You want to check if an outdoor dog bed supplier is good for your big order. Think about getting beds where the covers rip, seams break, or mold grows after just one season. Many buyers like you—over 70%—now look up information online, and 60% finish buying steps on the internet. You need more than just promises; you need real lab test results. Ask suppliers for reports on abrasion, hydrostatic head, UV resistance, mildew, and seam strength. Lab results that follow standards help make sure the material is safe, show if rules are followed, and lower risk with clear rules. This way, you can compare suppliers easily and keep the quality the same.

Key Takeaways

Always ask suppliers for lab test results. This helps make sure outdoor dog beds are good quality.

Pay attention to important tests like abrasion, hydrostatic head, UV resistance, mildew resistance, and seam strength.

Use a standard RFQ so suppliers know what you want.

Compare lab results using the same tests. This makes it fair when looking at different suppliers.

Set clear rules for each test. This helps lower risks when buying a lot at once.

Think about using third-party testing. This gives honest results and helps you trust your suppliers.

Check lab reports often. This helps you find problems early and keep quality high.

Keep all papers neat and in order. This helps you see changes and keep quality the same over time.

Why Lab Tests Matter for Outdoor Dog Bed Procurement

Common Outdoor Dog Bed Failures

You want your outdoor dog beds to last in all weather. Many buyers have problems like rips, leaks, flat filling, mold, and bad smells. These things happen when the materials or how they are made are not good enough for outside. Dogs can be rough on beds, and weather makes it harder. If you do not use lab tests, you might get beds that break fast or hurt pets.

Some dangers are hard to see and come from chemicals in cheap beds. Here are some common problems that lab tests can help you find:

Quality Issue | Description |

|---|---|

Flame Retardants | Can mess up hormones and hurt the brain. |

Formaldehyde | Can make it hard to breathe and cause skin problems. |

Pesticide Residues | Bad for pets, especially if they chew or lick the bed. |

Heavy Metals | Bad stuff like lead or mercury can build up over time. |

Phthalates & VOCs | Can make it hard to breathe or cause skin trouble from gases. |

Lab tests help you spot these problems before you buy a lot.

Ensuring Comparable Test Results

You need to compare suppliers with clear and fair data. If every supplier uses a different test or shares results in their own way, you cannot pick the best one. Always ask for lab reports that use the same rules. For example, make sure all abrasion tests use the same steps and finish point. Ask for photos at set times and clear numbers like cycles or grams. This helps you see which supplier is best for you.

Tip: Always tell your use case in your RFQ. For example, say if the bed will be in wet, sunny, or busy places.

A good RFQ should include:

Material structure (woven, knit, coated, etc.)

Coating type and thickness

Sewing details (thread type, stitch count)

Use case (outdoor, kennel, travel)

When to Use Third-Party vs In-House Testing

You can pick third-party labs or test in-house. Each way has good and bad points. Here is a quick look:

Factor | In-House Testing – Pros | In-House Testing – Cons | Outsourced Testing – Pros | Outsourced Testing – Cons |

|---|---|---|---|---|

Turnaround Time | Fast use of tools | May not have enough staff or tools | Good for normal tests | Can be slow from shipping or waiting |

Quality Assurance | You control the tests | Needs skilled workers | Uses outside rules | You watch less closely |

Confidentiality | Keeps info safe | Must keep data safe | Can sign deals | A little more risk |

Costs | Cheaper for big orders | Costs a lot to set up | Pay per test, no big setup cost | Can cost more if used a lot |

If you want answers fast and have the right tools, in-house is good. For special tests or when you need proof from others, third-party labs give trusted results.

Note: Always set what you accept in your RFQ. This helps suppliers know what you want and lowers risk.

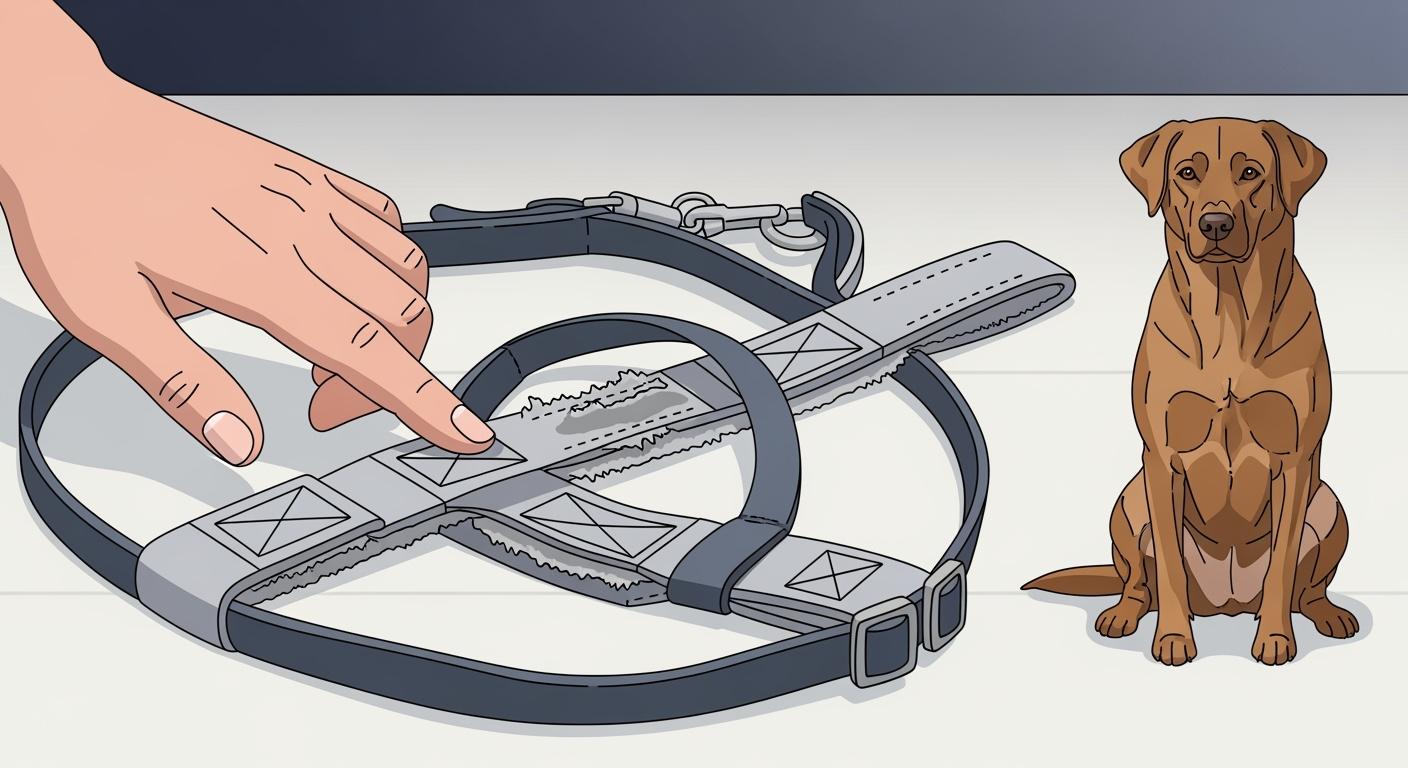

Abrasion Testing for Outdoor Dog Bed Covers

Abrasion testing helps you check if a fabric can handle daily wear and tear. You want your outdoor dog bed to last through rough use, weather, and cleaning. If you skip abrasion testing, you risk beds that rip, lose their coating, or look worn out after a short time.

Selecting a Standard Abrasion Method

You need to pick a test method that matches your product and market. Common standards include ISO, ASTM, or AATCC methods. Always ask your supplier which method they use. Make sure they use the same method for every batch. This helps you compare results and set clear acceptance criteria.

A good abrasion test report should include:

Test method (for example, ISO 12947 or ASTM D4966)

Test parameters (pressure, speed, sample size)

Defined endpoint (such as first hole, yarn break, or coating loss)

Units (cycles or grams)

Photo documentation at set intervals

Failure mode (what failed and how)

Tip: Ask for a sample report before you place a big order. This helps you see if the supplier can meet your needs.

Defining Test Endpoints and Photo Intervals

You must define when the test stops. Some buyers use the first hole as the endpoint. Others look for yarn break or when the coating wears off. Pick an endpoint that matches your use case. For example, if you want a waterproof bottom, you may choose coating loss as your endpoint.

Ask for photos at set intervals, such as every 5,000 cycles. This gives you a visual record of how the fabric changes over time. You can spot early signs of wear, pilling, or coating damage.

Here is a template you can use in your RFQ:

RFQ Abrasion Test Requirement:

- Test Method: [ISO/ASTM/AATCC number]

- Endpoint: [hole/yarn break/coating loss]

- Units: [cycles/grams]

- Photo Documentation: [intervals]

Avoiding Common Testing Pitfalls

Some suppliers may use different test methods or stop the test early. This makes it hard to compare results. Always check that the report matches your RFQ. Look for missing data, unclear endpoints, or no photos. If you see these problems, ask for a new test.

Abrasion resistance is critical for outdoor dog beds. Durable materials help keep the bed strong over time. Reinforced stitching and heavy-duty zippers also add to the life of the bedding. You want a waterproof bottom and a sturdy coated fabric to handle outdoor use.

When you request abrasion test data, use a clear template. This reduces risk and helps you qualify suppliers with validated results.

Hydrostatic Head & Waterproofing for Outdoor Dog Beds

Hydrostatic Head vs Water Repellency

It is important to know the difference between hydrostatic head and water repellency. Hydrostatic head tells you how much water pressure a fabric can take before it leaks. This number is shown in millimeters (mm). If the number is higher, the fabric is better at keeping water out. For outdoor pet sleeping bags, 3000mm hydrostatic head is a good goal. This means the material can stop water from leaking through.

Water repellency is different from waterproofing. Water repellency means water forms drops and rolls off the fabric. But it does not mean the fabric will stay dry under pressure or after a long time. You should check both things. Hydrostatic head is the best way to measure real waterproofing.

Reporting and Acceptance Criteria

You should always get a clear hydrostatic head test report. This report helps you set rules for what you will accept. It also lowers risk when you buy from suppliers. The report should have:

Test method (ISO, ASTM, or AATCC number)

Pressure rate (in mm/min)

Sample orientation (face, back, or seam)

Units (mm)

Pass/fail rules (like at least 3000mm hydrostatic head)

Photos of the test and results

When to retest if results are close to the limit

Here is a template you can use in your RFQ:

RFQ Hydrostatic Head Test Requirement:

- Test Method: [ISO/ASTM/AATCC number]

- Pressure Rate: [mm/min]

- Sample Orientation: [face/back/seam]

- Pass/Fail Criteria: [minimum hydrostatic head]

Tip: Always test seams in your samples. Seams are weak spots where leaks can start.

Seam Sealing and Leakage Checks

You want the whole outdoor dog bed to stay dry, not just the fabric. Seams, zippers, and closures can let water in if they are not sealed well. Ask your supplier how they seal seams, like with tape or welding. Ask for photos or videos of leak checks during testing.

Use this checklist when you look at waterproofing test reports:

Units and test method match your RFQ

Seams are tested in the samples

Clear rule for when a leak happens (first drop or wet spot)

Photos of seams and test results

When to retest is written

A good waterproofing process with clear rules helps you pick the right suppliers and lowers risk. You will get outdoor dog beds that stay dry in wet weather.

UV Resistance Testing for Outdoor Dog Bed Fabrics

Outdoor dog beds often stay in the sun for a long time. Sunlight can make colors fade and fabrics get weak. You want your products to look good and stay strong. UV resistance testing shows if the materials will last outside. Lab tests help you set clear rules and lower risk when you buy.

Testing Color and Strength Retention

You need to check color and strength after UV light. Some fabrics lose color fast. Others get weak and tear. A good UV test shows how much color changes and how strong the fabric stays. Ask your supplier for a report that includes:

Test method used

How long the fabric was tested

How much the color changed (like a grade or scale)

How much strength the fabric kept (as a percent)

Photos before and after the test

You can see common test methods and what they need in this table:

Standard | Region | Test Method | Key Requirements |

|---|---|---|---|

AS/NZS 4399-2017 | Australia/New Zealand | Evaluation and Classification of Sun-Protective Clothing | UPF values grouped; UV must be below set limits for each level. |

EN 13758-1:2006 | Europe | Test methods for clothing surfaces | UPF value must be over 40; average UV less than 5%. |

ASTM D6544-2012 | USA | Preparing Textiles for Ultraviolet Transmission Testing | Textiles are washed and exposed to light before UV testing. |

Including All Components in Scope

Test every part of the outdoor dog bed that faces the sun. This means the main fabric, thread, webbing, and handles. If you skip these, weak spots can form and the bed may break early.

Webbing is just one part. Make sure the stitching thread is UV-resistant too. Polyester thread is a common choice. This helps seams last as long as the webbing.

Ask your supplier to test all parts in the UV report. This gives you a full picture and lowers risk.

Standardizing Exposure Cycles

You want to compare suppliers with the same test times. Different labs use different machines and hours. Set a rule in your RFQ so you get results you can trust. Here are common test times:

Testing Method | Exposure Time |

|---|---|

QUV B | 500 Hours |

Xenon | 1000 Hours |

Accelerated Outdoor Exposure | Variable |

Actual Outdoor Exposure | 1 Year |

A good UV test report should include:

How long the fabric was tested

How the fabric was checked (color change, strength)

All parts tested

Photos as proof

Here is a template for your RFQ:

RFQ UV Exposure Test Requirement:

- Test Method: [ISO/ASTM/AATCC number]

- Exposure Cycle: [hours/wavelength]

- Evaluation: [color change/strength retention]

- Components Tested: [cover/thread/webbing/handles]

By using UV resistance tests with clear rules, you can pick good suppliers. This helps your outdoor dog beds last longer in the sun.

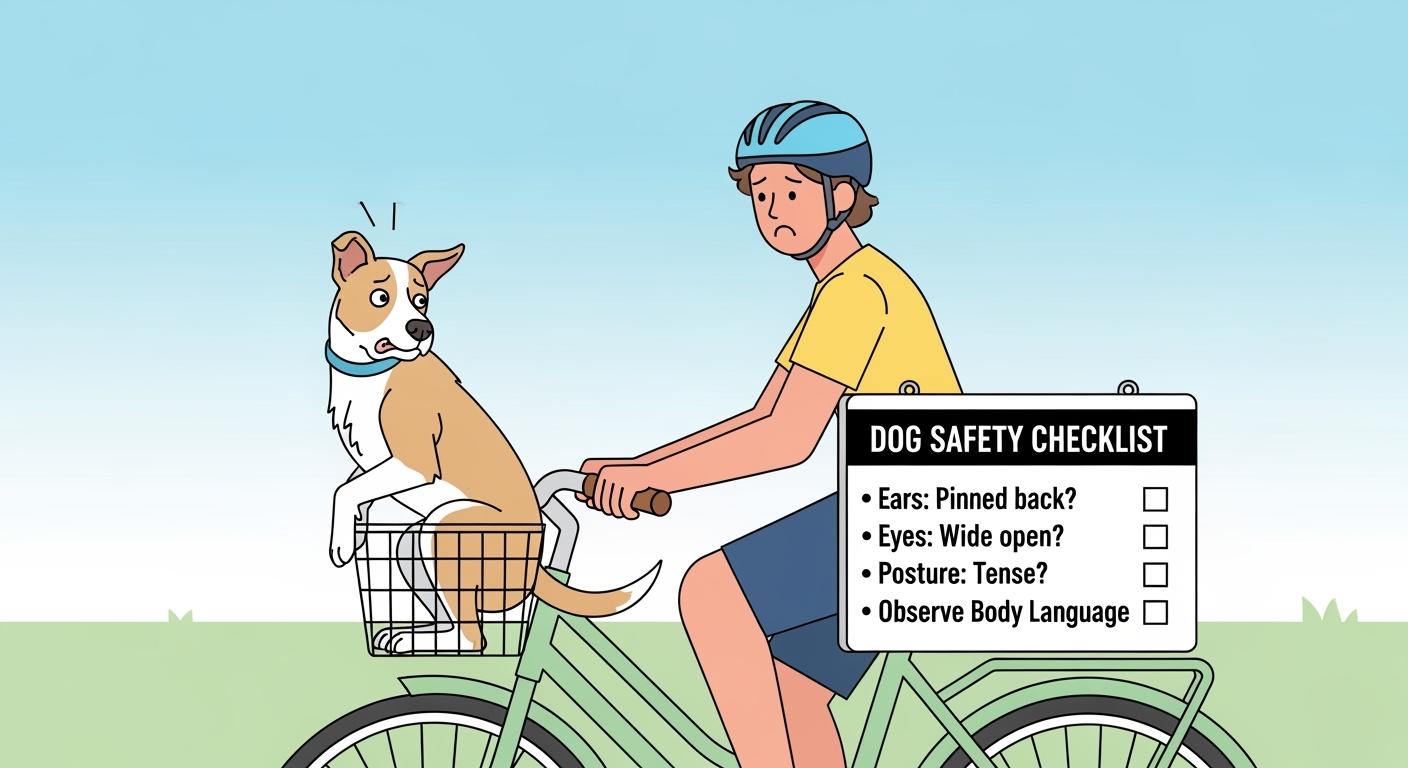

Mildew Resistance in Outdoor Dog Bed Materials

High-Risk Areas for Mold Growth

You need to keep your outdoor dog bed safe from mildew. This is very important in wet places. Raised dog beds help because they keep water away from where dogs sleep. Air can move under the bed, so the fabric dries faster. Humid places and spots with lots of rain are most risky for mold. If you put beds on wet grass or concrete, water can collect. Corners, seams, and the bottom of the bed hold water and dirt. These places often get mildew first. You should look at these spots when you check the beds.

Tip: Pick beds that sit above the ground. This helps keep them dry and lets air move around the fabric.

Defining Pass/Fail for Mildew Tests

You need clear rules for mildew resistance. Mildew-resistant fabric stays strong and looks good after getting wet. You should set rules for your supplier to follow. Use these points when you look at test results:

The fabric should not have any mold or mildew after testing.

The material should not get weaker or change color.

The bed should handle wet weather without falling apart.

If the fabric does not pass any of these points, you should not accept it. You lower risk by using good test methods and clear rules for passing or failing.

Required Supplier Documentation

You need the right papers from your supplier to check mildew resistance. Ask for these before you buy a lot of beds:

Document Type | Purpose |

|---|---|

Material Spec Sheet | Tells you about the fabric, coating, and treatments |

Process Change Notice | Lets you know if anything changes in how beds are made |

Storage/Packaging Advice | Shows how to keep beds dry when shipping |

You should ask for the mildew resistance test report. Ask for details like how the test was done, how big the sample was, and what happened. Suppliers must tell you if they change the materials or how they make the beds. You should also get tips on how to store and ship the beds so they stay dry.

Note: Always keep copies of supplier papers. This helps you see changes and keep quality good over time.

By doing these things, you can pick good suppliers and lower risk. You get outdoor dog beds that last longer in wet places.

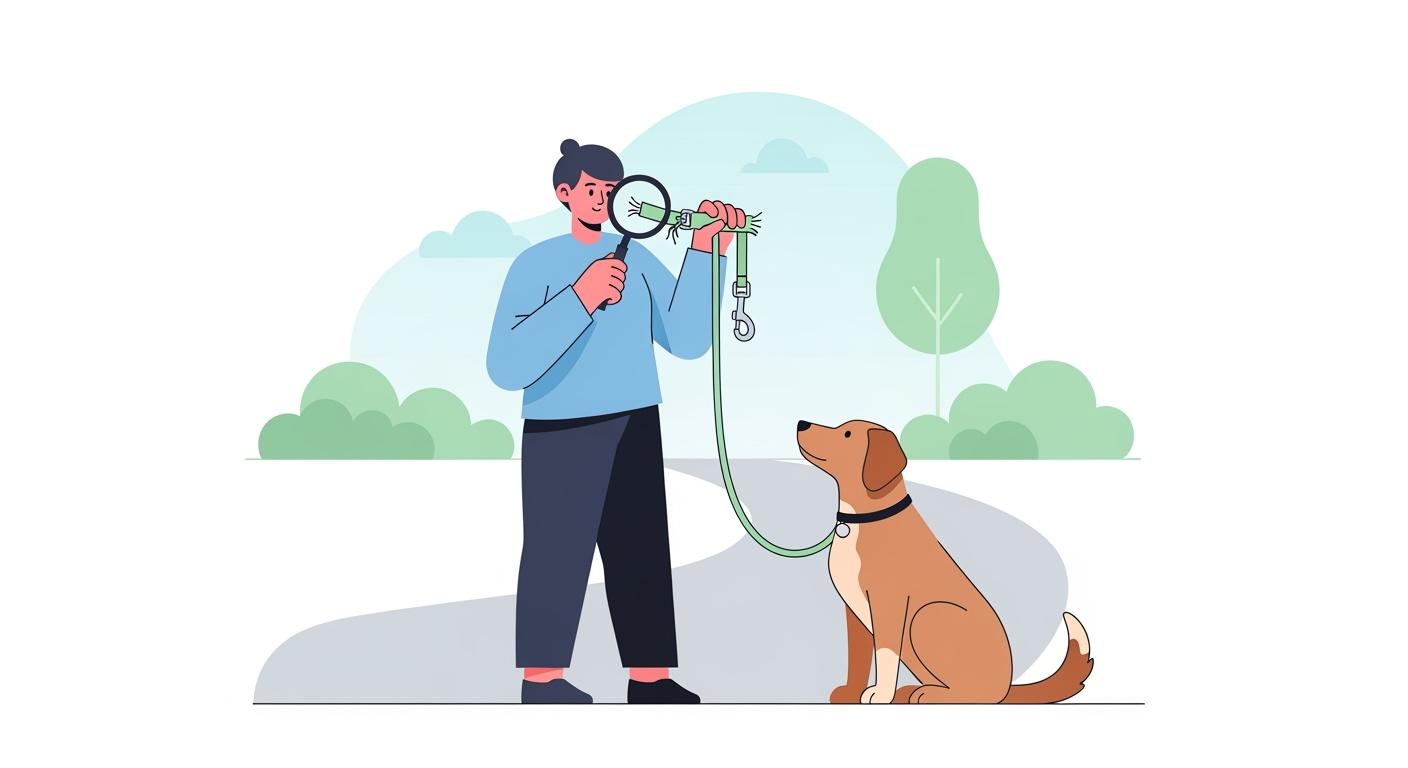

Seam Strength for Outdoor Dog Bed Construction

Seam strength plays a key role in how long your outdoor dog bed lasts. You want every seam to hold up under stress from dogs jumping, scratching, or dragging the bed. Weak seams can lead to ripped covers, leaking filling, or even safety risks for pets. You need to check seam strength with validated lab tests before you approve any supplier for bulk orders.

Key Seam Failure Modes

You should know the main ways seams can fail. This helps you set defined acceptance criteria and reduce risk. Here are common failure modes:

Seam Slippage: The fabric pulls away from the stitches, leaving gaps.

Thread Breakage: The thread snaps under force, causing the seam to open.

Fabric Tearing at Seam: The fabric itself tears next to the seam, even if the thread holds.

Popped Zippers or Handles: Zippers or handles pull out from the seam when lifted.

Tip: Always ask for photos of failed seams in the test report. This helps you see the real weak points.

Locking Seam Construction Specs

You need to specify how the supplier should build the seams. Locking seams, like double-stitched or bound seams, give extra strength. You should ask for details on:

Stitch type (lockstitch, overlock, etc.)

Thread material (polyester is common for UV resistance)

Stitch count per inch

Seam allowance (distance from edge to stitch line)

A clear construction spec helps you get consistent quality. You can use a table like this in your RFQ:

Parameter | Requirement |

|---|---|

Stitch Type | Double lockstitch |

Thread Material | UV-resistant polyester |

Stitch Count | 8-10 per inch |

Seam Allowance | Minimum 10 mm |

Defined specs make it easier to qualify suppliers and reduce risk of weak seams.

Pull Tests for Handles and Zippers

Handles and zippers take a lot of stress. You want to make sure they stay attached during use. Ask your supplier for pull test results. The report should include:

Force applied (in Newtons or pounds)

Direction of pull (straight, angled, etc.)

Failure mode (thread break, fabric tear, hardware failure)

Photos of the test and failed samples

Sample construction details

You can use this checklist for reviewing seam strength test reports:

Test method and force units are listed

Direction of pull is clear

Failure mode is described with photos

Sample construction matches your spec

Note: Validated pull tests with defined acceptance criteria help you select suppliers who deliver strong, safe products.

By following these steps, you can qualify suppliers who build outdoor dog beds that last longer and reduce risk for your business.

Creating a Buyer QA Checklist from Lab Results

You need a simple way to use lab test results. This helps you make a QA checklist that works for outdoor dog beds. The checklist lets you check suppliers, lower risk, and keep quality good. When you use a checklist, you make sure every supplier follows your rules. It also helps you find problems before customers get the beds.

Minimum Spec Table for Outdoor Dog Beds

Start by making a minimum spec table. This table shows the main tests, how to do them, and what counts as passing. You use the table to look at lab reports and pick the best supplier. Here is an example:

Test Item | Test Method | Unit | Endpoint/Criteria | Report Format |

|---|---|---|---|---|

Abrasion | ISO 12947 | Cycles | ≥ 20,000 cycles, no hole | Photos at intervals |

Hydrostatic Head | ISO 811 | mm | ≥ 3,000 mm | Photo of test |

UV Resistance | ISO 105-B02 | Grade/% | Color change ≤ 4, ≥ 80% strength | Before/after photos |

Mildew Resistance | AATCC 30 | Pass/Fail | No visible growth | Photo of sample |

Seam Strength | ASTM D1683 | N | ≥ 200 N, no seam slip | Failure photos |

Tip: Change your spec table when you use new materials or add features. This keeps your QA list up to date.

Qualification Workflow Steps

You need clear steps to check suppliers and keep quality high. Follow these steps:

Define Requirements

Write down what you want for your product. List the tests and rules. Share these in your RFQ.Request Lab Reports

Ask suppliers for lab reports that match your spec table. Make sure they use the same tests and show clear results.Review and Compare

Check each report with your spec table. Look for missing info, unclear results, or scores that do not meet your rules.Request Samples

Get samples tested by a third-party lab if needed. Use the same tests as in your spec table.Approve or Reject

Say yes to suppliers who meet all rules. Say no or ask for retests if results do not match.Ongoing QC

Check each batch often. Use your QA checklist to look at new lab reports and catch changes early.

Note: Keep all lab reports and messages from suppliers. This helps you watch quality and fix problems.

Change Control for Materials and Construction

You must watch for changes in materials and how beds are made. Even small changes can hurt quality or safety. Use a change control plan to lower risk:

Supplier Notification

Tell suppliers to let you know before they change anything.Requalification

Ask for new lab tests if something changes. Check new results with your spec table.Documentation

Save all change notes, new test reports, and updated spec tables.QA Checklist Update

Change your QA checklist and spec table when you approve a change. Share the new list with your team and suppliers.

Always use real lab data to approve changes. This keeps your outdoor dog beds safe and strong.

By doing these steps, you build a good QA system. You make sure every order meets your rules and your customers get safe, tough products.

You can pick outdoor dog bed suppliers by using simple steps. Look at lab test results that are checked and trusted. Compare the data with clear rules for what is good. Use a QA checklist each time you buy a lot of beds. Tell suppliers what you need and ask for sample reports. Use Stridepaw’s templates and checklists to lower risk and help you buy better. Stridepaw helps you build strong quality checks for OEM and ODM jobs.

Start now. Use Stridepaw’s tools to make checking suppliers easy and safe.

FAQ

What lab tests should I request from outdoor dog bed suppliers?

You need to ask for lab tests on abrasion, hydrostatic head, UV resistance, mildew resistance, and seam strength. These tests help you set clear rules for what is good. They also help you lower risk when you buy a lot of beds.

How do I compare lab test results from different suppliers?

Tell every supplier to use the same test method and report style. Use a spec table to look at results side by side. This makes it easy to pick the best supplier using real data.

Why is third-party lab testing important for outdoor dog beds?

Third-party labs give you results that are fair and trusted. You avoid reports that might be wrong or not complete. Third-party testing helps your quality checks and builds trust with buyers.

What should I include in my RFQ for outdoor dog beds?

Write down the test methods, rules for passing, and how you want reports. Add details about the material, coating, sewing, and how the bed will be used. Clear RFQs help suppliers know what you want and keep quality the same.

How often should I review lab test reports from suppliers?

Check lab test reports for every new batch or if anything changes. Looking at reports often helps you find problems early and keep quality high.

What is the difference between water repellency and hydrostatic head?

Water repellency means water rolls off the fabric. Hydrostatic head shows how much water pressure the fabric can take before it leaks. Hydrostatic head is better for checking waterproofing.

How do I handle changes in materials or construction from my supplier?

Tell your supplier to let you know before they change anything. Ask for new lab tests if they use new materials or ways to make the bed. Check the new results with your rules before you say yes.

Why should I test all components, not just the main fabric?

Handles, zippers, thread, and webbing can break if not tested. Testing every part makes sure the whole bed is strong and lowers the chance of weak spots.