If you’re sourcing harnesses for large dogs, service costs can quickly eat into your profits. This guide aims to help buyers price large dog products appropriately and provide clear packaging, warranty, and return policies. You’ll receive a simple model that your team can replicate for retailers, distributors, private label, and OEM/ODM projects.

Quick Reference Card

| Card Name | Baseline Range or Standard | How to Use It |

|---|---|---|

| Card: Baseline MOQ | Typical range: about 500–1,000 units per color-size run (project dependent) | Use for line planning and distributor forecast gates. |

| Card: Lead Time | Typical range: about 25–45 days ex-works for repeat orders | Use for replenishment, promo timing, and safety stock logic. |

| Card: Sample Cycle | Typical range: about 10–25 days per sample round | Use to plan pre-season approvals and packaging sign-off. |

| Card: Baseline Return Rate | Conservative planning range: about 4%–12% (channel and fit clarity matter) | Use as your return allowance input in pricing. |

| Card: Baseline Warranty Claim Rate | Conservative planning range: about 1%–5% (depends on materials and QC) | Use as your warranty reserve input in pricing. |

| Card: Return Handling Cost | Typical range: about 6–18 USD per returned unit (inspection + restock path) | Use to decide “replace parts” vs “full refund” policies. |

| Card: Packaging Cost | Typical range: about 0.8–2.8 USD per unit (insert, polybag, carton, labels) | Use when you choose retail-ready vs ship-in-own-container. |

| Card: Support Cost Per Ticket | Typical range: about 1–4 USD per ticket (labor + tooling) | Use for cost-to-serve and defect dispute workflows. |

| Card: Distributor Margin Target | Common planning band: about 18%–35% (category and services vary) | Use to back-calculate landed cost and allowances. |

| Card: Size Coverage | Chest girth planning band: 24–42 in / 60–106 cm Neck planning band: 14–30 in / 36–76 cm Strap webbing width planning band: 0.8–1.5 in / 20–38 mm | Use to define your size run and reduce “wrong size” returns. |

| Card: Pack Size Envelope | Unit pack outer envelope: 10–15 x 8–12 x 3–6 in / 25–38 x 20–30 x 8–15 cm | Use to manage dimensional freight and shelf fit. |

| Card: Replace-Parts Threshold | Plan to replace parts when defect is isolated and safety risk is low | Use to lower returns while staying safety-first. |

| Card: Label Pack (Baseline) | Country of origin, importer info, material content, care notes, warnings, SKU/barcode | Use to build a compliant listing and carton label set. |

Mini Glossary (buyer-friendly)

- MOQ (minimum order quantity): the smallest order size a factory accepts.

- AQL (acceptance quality limit): a basic defect-check rule for inspections.

- RMA (return merchandise authorization): the return approval record.

- CAPA (corrective and preventive action): how suppliers fix root causes.

- Landed cost: product cost plus freight, duties, and inbound handling.

- Dimensional weight: shipping pricing based on package size, not only mass.

- Chargeback: retailer or platform fee for non-compliance or process misses.

- Sell-through: how fast inventory sells versus what was shipped in.

- Assortment: the planned mix of sizes, colors, and styles.

Who should use this cost-to-serve model

This model is for teams that sell a dog harness through a channel, not just direct. It helps you price service work, not only materials. It also helps you set rules that reduce preventable returns.

| Buyer Type | What They Care About | What This Model Solves |

|---|---|---|

| Retailers and category managers | Return rates, shelf fit, planograms, compliance files | Packaging choices tied to returns and store labor. |

| Distributors and wholesalers | Margin, claims workflow, service load, replenishment | Warranty and returns allowances tied to real work. |

| Pet brands and private label teams | Spec control, differentiation, cost stability | Spec-to-cost choices that reduce long-term claims. |

| OEM/ODM sourcing and supply chain | Lead time, risk, inspection gates, change control | A shared language for QC, CAPA, and packaging sign-off. |

| E-commerce sellers on major marketplaces | Listing accuracy, packaging integrity, dispute proof | Fit clarity and evidence rules to reduce disputes. |

| Centers and service providers | Durability, controllable specs, repeat orders | Size logic and build checks for consistent procurement. |

Use-case map for a dog harness program across channels

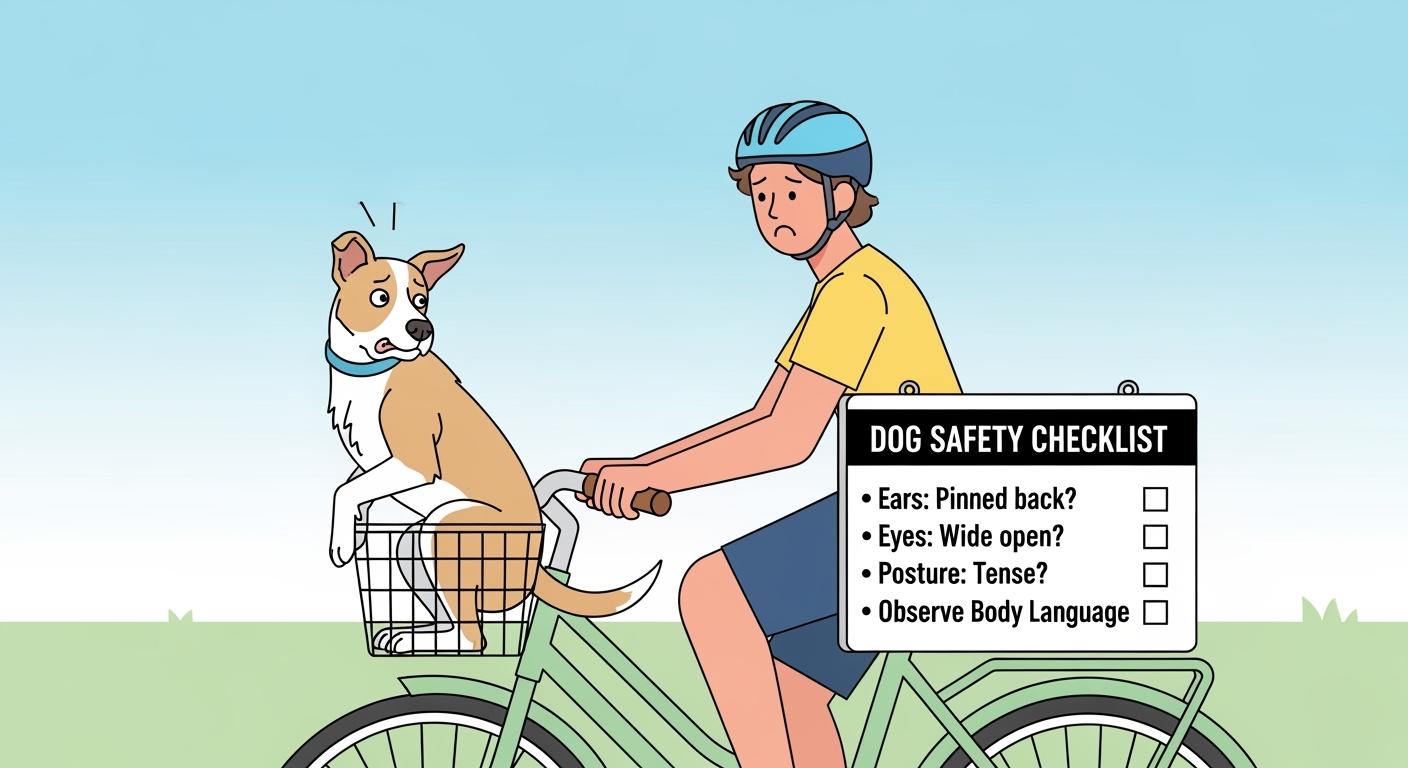

A cost-to-serve model starts with where the harness is used. Use-cases drive sizing errors, wear points, and return reasons. Map them before you lock your assortment.

Travel & Commute

Travel use increases rubbing and stress on buckles. It also increases “fit surprise” at first use. Use clear measurement rules to reduce returns.

- Car restraint pairing and stable attachment points.

- Quick on-off time for drivers and staff.

- Label clarity for safety reminders and care steps.

Outdoor Training & Safety

Training use raises pull force and abrasion risk. It also increases feedback about “control” and “comfort.” Your build spec should match the use intensity.

- Front and back attachment options for control.

- Reinforced stitch paths at load points.

- Reflective elements for low-light handling.

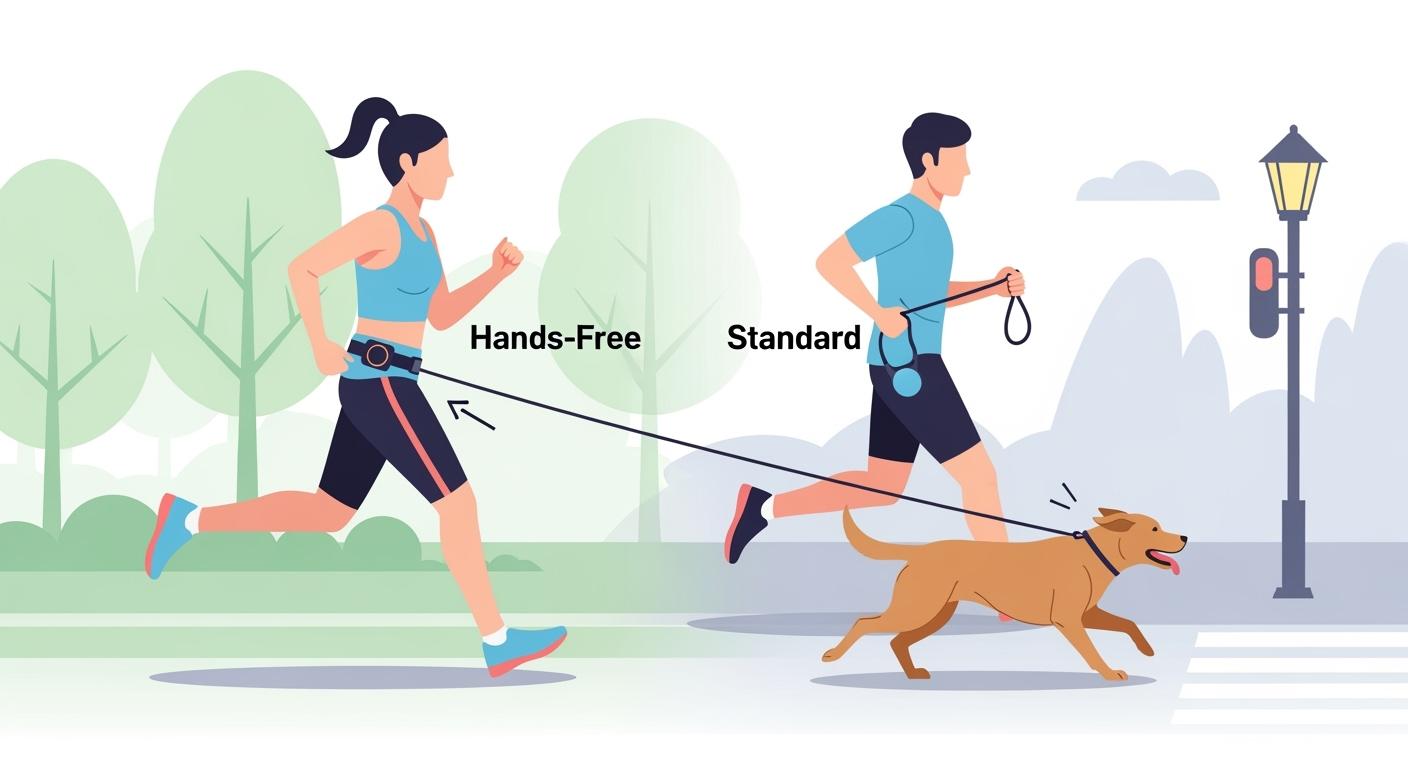

Sports & Enrichment

Sport use adds motion and sweat exposure. It increases seam fatigue and odor complaints. Materials and finishing matter more here.

- Breathable padding that dries fast.

- Hardware that resists corrosion from moisture.

- Easy cleaning steps aligned to Card: Label Pack (Baseline).

CTA: For channel-specific assortment help, use the internal form: Talk to the StridePaw sourcing team.

Specs and sizing for a big harness for dog assortments

Most returns in harness programs start with sizing confusion. Your job is to make sizing repeatable for staff and end users. Build a simple measurement flow and lock it in packaging and listings.

Measurement points your team should standardize

Use the same points in every channel file. That reduces disputes when returns happen. It also improves reorder confidence.

- Chest girth: measure the widest rib area behind the front legs.

- Neck: measure at the base of the neck, not the collar line.

- Back length fit check: confirm the harness does not sit on soft tissue.

- Strap adjustment range: confirm slack for winter coats and body variance.

How to build a “big size” run without over-SKU

Use size coverage bands, not size names alone. Start with Card: Size Coverage to set the runway. Then decide how many sizes you can support in stock.

- Use overlapping chest ranges to reduce “in-between” returns.

- Keep buckle and strap lengths consistent within each size band.

- Use clear “how to measure” artwork on the pack.

- Use the same fit language across all listings and inserts.

Fit claims that are safer and easier to defend

Avoid absolute fit promises. Use fit checks that guide decisions and reduce misuse. Suggest professional advice when the case is complex.

- Say “designed to fit within the measured range,” not “fits all.”

- Ask for measurements when a return request starts.

- Recommend consulting a veterinarian or safety professional for special needs.

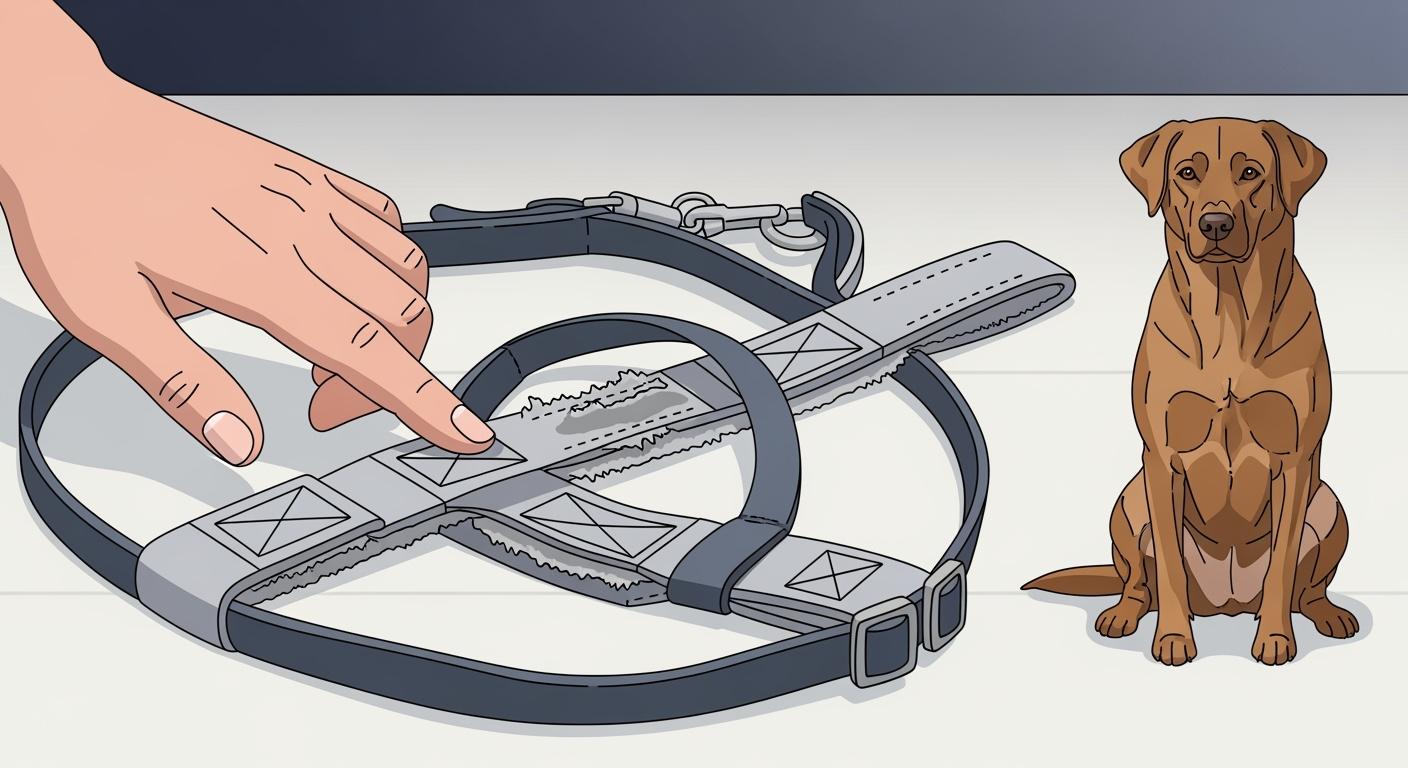

Materials and build details that cut warranty claims

Warranty cost often comes from small build choices. Pick materials that match abrasion and pull loads. Then define what “normal wear” means in your policy.

Material stack that helps reduce avoidable claims

Keep the stack simple and repeatable. Complexity increases variation across lots. Variation increases returns and disputes.

- Webbing: choose width bands aligned to Card: Size Coverage.

- Padding: prefer stable foam that holds shape after moisture exposure.

- Outer fabric: choose abrasion-resistant weave for training scenarios.

- Hardware: specify corrosion resistance for sweaty or wet use.

Build checkpoints that matter in large sizes

Large sizes magnify stress at stitch points. The same pattern can fail faster when scaled up. Add reinforcement where it matters most.

- Bar-tacks or box stitches at D-ring and handle bases.

- Edge binding quality to reduce fraying and skin rub.

- Symmetry checks to prevent twisting under pull.

- Stitch tension consistency to reduce seam splitting.

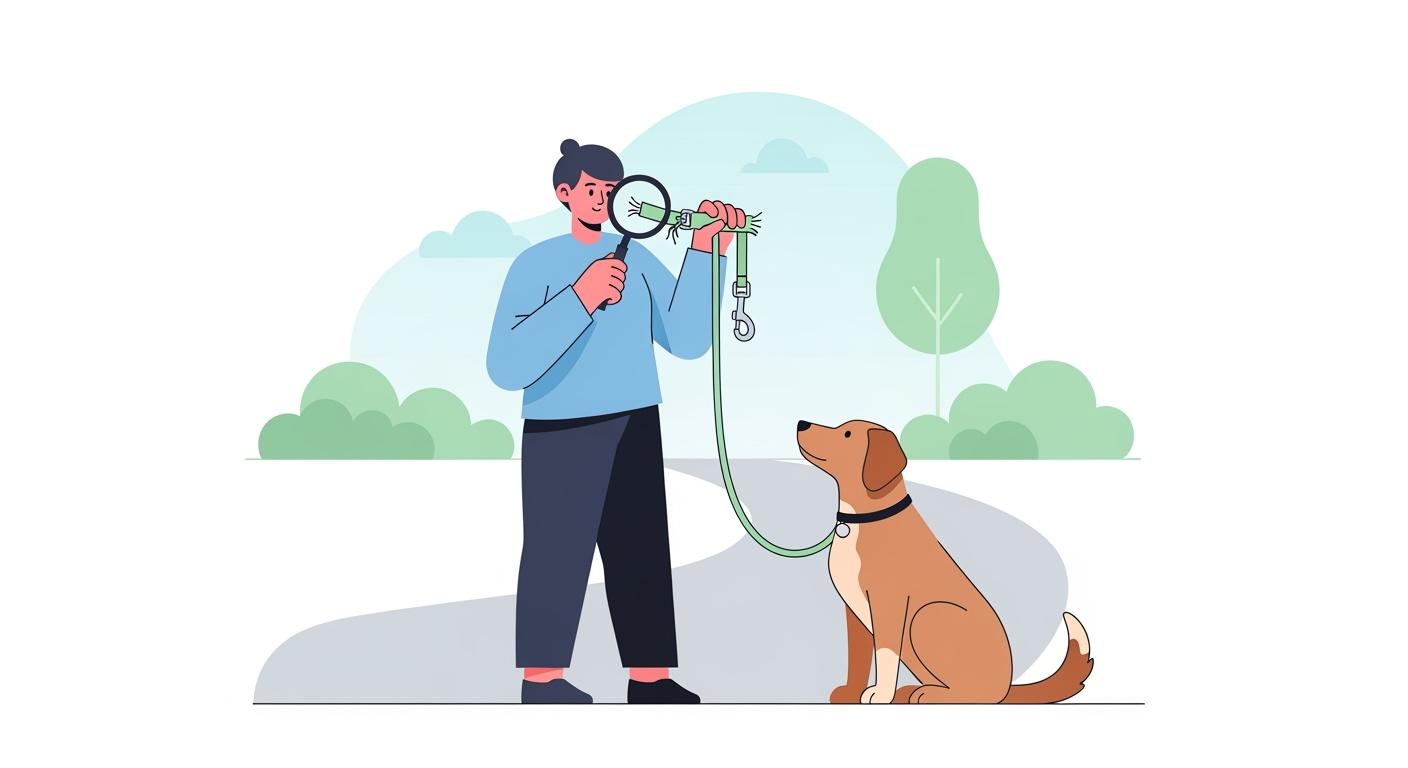

Quality and testing questions to ask before you place a PO

Quality costs less when you prevent defects early. Ask for proof on the parts that fail first. Then use a simple acceptance plan at receiving.

Pre-PO questions that reduce surprises

- What is the inspection standard used, such as AQL (a basic defect-check rule)?

- Which parts are lot-tracked for traceability?

- What is the change control process for webbing and hardware suppliers?

- How does the factory test stitching at load points?

- What are the most common defects, and what CAPA actions were used?

Receiving steps your DC can follow

Receiving should be fast and repeatable. It should also produce evidence for claims. Use photos and lot codes every time.

- Verify carton condition before opening.

- Check label pack items against Card: Label Pack (Baseline).

- Sample across sizes and colors from the assortment.

- Check adjustment range and buckle function on each sampled unit.

- Record findings for CAPA when repeats show up.

CTA: If you want a ready inspection checklist, use: Get the StridePaw catalog and QC checklist.

Compliance and labeling for dog harness distribution in EU and US

Compliance is about clarity and traceability. A dog harness touches safety, but it is not medical gear. Keep claims plain and keep your labels complete.

Label items to include in every channel file

A complete label pack reduces disputes. It also supports distributor handling and returns. Use Card: Label Pack (Baseline) as your baseline.

- Country of origin and importer or responsible party info.

- Material content and care guidance that matches the product.

- Warnings about proper fit and supervision during use.

- SKU, barcode, and batch or lot fields when applicable.

Listing and merchandising compliance checks

Major marketplaces often require proof files. Retailers may also require test reports or declarations. Build a compliance folder per SKU family.

- Product photos that match what ships in the carton.

- Size chart that matches the physical measurement points.

- Care and warning text aligned to the packaging insert.

- Traceability fields for returns and safety escalations.

Packaging, warranty, and returns: pricing a big harness for dog line for distributor margins

Price should cover service work, not only the unit. Packaging, warranty, and returns are the biggest hidden costs. Use the cards to set allowances before you set your distributor price.

Packaging choices that change your cost-to-serve

Packaging is a cost and a control tool. Better packs can reduce damage and returns. Use Card: Packaging Cost and Card: Pack Size Envelope together.

- Retail-ready packaging supports shelf speed but can increase cost.

- Protective inserts reduce damage but can raise dimensional freight.

- Clear sizing artwork reduces “wrong size” returns.

- Lot marking helps when defects cluster in a batch.

Warranty rules that protect both sides

Warranty terms should be clear and limited. They should also separate defects from wear and misuse. Use Card: Baseline Warranty Claim Rate for your reserve planning.

- Define “defect” with simple examples and photo requirements.

- Define “wear” and “misuse” in plain language.

- Offer parts replacement when it is safe and practical.

- Escalate safety concerns and pause use when risk is possible.

Returns workflow that reduces refund leakage

Returns should follow evidence rules. Evidence reduces disputes and fraud. Use Card: Baseline Return Rate and Card: Return Handling Cost for pricing.

- Require measurements for “wrong size” claims.

- Require photos for damage and hardware concerns.

- Use replace-parts paths guided by Card: Replace-Parts Threshold.

- Route repeat issues into CAPA tags and supplier reviews.

Unit economics table you can share with distributors

Keep the model simple. Use card references so teams stay aligned. Update the card ranges as your data improves.

| Cost-to-Serve Component | Input Reference | Owner | Decision It Drives |

|---|---|---|---|

| Packaging and labeling | Card: Packaging Cost, Card: Label Pack (Baseline) | Product + Packaging | Retail-ready vs ship-in-own-container strategy |

| Freight sensitivity | Card: Pack Size Envelope | Supply Chain | Carton design and master carton optimization |

| Returns allowance | Card: Baseline Return Rate, Card: Return Handling Cost | Commercial + Ops | Return policy, restock path, and pricing buffer |

| Warranty reserve | Card: Baseline Warranty Claim Rate | QA + Finance | Spec upgrades and claim workflow strictness |

| Support load | Card: Support Cost Per Ticket | CS + Ops | Macro packs, evidence rules, and training |

| Channel margin plan | Card: Distributor Margin Target | Sales + Finance | Distributor price, rebates, and service scope |

Simple pricing logic (plain language)

Start with your landed cost. Add allowances for returns, warranty, and support. Then confirm the distributor margin band using Card: Distributor Margin Target.

| Step | What to Add | Reference |

|---|---|---|

| Base | Unit cost and inbound handling | Use your internal landed cost file |

| Service allowances | Returns, warranty, and support buffers | Card: Baseline Return Rate, Card: Baseline Warranty Claim Rate, Card: Support Cost Per Ticket |

| Packaging choice impact | Pack changes that affect freight and damage | Card: Packaging Cost, Card: Pack Size Envelope |

| Channel target | Distributor margin and services scope | Card: Distributor Margin Target |

RFQ checklist and supplier scorecard you can copy into your sourcing pack

A good RFQ reduces follow-up and misalignment. It also shortens your sample cycle. Use the checklist below as your default template.

Copy-paste RFQ checklist

- Product scope: dog harness, large-size assortment, channel plan, and target use-cases.

- Size run: coverage based on Card: Size Coverage and your SKU limits.

- Materials: webbing width, padding stack, outer fabric, and hardware finish.

- Construction: stitch types at load points, edge binding, and reinforcement plan.

- Packaging: unit pack type, inserts, and label pack using Card: Label Pack (Baseline).

- Testing: what is tested, how it is tested, and what records you receive.

- Inspection: AQL plan (a basic defect-check rule), sampling approach, and pass/fail rules.

- Traceability: lot marking plan and defect tracking fields.

- Commercial: MOQ, lead time, and sample cycle aligned to Card: Baseline MOQ and Card: Lead Time.

- Warranty and returns: evidence rules, replace-parts paths, and CAPA expectations.

Supplier scorecard (simple scoring list)

Use a short scorecard so teams stay consistent. Score it the same way every quarter. Tie the score to reorder priority.

- Spec discipline: holds materials and patterns stable across lots.

- Build quality: clean stitching, stable padding, consistent hardware finish.

- Packaging control: meets Card: Pack Size Envelope and reduces damage risk.

- Inspection readiness: supports AQL checks and fast evidence sharing.

- CAPA speed: identifies root cause and prevents repeats.

- Lead time reliability: aligns to Card: Lead Time and communicates changes early.

- Claims cooperation: supports RMA evidence rules and fair resolutions.