If you sell a dog harness and related dog outdoor and travel gear, “carry dog bike” traffic can look confusing. Many searches are about bike riding safety, not only carriers. This article turns that demand into a B2B plan for assortments, packaging, QA, and pricing.

Search demand and seasonality for “carry dog bike” in US, UK, and EU

Takeaway: Treat “carry dog bike” as a mixed-intent cluster and plan content and SKUs around safety, fit, and stability.

Buyers should not assume this keyword is only about one product type. In many cases, shoppers mean “carry my dog while biking,” which can route to carriers, backpacks, and also dog harness use. Your job is to reduce mismatch, because mismatch drives returns.

Buyer actions:

- Map queries into clusters before you brief content or packaging.

- Align each cluster to a product page, a sizing guide, and a QA checklist.

- Add “fit and compatibility” gates to reduce avoidable returns.

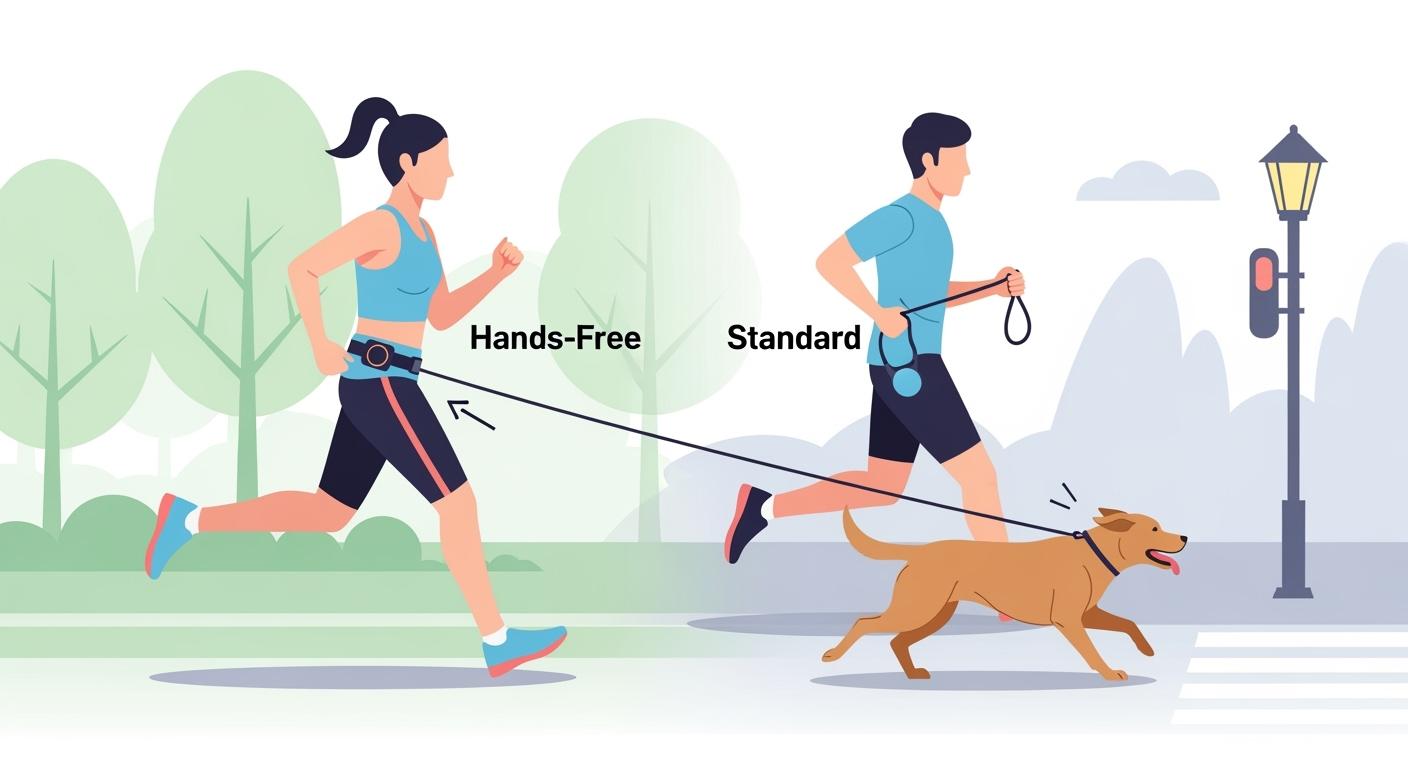

Cluster map: turn mixed intent into clear merchandising

Table: Keyword cluster map (what people mean, and what you should publish)

| Query cluster (examples) | Likely intent | Best matching dog product angle | Buyer action to reduce returns |

|---|---|---|---|

| carry dog bike, take dog on bike | High-level planning | Dog bike travel gear overview plus safety notes | Build a “choose the right gear” page with clear decision steps |

| dog bike carrier, bike basket for dog | Product selection | Dog bike carrier plus compatibility checklist | Add bike compatibility questions and photo-based support macros |

| dog backpack carrier for bike rides | Carry method | Dog backpack carrier and load stability | Add weight limits and posture checks on pack and listing |

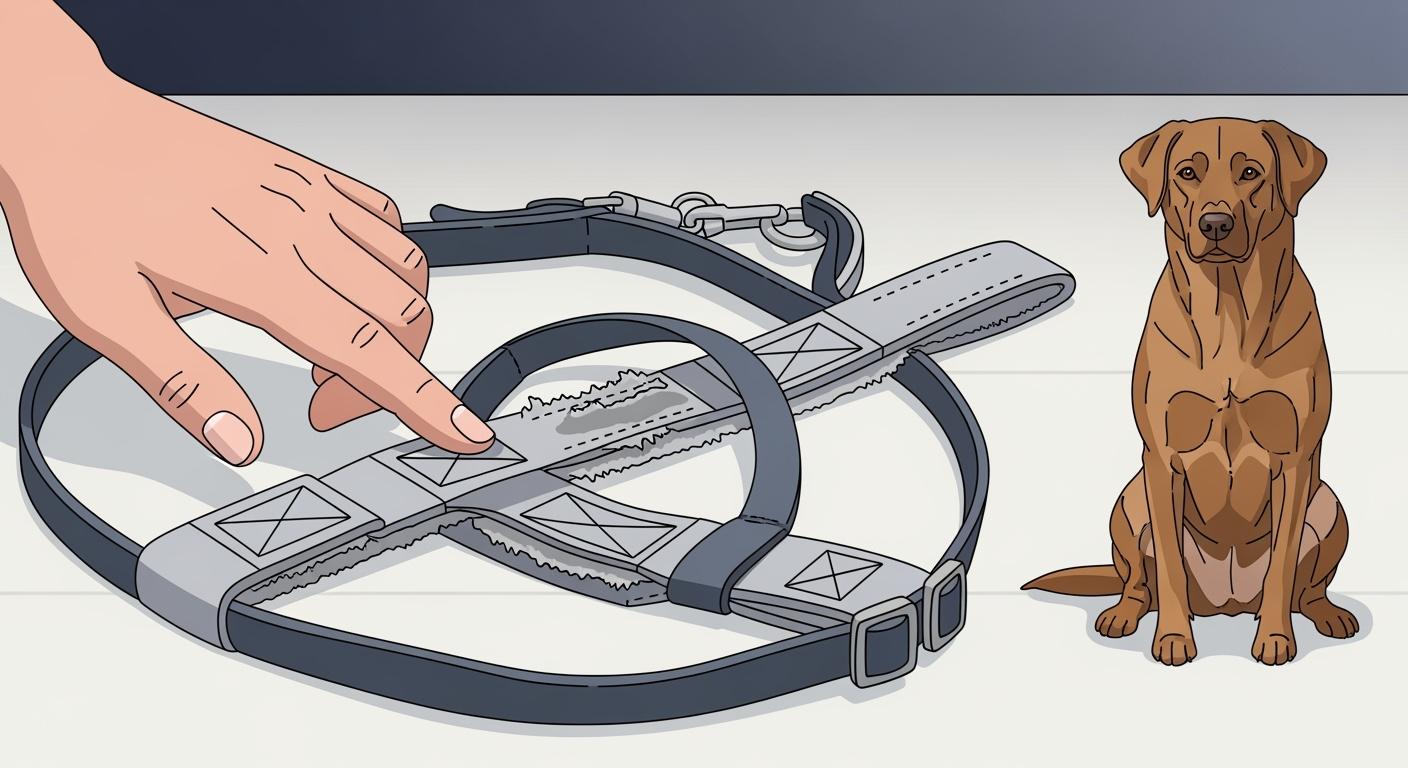

| dog harness for bike safety | Control and restraint | Dog harness fit and control points | Add measurement steps and “do not interfere with breathing” warnings |

| dog trailer vs carrier | Comparison | Dog trailer vs dog bike carrier comparison | Add a channel-specific selector and store staff cheat sheet |

| large dog bike options | Size constraint | Large-size solutions and size chart | Add dual-unit size charts and “in-between size” guidance |

Seasonality snapshot: plan content around when buyers plan

You do not need perfect volume data to plan. You need consistent timing logic. For US, UK, and much of the EU, bike and outdoor demand often rises in spring, peaks in summer, and softens in late fall and winter. Plan earlier than the season, because distributor buying cycles lead consumer demand.

Buyer actions:

- Publish education content 8 to 12 weeks before your peak ship window.

- Tie content to a size run and a returns playbook.

- Refresh listings before major marketplaces start seasonal audits.

Table: simple publishing calendar (repeat yearly, adjust to your channel)

| Month window | What buyers plan | Content to publish | Merchandising action |

|---|---|---|---|

| Jan to Feb | Pre-season assortment and reorders | “carry dog bike” cluster guide and fit basics | Lock size run, packaging dielines, and label text |

| Mar to Apr | Launch and staff training | Dog harness sizing guide and compatibility checklist | Train support team with macros and photo intake rules |

| May to Aug | Peak riding season | Troubleshooting and returns reduction content | Monitor returns tags and push CAPA (fix root cause) |

| Sep to Oct | Post-peak review | Warranty and defect review summary | Update supplier scorecards and revise weak components |

| Nov to Dec | Next season planning | SKU rationalization and cost-to-serve model | Reprice and renegotiate the terms for the next cycle. |

What cost to serve means for a dog harness

Takeaway: Cost to serve is the extra cost after the product ships, and distributors feel it first.

Cost to serve includes packaging labor, customer support, returns handling, and warranty claims. It is not just a factory price issue. If you ignore it, your distributor margin can look fine on paper and fail in real operations.

Buyer actions:

- Set a cost-to-serve budget per unit before you quote.

- Require evidence-based returns and warranty workflows.

- Use a standard set of assumptions across US, UK, and EU programs.

Here are consistent planning assumptions you can reuse in this article:

- Return rate planning range: 4% to 12%

- Warranty claim planning range: 1% to 5%

- Support cost per ticket: about 1 to 4 USD

- Return handling cost: about 6 to 18 USD

- Packaging cost: about 1 to 3 USD

- Distributor margin planning band: 18% to 35%

Packaging cost drivers for a dog harness program

Takeaway: Packaging is a cost lever and a returns lever at the same time.

Packaging changes labor time, damage rate, and dimensional freight. It also changes how many “wrong size” returns you get. For “carry dog bike” traffic, clear packaging reduces mismatched expectations.

Buyer actions:

- Choose a pack format that matches your channel.

- Add fit and measurement visuals to the pack.

- Add durable packaging for long-distance distribution lanes.

What changes packaging cost the most

Use these checks when you review packaging quotes:

- Pack size and thickness: bigger packs can increase dimensional freight

- Insert complexity: more inserts can increase packing time and errors

- Label count: more labels can increase labor and mislabel risk

- Window cutouts and hang tabs: can raise material cost and damage risk

Keep pack dimensions consistent when possible. A common unit envelope for a large dog harness program might be 10 to 15 in x 8 to 12 in x 3 to 6 in (25 to 38 cm x 20 to 30 cm x 8 to 15 cm). This is not a promise, but it is a useful planning band.

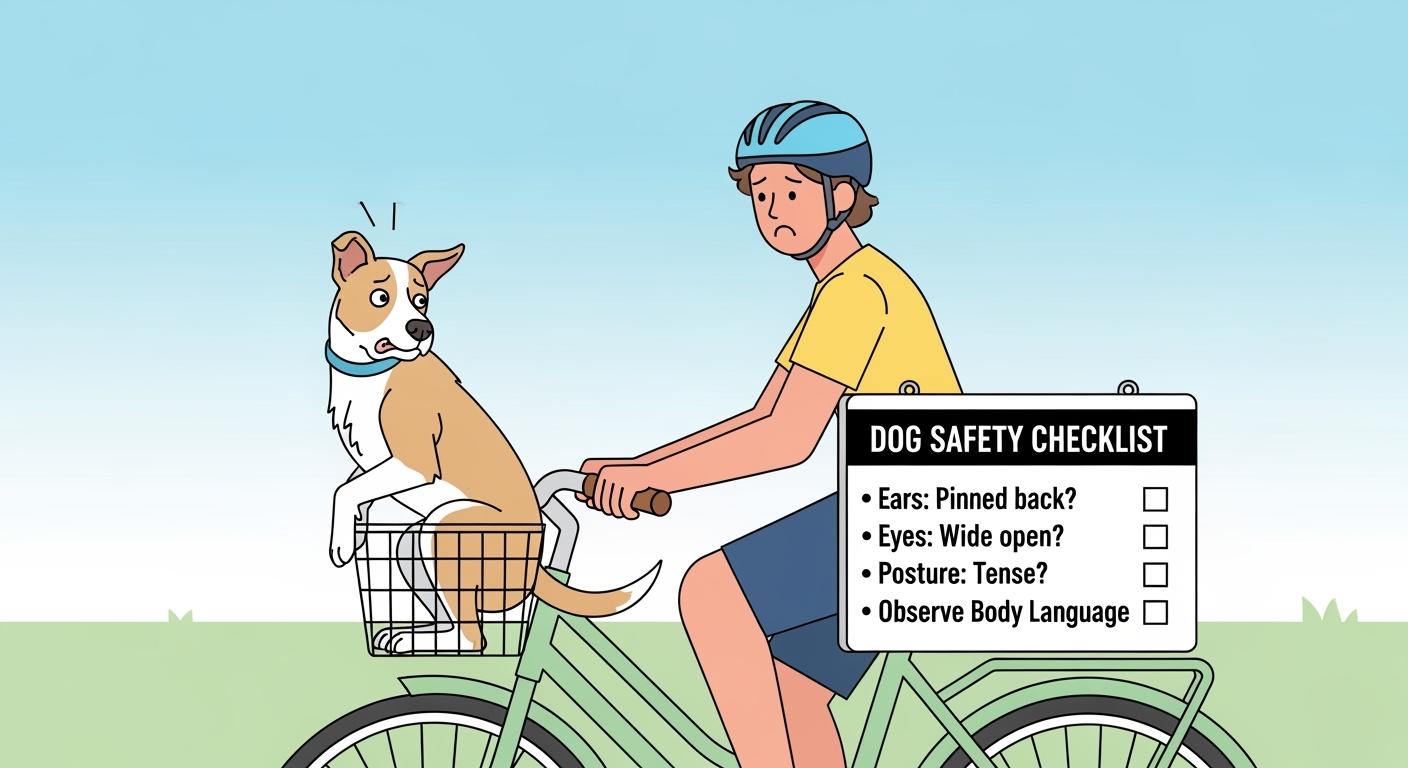

Packaging that reduces “wrong item” returns

For mixed-intent traffic like “carry dog bike,” confusion is normal. Packaging should prevent confusion.

Add these on-pack elements:

- Dual-unit size chart: chest girth in in and cm

- Simple measurement diagram: where to measure chest and neck

- Use-case icons: travel, outdoor training, bike rides

- Safety reminders: proper fit, supervision, and stop use if damage appears

Warranty cost drivers for dog harness use in travel and bike scenarios

Takeaway: Most warranty cost comes from a few repeat failure modes.

A warranty model should separate defect from wear and misuse. Large-size dog harnesses see higher load stress. Bike-related use can add vibration and moisture. That can raise complaints about hardware and stitching.

Buyer actions:

- Ask suppliers for load-point reinforcement details.

- Require hardware finish and corrosion resistance checks.

- Set a clear evidence rule for warranty claims.

Common failure modes to plan for

Use this list to build a warranty checklist:

- Stitch failure at D-ring and handle bases

- Webbing fray at adjustment points

- Buckle cracking or slipping

- Reflective trim peeling

- Padding edge wear that causes rubbing

Ask suppliers:

- Which stitch pattern is used at load points

- How webbing ends are finished to prevent fray

- How buckles are tested for repeated open-close cycles

- Whether hardware is tested for corrosion resistance

If buyers find that problems recur repeatedly, it is recommended that they consult a compliance expert. This is especially important for safety claims or accident reporting.

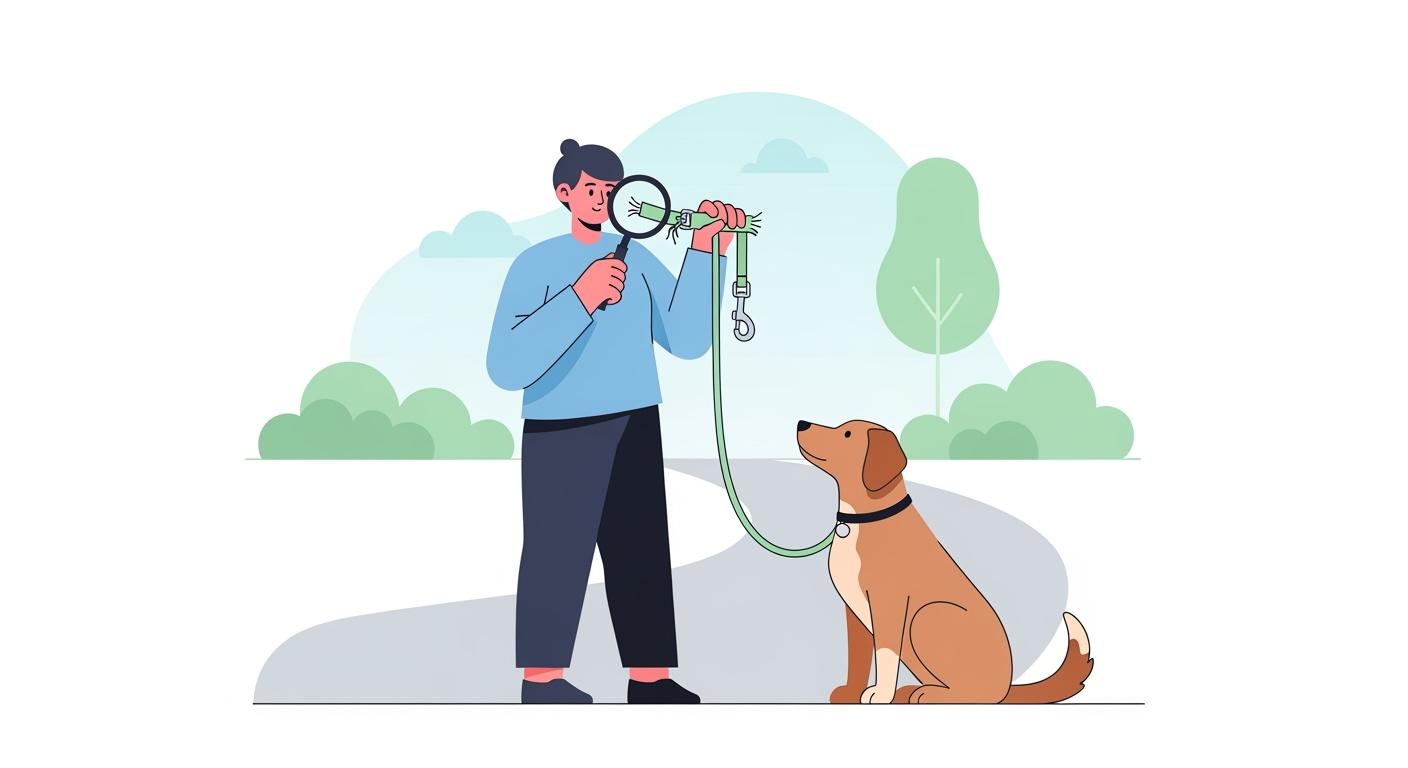

Returns cost drivers: fit issues and “carry dog bike” mismatch

Takeaway: Fit clarity is the fastest path to fewer returns.

Returns are often not defects. They are sizing errors, expectation gaps, or channel mismatches. For “carry dog bike,” many shoppers expect a carrier, not a harness. You can reduce that with better mapping between queries and pages.

Buyer actions:

- Publish a fit guide and link it to all related pages.

- Use photo intake rules before approving an RMA.

- Offer safe parts replacement when the issue is isolated.

Simple sizing steps that staff can follow

Use these steps in store training and in product pages:

- Measure chest girth behind front legs.

- Measure neck at the base, not the collar line.

- Check strap adjustment range for the next size up and down.

- Confirm no strap presses on the throat.

Planning bands for large size coverage:

- Chest girth: 24 to 44 in (60 to 112 cm)

- Neck: 14 to 30 in (36 to 76 cm)

Make sure the same measurement points appear in:

- Listing copy

- Packaging insert

- Customer support macros

Restock rules that protect margin

Not every return should be restocked. Define restock paths:

- A-grade restock: unopened, clean, tags intact

- B-grade: opened but clean, needs repack and inspection

- No restock: damaged, contaminated, missing parts, safety concern

Set a clear budget for handling returns, for example, $6 to $18 per item. This will help you decide whether replacing parts is more cost-effective than issuing a full refund.

Table 1: Cost-to-Serve Breakdown (simple model)

Takeaway: Put every post-ship cost into one table so pricing stays honest.

This table uses the planning bands stated earlier. Use your own data later, but keep the same structure.

| Cost-to-serve line | Typical planning range | What drives it | Buyer control lever |

|---|---|---|---|

| Packaging cost | about 1 to 3 USD | inserts, labels, pack size | simplify inserts, tighten dielines, reduce pack volume |

| Handling time | about 0.5 to 2 USD | pick-pack steps, relabeling | standardize carton labels and pack layout |

| Returns handling | about 6 to 18 USD | inspection, restock, disposal | photo intake rules, size clarity, restock grading |

| Warranty reserve | about 1% to 5% of units | repeat failure modes | reinforce load points, hardware QA, CAPA cycles |

| Support cost | about 1 to 4 USD per ticket | back-and-forth, unclear fit | macros, required photos, consistent size chart |

Buyer action:

- Use this table in every distributor quote review.

- Compare programs by total cost to serve, not only unit cost.

How to price to protect distributor margins

Takeaway: Pricing must cover allowances and still hit a realistic distributor margin band.

Many teams set a price, then add discounts, then hope returns stay low. A safer approach is to start from landed cost and add known allowances. Then you check if the distributor margin band still works.

Buyer actions:

- Set allowances before you promise price protection.

- Offer service options as tiers, not free add-ons.

- Tie margin to the level of support and returns handling you provide.

Pricing waterfall logic in plain words

Use these steps:

- Start with your planned list price.

- Apply trade discounts and promos.

- Subtract landed cost and inbound handling.

- Subtract allowances for returns, warranty, and support.

- Check the distributor margin band, then adjust.

Keep the distributor margin planning band consistent: 18% to 35%. This is a planning band, not a guarantee.

Table 2: Pricing Waterfall to Protect Distributor Margin

Takeaway: A waterfall makes it clear where margin is lost.

| Step | Line item | Example way to think about it | Buyer action |

|---|---|---|---|

| 1 | List price | set by channel position | confirm price ladder across sizes |

| 2 | Trade discounts | planned, not random | lock promo rules in terms |

| 3 | Landed cost | product plus freight and duties | reduce pack volume, stabilize materials |

| 4 | Returns allowance | tied to 4% to 12% planning | reduce sizing errors and mismatch |

| 5 | Warranty allowance | tied to 1% to 5% planning | upgrade load points and hardware |

| 6 | Support allowance | 1 to 4 USD per ticket planning | enforce photo intake and macros |

| 7 | Target distributor margin | 18% to 35% planning band | align services to margin tier |

Buyer action:

- Run two scenarios: conservative and best case.

- Use the same assumptions in US, UK, and EU for planning.

Operational checklist: what to request, check, and print

Takeaway: A short checklist prevents long disputes later.

Use this list for product teams, QA, and category managers. Each item should become a file, a label, or a test record.

Buyer actions to request from suppliers:

- Size chart with dual units and clear measurement points

- Pack dielines and label artwork for approval

- Hardware specs and test method notes

- Stitch map showing reinforcement at load points

- Lot marking plan for traceability

- Inspection plan using AQL (a basic defect-check rule)

Buyer actions to check at goods receiving:

- Pack size against plan, such as 10 to 15 in x 8 to 12 in x 3 to 6 in (25 to 38 cm x 20 to 30 cm x 8 to 15 cm)

- Label presence: origin, material content, care, warnings, SKU

- Buckle function and strap adjustment range

- Stitch quality at D-ring and handle bases

- Reflective trim attachment and edge binding quality

Buyer actions to print on packaging and inserts:

- Dual-unit size chart: chest 24 to 44 in (60 to 112 cm), neck 14 to 30 in (36 to 76 cm)

- Fit steps in 3 to 5 bullets

- Safety notes: supervision, correct fit, stop use if damaged

- Support intake: required photos for fit and defect checks

In summary: a B2B publishing plan to reduce return rates.

Takeaway: Content should not just drive traffic. It should reduce service cost.

When you publish for “carry dog bike,” your best B2B outcome is fewer wrong-product returns. That happens when content, packaging, and support use the same decision logic.

Buyer actions:

- Publish one main guide that routes to the right product type.

- Publish one dog harness sizing guide and link it everywhere.

- Publish one returns reduction playbook for internal training.

Suggested content pieces that map to cost-to-serve:

- “Carry dog bike gear selector for buyers” with a clear decision tree

- “Dog harness sizing for travel and outdoor training” with dual units

- “Returns and warranty playbook for distributors” with photo intake rules

- “Packaging checklist for major marketplaces” without brand names