For big dogs, harnesses can break if stitching or hardware fails. Sometimes, the load paths also break. These issues can cause safety problems and returns. You need a big harness for dog that keeps your dog safe. It should also be comfortable. Pay attention to webbing, stitching, and hardware when you choose a harness. The harness should fit your dog well. It should also stop your dog from escaping. Look for harnesses with dual-clip and no-pull features. These features help with safety and comfort. An escape-proof harness uses strong materials. It also fits in a way that stops escapes. The best harnesses follow standards like ASTM and ISO. These standards help with durability and safety. Check if the harness is stronger at stress points.

Safety Standard | Application |

|---|---|

ASTM D2347 | Load Testing |

ISO 811 | Water Resistance Simulation |

ISO 13934-1 | Durability Testing |

ASTM D543 | Material Composition |

ASTM F2992 | Escape Resistance |

ASTM F1927 | Reflective Technology |

ISO 10319 | Pull Control |

Key Takeaways

Pick harnesses that have strong webbing and extra stitching. This helps the harness last longer and keeps big dogs safe. – Find harnesses with two clips and no-pull features. These help you control your dog and stop escapes. – Check the hardware closely. Metal parts are usually stronger and work better than plastic ones. – Look at the stress points often for damage or wear. This helps stop breaks and keeps your dog safe. – Ask suppliers for test reports. These reports show if harnesses meet safety rules like ASTM and ISO.

What makes a big harness for dog strong and safe

Real-world forces: pulling, lunging, lifting

You face many challenges when you select a large dog harness. Big dogs can pull hard, lunge suddenly, or need lifting support. These actions put a lot of force on the harness. Laboratory tests show that harnesses must handle strong pulling control. Researchers used a leash tension meter to measure pulling force in shelter dogs. They found that chest harnesses help control pulling better than neck collars. Some harnesses, like the Balance harness, improve control during lunging. You need a harness that can stand up to these real-world forces every day.

When you look for a big harness for dog, think about how your dog moves. Pulling and lunging create sudden stress. Lifting a large dog adds even more load. The harness must spread this force across strong webbing and secure stitching. If any part fails, your dog’s safety is at risk. You want a harness that keeps its shape and strength, even after many uses.

System strength: load path and reinforced junctions

Strength does not come from one thick strap. You get real strength from a harness with a continuous load path and reinforced junctions. The load path means the way force travels through the harness when your dog pulls or lunges. Each junction, where straps meet or hardware attaches, must be reinforced. If you use weak stitching or poor hardware, the harness can break at these points.

The story of Max, a 78-pound Labrador Retriever, shows why reinforced junctions matter. Max switched to a front-clip large dog harness with triple-stitched junctions and high-quality materials. After 18 months of heavy use, the harness showed very little wear. Reinforced stitching and durable materials can make a harness last much longer for big dogs.

You can follow a step-by-step buyer structure to make sure you choose a strong and safe harness:

Define your target large-dog use cases and highest-load scenarios. Think about pulling, lunging, and lifting.

Map the load path and identify high-stress junctions. Focus on where straps meet and hardware connects.

Specify webbing, fabric, padding, and edge finishing for both strength and comfort.

Specify hardware and adjusters as the bottleneck control. Make sure they match the strength of the webbing and stitching.

Specify test methods to validate build strength and durability. Use ASTM D6775 for webbing breaking strength, ASTM D1683 for seam strength, and ISO 9227 for metal corrosion resistance.

Set QC gates for pilot orders, incoming inspection, and in-line checks.

Launch a small pilot, review failure modes, then lock the spec for full production.

Tip: Always ask your supplier for test reports that show the harness meets ASTM and ISO standards. This helps you avoid weak points and ensures long-term safety.

A strong large dog harness uses matched materials, reinforced stitching, and reliable hardware. You get better pulling control and longer product life when you follow these steps.

Mapping load paths for best dog harness for large dogs

Force zones: chest, sternum, girth, back

When you pick a harness for a big dog, you need to know how force moves through it. The chest, sternum, girth, and back are the main force zones. Each spot handles different stress when your dog pulls or moves fast. The chest and sternum take most of the forward force. The girth keeps the harness in place. The back helps spread weight and controls movement.

A harness that spreads force over these zones lowers injury risk and makes your dog more comfortable. Look for harnesses without sharp edges or stiff spots at pressure points. Padding and smooth webbing edges stop chafing and discomfort, especially on long walks or during play.

Stress points: bar-tacks, D-rings, adjusters

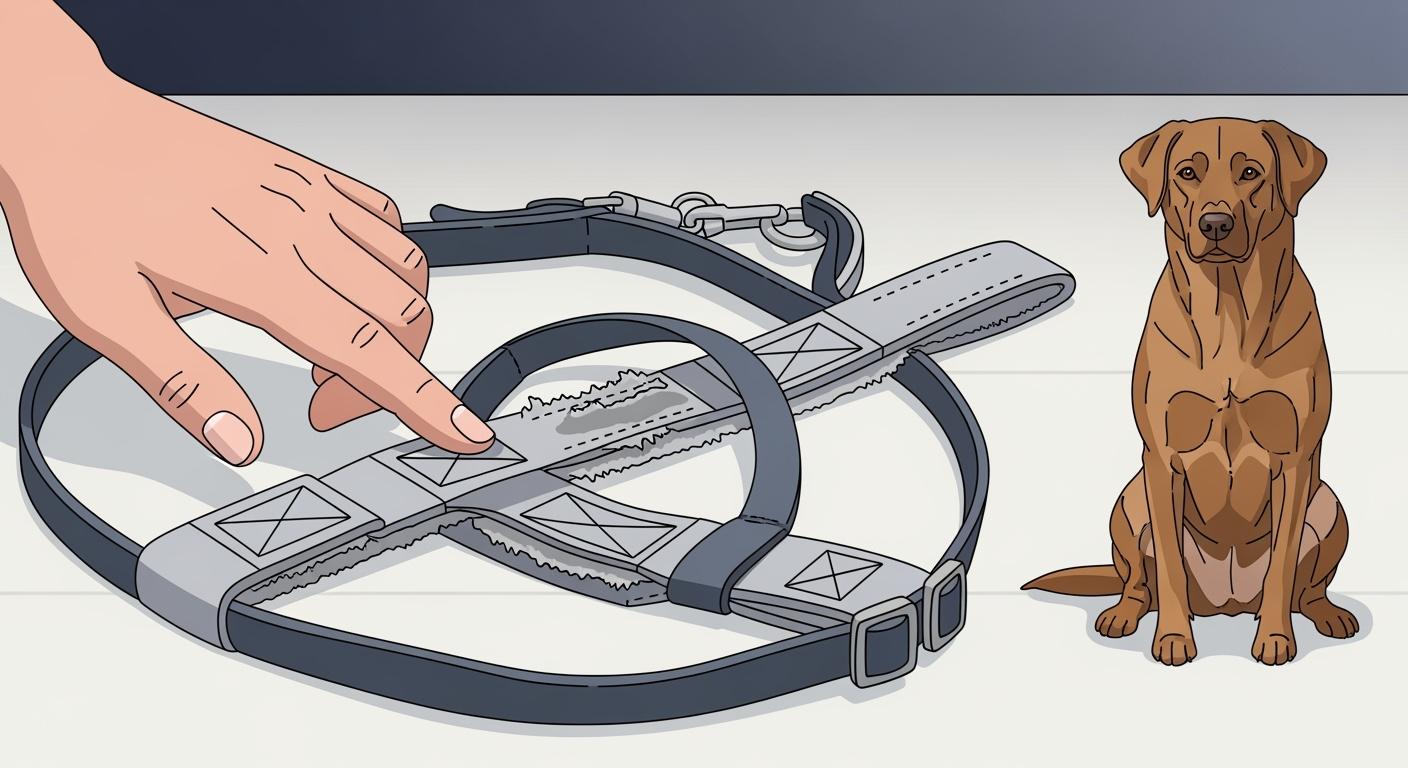

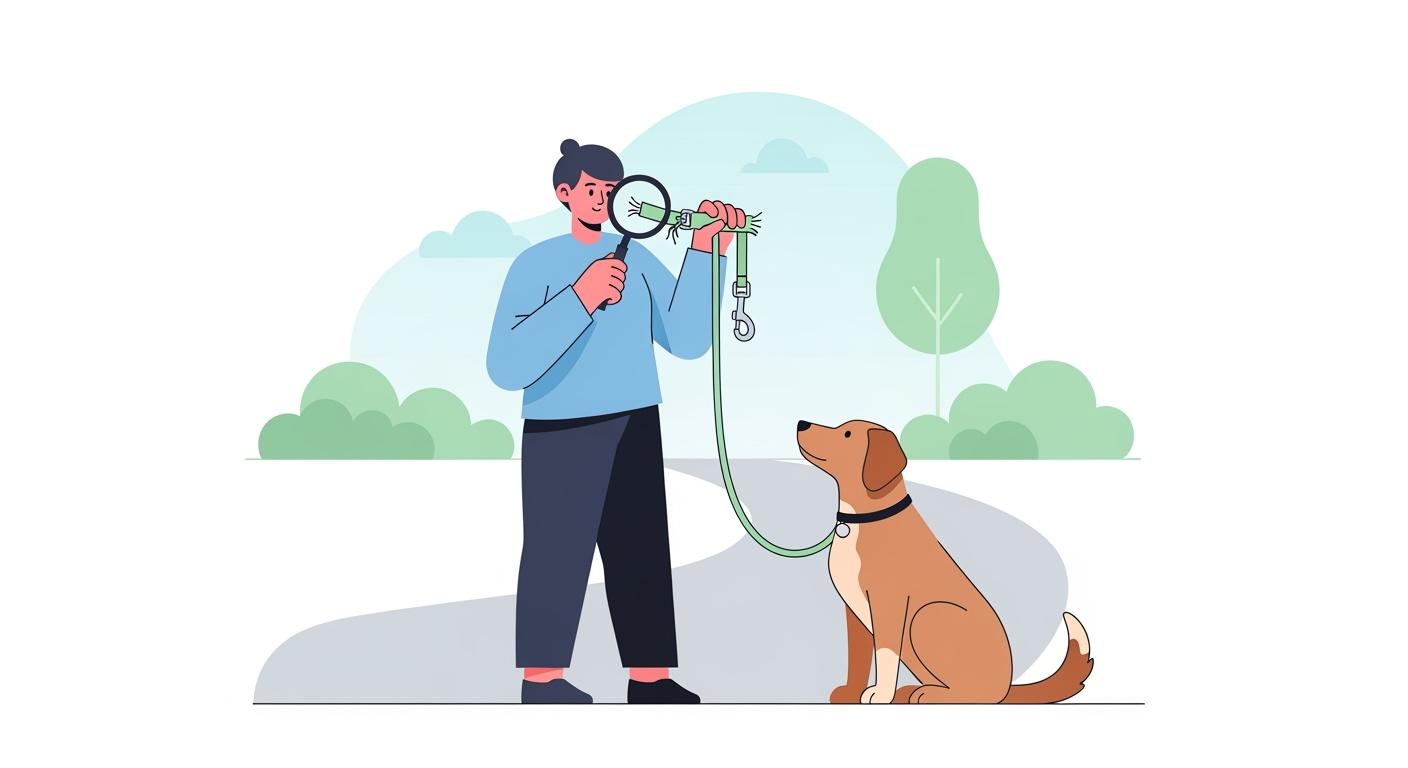

Stress points are where harnesses break most often. You should check bar-tacks, D-rings, and adjusters carefully. These parts hold the harness together when your dog pulls.

Common signs of wear include:

Fraying and scrapes on the webbing near D-rings or straps. Worn fibers make the harness weaker and less able to handle force.

Broken stitching, like loose or missing threads. Weak stitching can make the harness fall apart at rings and buckles.

Rusty or stiff hardware. Orange rust or rough movement in buckles, D-rings, or adjusters means the metal is getting weak and could break.

Tip: Check these stress points often. Finding wear early helps stop sudden breaks and keeps your dog safe.

A strong harness uses tough bar-tacks, rust-proof hardware, and tight adjusters. Ask your supplier for test reports that show the harness meets ASTM and ISO standards. This helps you avoid returns and makes sure the harness lasts a long time.

Materials for durability and comfort

Picking the right harness materials is very important. It helps make a big harness for dog strong and comfy. Each part of the harness must work well together. Good harness materials give strength, a nice fit, and last a long time. You want your harness to keep your dog safe and happy, even after many walks.

Webbing: nylon vs polyester, thickness, edge profile

Webbing is the main part of the harness. You need webbing that is strong and fits well. Nylon and polyester are the most used harness materials. Each one has its own good points.

Here is a table to help you pick:

Material | Tensile Strength | Abrasion Resistance | UV Resistance |

|---|---|---|---|

Nylon | Very High | Excellent | Moderate |

Polyester | Moderate to High | Lower than Nylon | Excellent |

Nylon webbing is very strong and does not wear out fast. It works well if your dog pulls or runs a lot. Polyester webbing is also strong and does better in sunlight. This is good if you are outside a lot. You should also look at how thick the webbing is. Thicker webbing can take more force but should not feel hard or rough. Edges that are round or covered help stop rubbing and make it more comfy. Always check that the webbing sits flat on your dog.

Padding and lining: abrasion resistance, fit, breathability

Padding and lining make the harness softer and safer. These parts should not wear out fast and should fit your dog’s body. Soft padding spreads out pressure and stops sore spots. The lining should let air move through to keep your dog cool and dry. Good airflow stops heat and skin problems.

A good fit means the padding stays flat on the chest and around the body. It should not bunch up or twist. Look for harnesses with linings that stay smooth after washing. This keeps the harness nice and safe for daily use. Padding that does not wear out helps your harness last longer.

Foam and shell: compression set, anti-chafe edges

Foam and shell layers help with comfort and fit. The foam should spring back after being pressed. This means it does not stay flat. If the foam gets flat, the harness will not fit right. The shell covers the foam and makes the harness stronger. Edges that stop rubbing help keep your dog’s skin safe.

Check that the foam and shell match the rest of the harness. A good fit means the harness stays in place and does not pinch. All the harness materials should work together for comfort and safety.

Note: OEM means a company makes products from your design. ODM means a company designs and makes products you can sell as your own brand.

When you pick the best harness materials, you get a harness that fits well, feels good, and lasts a long time. Always ask your supplier for details about the materials and test reports. This helps you make sure your harness is safe and high quality.

Stitching and seam safety for big harnesses

Reinforced stitch patterns and thread choices

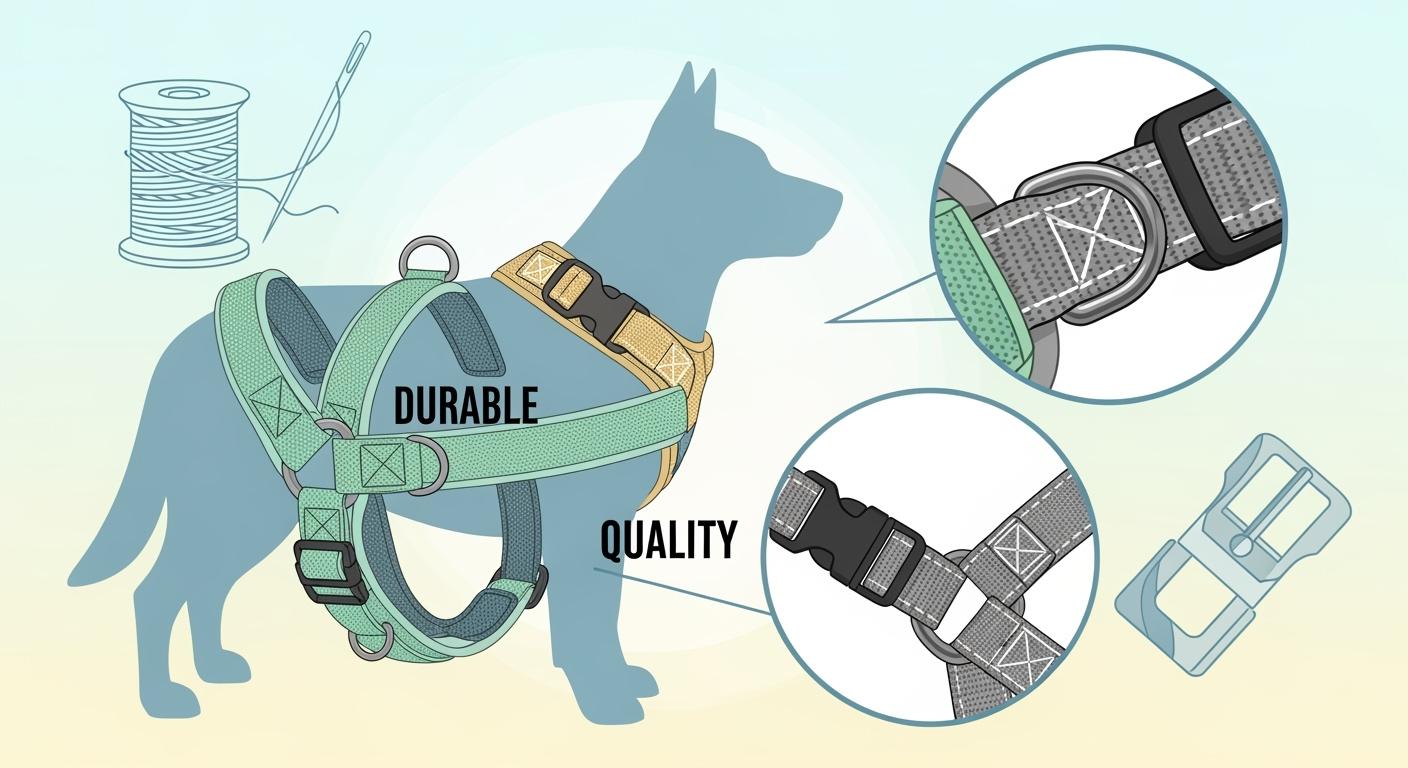

You need strong stitching to keep a harness safe for big dogs. The right stitch pattern and thread choice help prevent breaks at stress points. When you look at top harnesses, you often see box-X and bar-tack stitching. These patterns spread force across a wider area, so one spot does not take all the stress.

Box-X stitching at stress points helps stop single-point failures.

Reinforced bar-tack stitches at every connection point add extra strength.

Bound edges resist fraying, even after heavy use.

You should also check the thread material. Heavy-duty nylon thread works well for harnesses used by working or active dogs. This thread resists UV rays and keeps its strength over time. Good thread helps the harness stay safe and functional, even when your dog pulls hard.

Feature | Details |

|---|---|

Fabric | 1680D ballistic nylon or Cordura® |

Stitching | Bar-tack + X-pattern reinforcement |

Hardware | Stainless steel D-rings (anti-rust) |

Pull Strength | 400–1000 N |

Seam strength: ASTM D1683 testing

You want to make sure every seam in the harness can handle real-world use. ASTM D1683 is a test that checks how much force a sewn seam can take before it fails. This test helps you know if the harness will hold up when your dog pulls, lunges, or moves fast.

Ask your supplier for test reports that show the harness passed ASTM D1683. This gives you proof that the seams will not break under normal use. When you choose a harness with tested seams and reinforced stitching, you help ensure both safety and durability for large dogs.

Hardware reliability for large dog harnesses

Buckles, D-rings, adjusters: metal vs plastic

You need to check the hardware on every harness you consider for large dogs. Buckles, D-rings, and adjusters hold the harness together and take the most force when your dog pulls. Metal hardware often gives you more strength and lasts longer than plastic. Stainless steel and zinc alloy resist bending and breaking. You can use plastic hardware for light-duty or low-stress areas, but it may crack under heavy loads.

When you compare metal and plastic, look for these points:

Hardware Type | Strength | Weight | Common Use |

|---|---|---|---|

Stainless Steel | High | Medium | D-rings, buckles |

Zinc Alloy | Medium | Medium | Adjusters, D-rings |

Acetal Plastic | Low to Medium | Light | Side buckles, adjusters |

You should match the hardware to the webbing and stitching strength. If one part is weak, the whole harness can fail. Always inspect for sharp edges or rough spots that could damage the webbing or hurt your dog.

Corrosion resistance: ISO 9227 salt spray test

You want hardware that stands up to rain, sweat, and outdoor use. Corrosion can weaken metal parts and cause them to fail. The ISO 9227 salt spray test checks how well hardware resists rust and corrosion. In this test, hardware sits in a salt fog made from a 5 percent salt solution for a set time. After the test, you check for binding, loss of strength, or surface damage.

The ISO 9227 test shows if D-rings, buckles, and adjusters will last in wet or salty conditions.

You should ask your supplier for test results on all hardware.

Hardware that passes this test helps improve the durability of your harness.

You can trust a harness more when you know the hardware has passed real-world corrosion tests. This step helps you avoid early failures and keeps your dog safe.

Design features for durability, safety, and fit

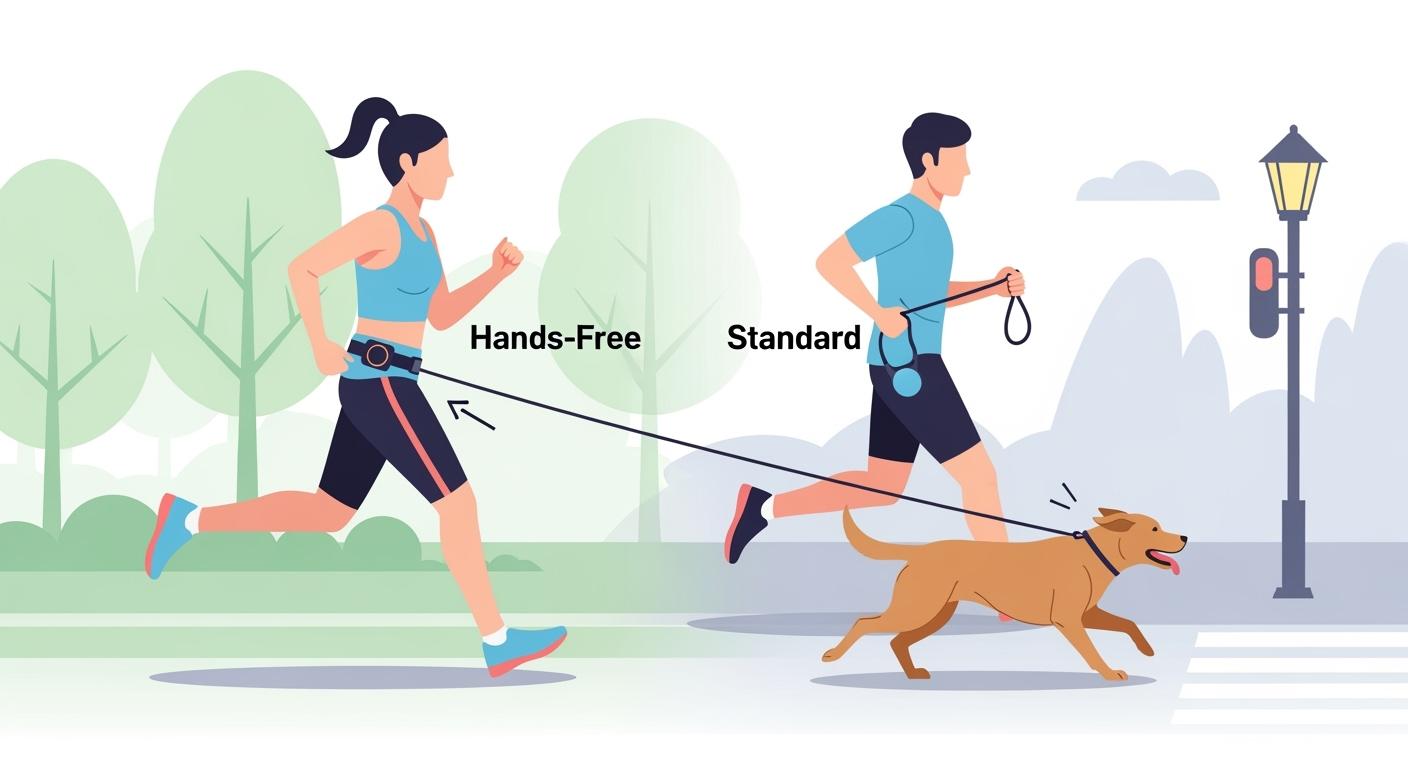

Dual-clip, no-pull, and adjustable straps

You need a harness that helps you control your dog. Dual-clip designs let you put the leash on the front or back. This gives you choices for walking or training. No-pull features help guide your dog gently. They make it easier to stop sudden lunges. You get more control and can keep your dog from escaping.

Big dogs need harnesses with many adjustment points. You can change the fit at the neck, chest, and girth. This helps the harness match your dog’s body shape. When you adjust these spots, you lower the chance your dog slips out. You also make the harness more comfortable. The harness stays secure when your dog moves or pulls.

Here is what experts and studies found about these features:

Study Year | Findings | Implications for Harness Design |

|---|---|---|

2016 | Harnesses change stride length and joint movement, but real-world tests were missing. | Shows harnesses need practical testing. |

2018 | Restrictive harnesses limit shoulder movement, especially in active dogs. | Non-restrictive designs help dogs move better. |

N/A | AKC says harnesses are safer than collars for dogs that pull. | Good fit is important for safety. |

Look for harnesses with dual-clip options, no-pull features, and many adjustment points. These features help you control your dog, stop escapes, and keep your dog safe.

Handle design and anti-chafe finishing

Handles help you guide and control your dog. You need a strong handle for busy places or training. A reinforced top handle lets you grab your dog quickly. This helps you keep your dog safe.

Anti-chafe finishing protects your dog’s skin. Soft, padded straps and smooth edges stop rubbing. You want a harness with adjustable neck and chest straps made from tough woven nylon. This helps you get a good fit and lowers escape risk.

The table below shows how these features work together:

Feature | Description |

|---|---|

Handle Design | Strong top handle gives quick control in busy places or training. |

Anti-Chafe Finishing | Adjustable neck and chest straps made of soft, tough woven nylon for a comfy, chafe-free fit. |

Material | Breathable NeoCool neoprene and soft padded air mesh for comfort. |

Shock Absorption | Padded breastplate absorbs shock during pulling or bite work. |

You get better control and comfort with a harness that has a strong handle and anti-chafe finishing. These features help keep your dog safe and make the harness last longer.

Testing and buyer checks for best dog harness for large dogs

Webbing strength: ASTM D6775

You need webbing that can hold a big dog’s force. Heavy-duty flat nylon webbing is very strong. It can break at up to 8,000 lbs per inch wide. This webbing keeps most of its strength after many uses. Ask your supplier for ASTM D6775 test results. This test shows if the webbing is safe for strong dogs.

Abrasion: ASTM D4966, lightfastness: ISO 105-B02

Rubbing can wear out the harness over time. The ASTM D4966 test checks how well fabric stands up to rubbing. You should also ask about ISO 105-B02 lightfastness. This test shows if the harness keeps its color in sunlight. Both tests help you pick a harness that looks good and lasts longer.

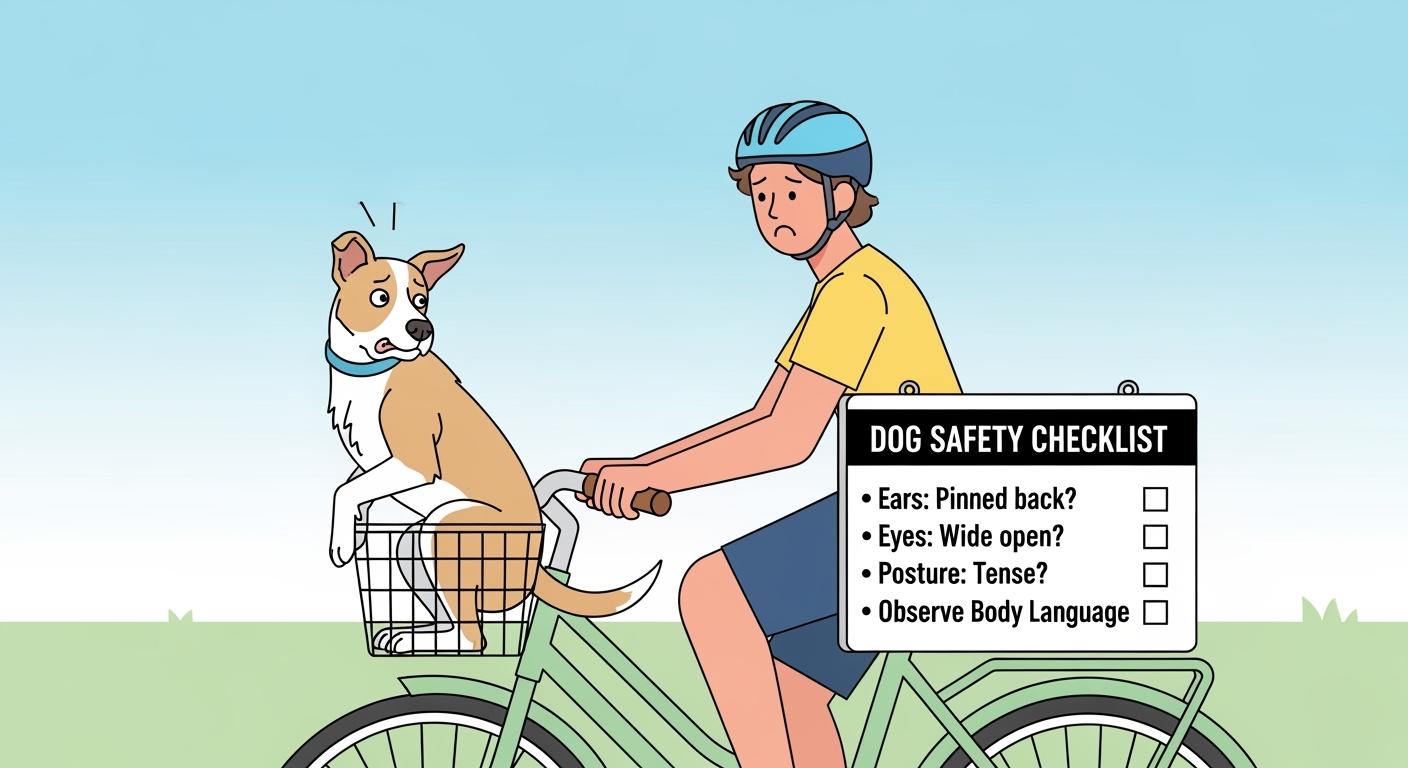

QC: visual and functional inspection

You should check harnesses when you get them. Look for bright color, tight stitching, and soft padding. Check metal D-rings for rust and smooth edges. Review hidden things like color staying bright and hardware type. Use the table below to help with your inspection.

Visual Quality Criteria | Hidden Quality Criteria |

|---|---|

Attractive color and fabric | Fabric colorfastness (resists fading in the sun) |

Metal D-rings | Hardware material and rust resistance |

Looks securely sewn | Stitching strength and thread quality |

Padded for comfort | Padding material and durability |

Table 1: Failure symptom | Likely root cause | Spec or test that prevents it

Buyer symptom | Likely root cause | Spec or test to prevent it |

|---|---|---|

Stitching breaks | Weak thread or poor seam | ASTM D1683 seam strength |

D-ring bends or rusts | Low-grade metal | ISO 9227 salt spray test |

Webbing frays | Low abrasion resistance | ASTM D4966 abrasion test |

Color fades quickly | Poor lightfastness | ISO 105-B02 lightfastness test |

Padding flattens fast | Low-quality foam | Compression set and durability QC |

Table 2: Requirement | What to ask the supplier for | How to verify at receiving

Requirement | What to ask the supplier for | How to verify at receiving |

|---|---|---|

Webbing strength | ASTM D6775 test report | Check for test certificate |

Seam durability | ASTM D1683 test report | Inspect stitching and report |

Hardware corrosion | ISO 9227 salt spray test result | Inspect hardware for rust |

Fabric abrasion resistance | ASTM D4966 test report | Check for smooth, unworn fabric |

Colorfastness | ISO 105-B02 test report | Compare color to approved sample |

Padding durability | Material spec sheet | Press padding, check for rebound |

You can follow these steps and use the tables to help your team pick the best harness for big dogs. Always ask for supplier papers and test reports. Check harnesses closely when they arrive to make sure they are safe and high quality.

Compliance and labeling for safety

US/EU/UK product safety regulations

You have to follow safety rules for large dog harnesses. Each country has its own standards. These rules keep pets and people safe. You need to check chemical safety, strength, and labels. The table below shows important rules and what to look for:

Topic | Key Info | Region |

|---|---|---|

Safety Standards | REACH (chemicals), GPSD (safety), Prop 65 (warnings) | EU, UK, USA |

Tensile Strength | Must withstand 7x pet’s weight | Global |

Certifications | CE (EU), UKCA (UK), CPS (USA, voluntary) | EU, UK, USA |

Chemical Safety | No harmful substances like lead or phthalates | EU (REACH), USA (Prop 65) |

Future Trends | ASTM standards, eco-friendly materials | Global |

Ask your supplier for certificates and test reports. Look for CE or UKCA marks on the harness label. These marks show the harness follows safety rules. In the USA, check for Prop 65 warnings if chemicals are used.

Chemical disclosure and REACH duties

You need to know what chemicals are in your harness. The EU REACH law says suppliers must tell you if the harness has any Substances of Very High Concern (SVHC) over 0.1% by weight. You must get safety data sheets and clear info for safe use. The table below lists what you should ask for:

Compliance Obligation | Description |

|---|---|

Information Provision | Suppliers must give info for safe use if SVHC is above 0.1% (w/w). |

Notification to ECHA | Importers/producers must tell ECHA if SVHC is above 0.1% (w/w) and over 1 tonne/year. |

Safety Data Sheet | Suppliers of substances on the Candidate List must give a safety data sheet to customers. |

SCIP Notification | Suppliers of articles with SVHC above 0.1% (w/w) must send a SCIP Notification to ECHA. |

To check chemical safety and labeling, always ask your supplier for a statement about SVHCs. Make sure you get all papers that explain safe use and answer questions.

How to describe strength without making safety guarantees

You want to show your harness is strong, but you should not make risky promises. Never say “escape-proof,” “guaranteed,” or “training results.” Use safer words instead. Here is a quick guide:

Risky phrases to avoid:

Escape-proof

Guaranteed safe

Prevents all escapes

Delivers training results

Safer replacements:

Tested to ASTM/ISO standards

Reinforced at high-stress points

Designed for durability and control

Meets recommended safety criteria

You help your team stay honest and focused on safety when you use clear, tested words.

You get the most from a big harness for dog when you use strong materials, reinforced stitching, and reliable hardware together. Box stitching and lots of stitches make the harness last longer and stay safe. Good hardware helps stop escapes and makes the harness last. A good fit spreads out pressure, lowers neck strain, and makes your dog more comfortable. Always look at supplier papers and use trusted test methods. Durability is very important for big dogs.

Checklist for RFQ:

Materials: strong webbing, soft padded lining

Hardware: rust-proof D-rings, safe buckles

Stitching: strong patterns, many stitches

Edge finish: smooth, stops rubbing

Test methods: ASTM, ISO

QC gates: check when received, during making, and at the end

Aspect | Evidence |

|---|---|

Neck Strain | Harnesses lower neck pressure, making them safer and fit better. |

Pressure Distribution | Good fit spreads pressure, stopping strain and escapes. |

Comfort | Padding and shaped handles help comfort and fit. |

FAQ

How do you check harness strength before buying?

Ask your supplier for ASTM D6775 webbing test reports and ASTM D1683 seam strength results. Review these documents to confirm the harness meets safety standards for large dogs.

What hardware should you look for in a big dog harness?

Choose stainless steel or zinc alloy D-rings and buckles. These metals resist bending and rust. Request ISO 9227 salt spray test results to verify corrosion resistance.

Why does harness fit matter for safety?

A proper fit spreads force across your dog’s body. Adjustable straps help you match the harness to your dog’s shape. This lowers escape risk and improves comfort.

How can you spot quality stitching on a harness?

Look for box-X or bar-tack patterns at stress points. Check that threads are thick and tightly sewn. Strong stitching helps prevent breaks during pulling or lunging.

What compliance documents should you request from suppliers?

Tip: Always ask for CE or UKCA marks, REACH chemical statements, and safety test reports. These documents show the harness meets US, EU, and UK safety rules.