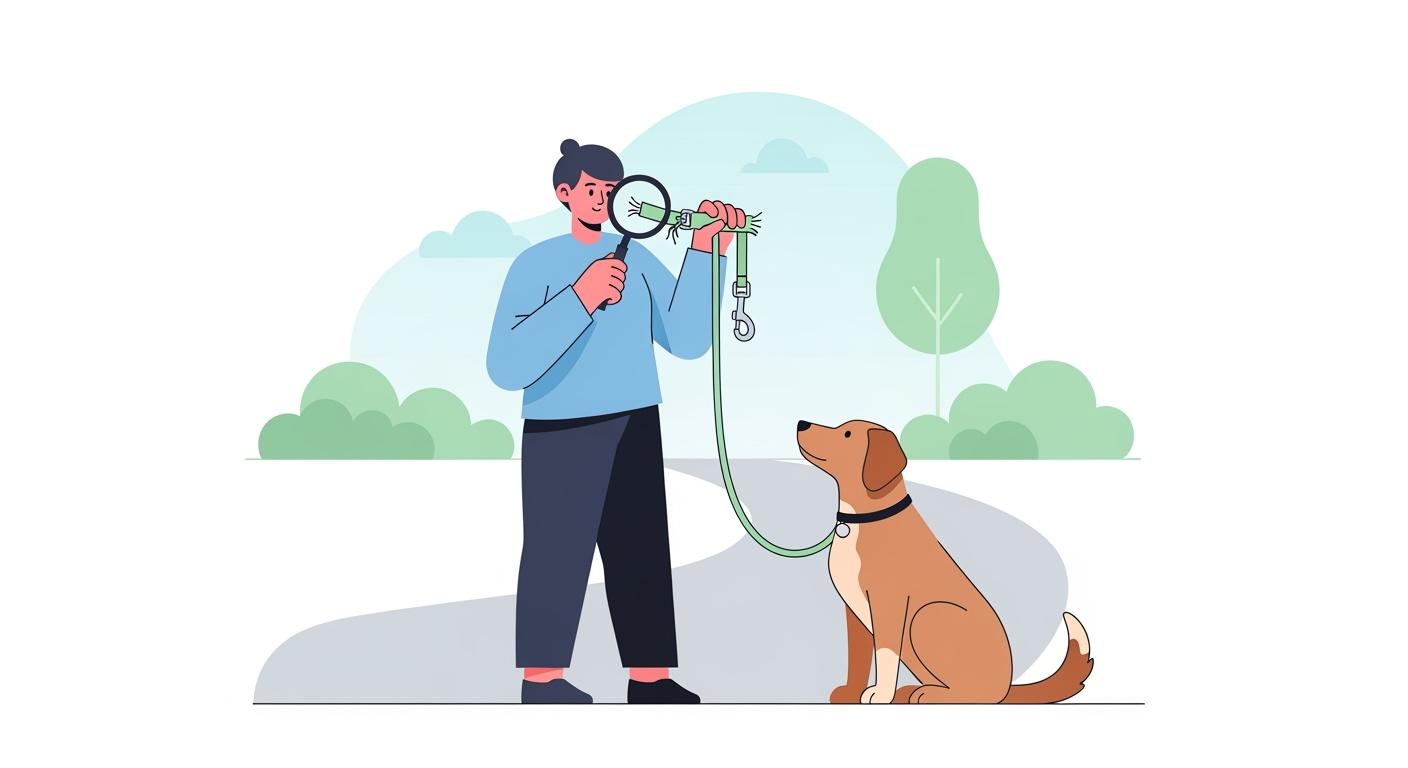

Harness Inspection—Step-by-Step Durability Check

Identify Key Load Path and Stress Points

You need to find where the harness gets the most force. The load path starts at the leash attachment. It goes through the hardware, stitching, and webbing. Stress points are places where the harness bends or rubs your dog. These spots are near the leash ring, by the adjusters, and under the armpits. Focus your inspection on these areas because they wear out first.

Tip: After a strong pull or quick movement, check the stitching and folds near the adjusters right away. This helps you find problems before they get worse.

Inspect Stitching, Reinforcements, and Webbing

Look closely at all the stitching along the load path. Check for broken threads, loose ends, or thin shiny stitches. Reinforced spots like box-X or bartack stitches should cover stress points and stay flat. Look at the webbing for cuts, deep scrapes, or thin spots. If you see fraying, hard spots, or any damage, the harness may not be safe.

Use this checklist for a quick inspection:

Check all stitching for breaks, loose threads, or uneven lines.

Look at reinforced spots to make sure they are still attached and not peeling.

Run your fingers along the webbing to feel for cuts, thin spots, or rough places.

Check the edges for fraying or hard spots, especially near adjusters and under the chest.

Check Adjusters, Hardware, and Buckles

Check every adjuster, buckle, and piece of hardware before each use. Make sure adjusters hold the webbing tight and do not slip. Look for white marks, cracks, or folds near the adjusters. Metal parts should feel smooth and not have sharp edges or rust. Buckles must snap shut and open easily. If a buckle does not lock or feels loose, do not use the harness.

Here is a simple list to help your inspection:

Check all buckles for cracks, bent spots, or locking problems.

Look at hardware for rust, sharp edges, or bending.

Test adjusters to see if they grip the webbing and do not slip.

Make sure all parts move smoothly and do not make strange sounds.

Follow these steps before every use. For formal checks, inspect the harness at least every six months. Remove the harness after any hard pulling event.

Inspection Requirement | Frequency |

|---|---|

Pre-use inspections | Before each use |

Formal documented inspections | Every 6–12 months |

Removal from service | After high-force events |

Pass/Fail Criteria and Retire-Now Actions

Use a clear pass/fail system for safety. If any part fails, stop using the harness right away. Do not try to fix or keep using it. The table below shows when to retire a harness:

Pass/Fail Criteria for Harness Inspection | Actions if Harness Fails |

|---|---|

Harness has stopped a fall or taken a heavy impact | Remove from service |

Cuts, burns, abrasion, chemical, or UV damage found | Remove from service |

Hardware shows cracks, rust, or does not work properly | Remove from service |

Stitching is broken, pulled, or looks uneven | Remove from service |

Labels are missing or cannot be read | Remove from service |

Manufacturer’s service life has expired | Remove from service |

Any sign of defects, damage, or deterioration | Remove from service |

Most harness makers say the harness should last five years from first use. Check the harness before each use and do a full inspection once a year. The age of the harness does not always mean it is unsafe. If you keep it clean and check it often, it may last longer. Always follow the manufacturer’s instructions and remove any harness that shows damage.

Owner note: After a strong pull, check the stitching and folds near the adjusters right away. Do not wait for damage to get worse.

Careful inspection keeps your canine pulling harness safe and strong. You protect your dog and control pulling better when you act early and retire damaged gear.

Fit, Not a Fit, and Alternatives for Durable Harness Use

Fit—When a Canine Pulling Harness Is the Best Choice

You should choose a canine pulling harness when you want reliable pulling control and a secure fit for your dog. A proper fit means the harness matches your dog’s chest, neck, and body shape. This helps spread force across the chest and shoulders, reducing strain on the neck. You get the best results when you check the harness often and adjust it for a snug fit. Dogs that pull hard, have unique builds, or need extra support benefit most from a large dog harness or an escape-proof harness.

Harness Type | Suitable For |

|---|---|

No Pull Dual-Clip Harness | Strong Pullers |

Robust Y-Harness | Occasional Pullers |

Adjustable Y or H harnesses | Unusual Builds |

Voyager Step-In Air Harness | Tiny/Sensitive Dogs |

A snug fit and secure hardware help prevent escapes and keep your dog safe during outdoor activities. You should always look for reinforced webbing, strong buckles, and breathable padding.

Match the harness to your dog’s size and behavior.

Use a harness with a secure fit for dogs that pull or need extra support.

Adjust the straps for a snug fit every time you use it.

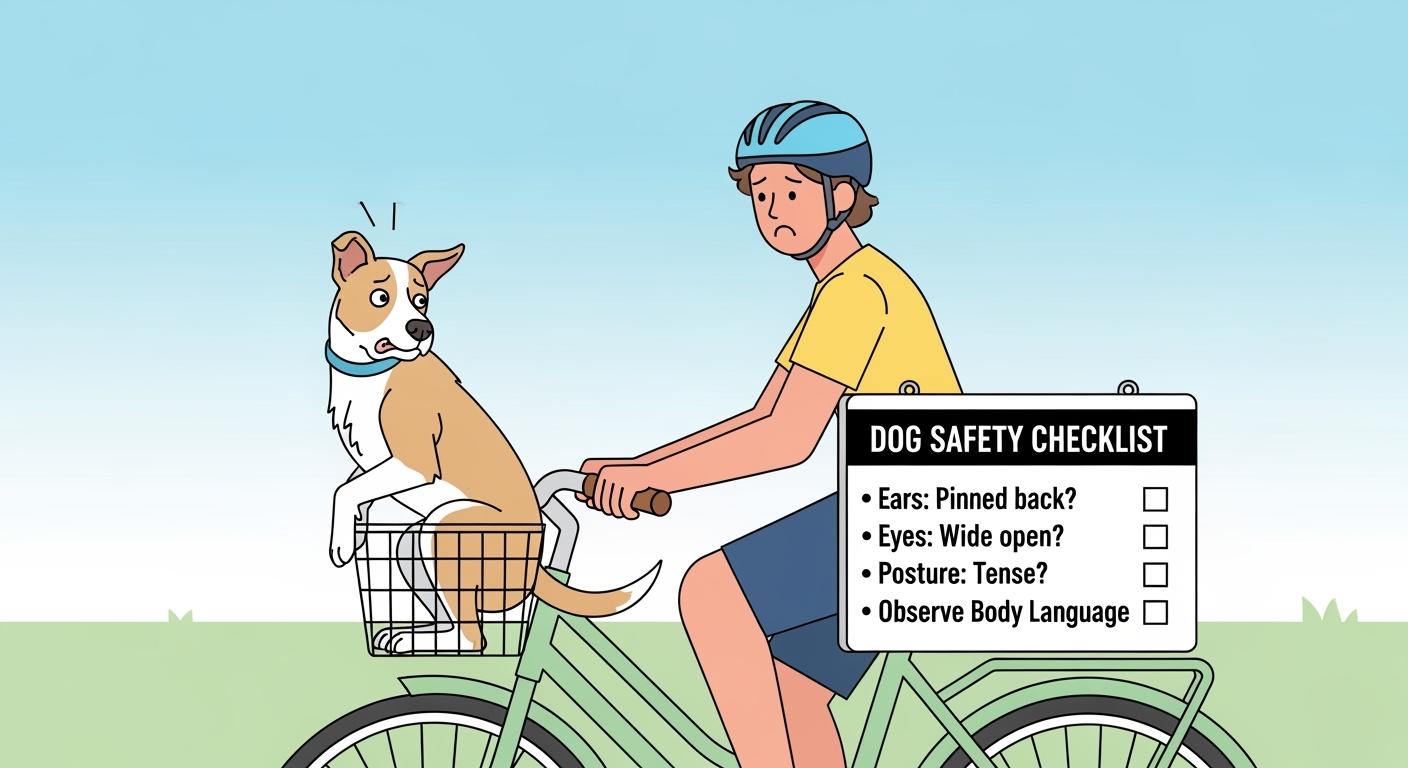

Not a Fit—Red Flags and High-Risk Scenarios

Some situations make a harness unsafe or less effective. Watch for these red flags:

Your dog chews on straps or stitching.

You cannot clean or dry the harness after saltwater or mud exposure.

Your dog lunges or pulls constantly without supervision.

The harness does not stay in place or you cannot achieve an escape-resistant fit.

Your dog shows anxiety, fear, or refuses to move when wearing the harness.

If you see these signs, the harness may not provide a secure fit or proper support. You should stop using it and look for other options.

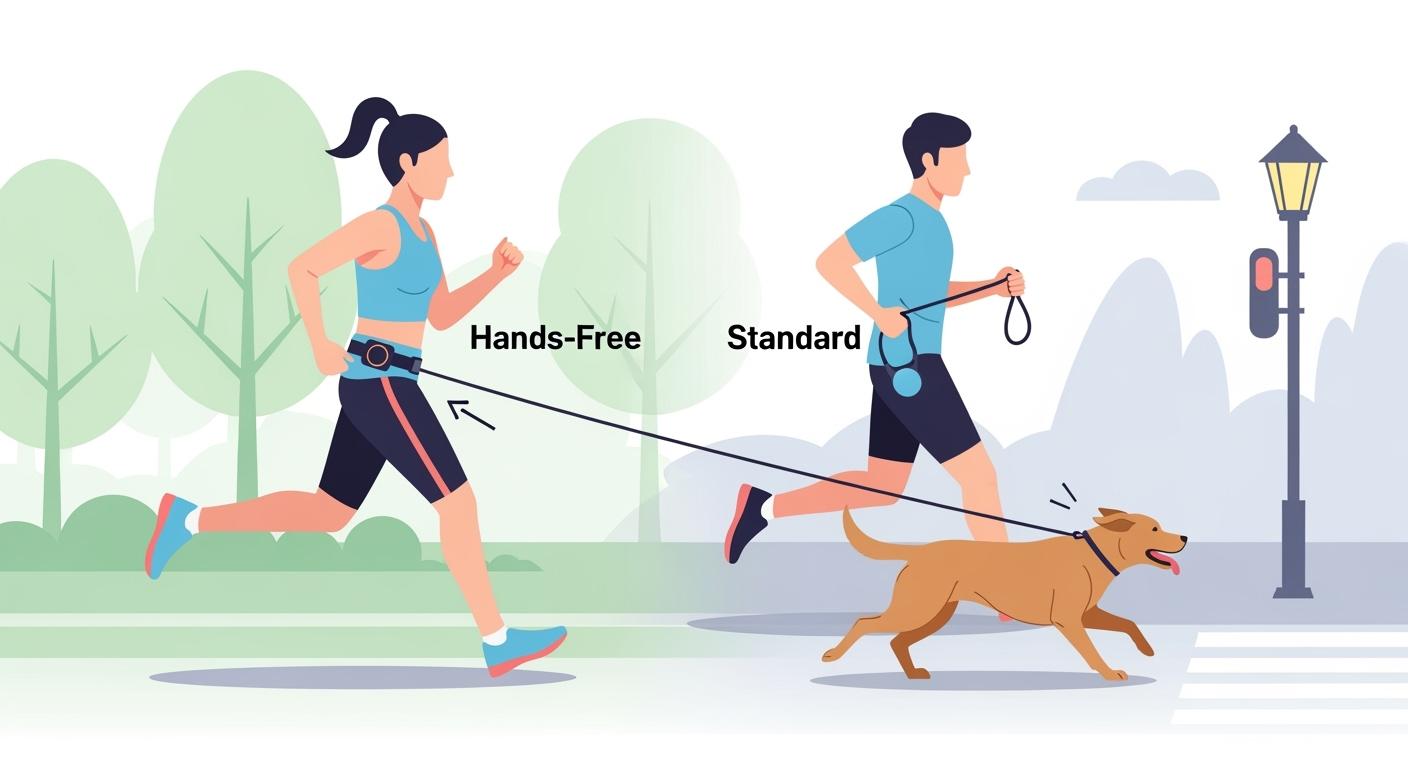

Alternatives—Safer Structures and Training Adjustments

You can try different solutions if a standard harness does not work for your dog:

Choose a harness with closed edges or extra padding to reduce chewing and wear.

Use a double connection system for more pulling control and an escape-resistant fit.

Train your dog to walk calmly and reduce sudden pulls. This lowers stress on the harness and improves safety.

Tip: A snug fit and regular checks help you spot problems early and keep your dog safe.

Next Steps—Contact, Sample, and Support Options

If you want to test a harness before buying, you can request a free sample for evaluation. You can also ask for technical support or a custom design to match your needs. Many suppliers offer engineering support to help you choose the right harness and ensure a secure fit.

Service Type | Description |

|---|---|

Free Sample | Request a sample to check fit and durability before purchase. |

Engineering Support | Get help with custom designs or technical questions. |

You can contact the supplier for a quote, a spec sheet, or more information about escape-proof harness options. This helps you make the best choice for your dog’s safety and comfort.

You keep your dog safe when you choose a canine pulling harness with strong materials and reliable construction. Focus on the load path and inspect the harness often. Use this checklist to maintain durability and safety:

Inspect for wear and tear before each use.

Clean the harness with mild soap and water.

Store the harness in a cool, dry place.

Replace any part that shows damage.

You can ask suppliers for test reports and photos of key features. Request a sample or technical support if you need help choosing the right harness.

FAQ

How often should you check your canine pulling harness?

You should check your harness before every use. Look for damage after any strong pull. Regular checks help you spot problems early and keep your dog safe.

What is the load path on a harness?

The load path is the route the pulling force takes through the harness. It starts at the leash ring, goes through the stitching and webbing, and spreads across your dog’s chest and back.

When should you replace a harness?

Replace your harness if you see broken stitching, cuts in the webbing, bent hardware, or buckles that do not lock. Do not wait for more damage.

Can you wash a canine pulling harness?

Yes, you can wash most harnesses with mild soap and water. Rinse well and let it dry completely before using it again.

What should you do after your dog pulls very hard?

Tip: Check the stitching and adjuster folds right away. Look for loose threads or thin spots. Replace the harness if you find any damage.