You need a reflective dog collars QA documentation kit to keep your business and customers safe. This kit gives you a simple pack with retroreflection test results and traceability records. You can check that every collar is safe and follows the rules before shipping. More than 70% of pet car accidents happen when it is dark. Reflective collars help people see your dog from far away. They give quick visual alerts. 70% of these accidents happen because people cannot see well. You must use the right label words to avoid false claims and keep pets safe. Look at your current paperwork. Check if your supplier gives all needed test reports, label copy files, and traceability data for pet products. Use the table below to see the main rules for reflective pet products in the US and EU:

Region | Regulatory Requirement | Key Details |

|---|---|---|

EU | REACH Regulation | Limits on heavy metals, banned chemicals, documentation required |

EN 71 Standards | Mechanical testing, flammability testing | |

CE Marking | Required for products with electrical components | |

US | CPSC Regulations | Lead content limits, phthalate restrictions, choking hazard assessments |

FDA Regulations | Approved substances for food contact materials, migration testing | |

Canada | Consumer Product Safety Act | Heavy metal limits, textile regulations, bilingual labeling requirements |

Make sure your paperwork covers all these points. Missing or old files can hurt your brand. You can fix these problems with a full verification pack.

Your browser does not support the video tag.

Transcript:

You want to check how well reflective dog collars work. First, open the RA retroreflection report. Make sure the geometry is 12′/5°. The first RA should be at least 330 cd/(lx·m²). After testing, RA should be at least 100 cd/(lx·m²). If the value changes by more than 15%, check both directions. For label language, only allow claims about better visibility in low light when lit up. Do not allow any promise of safety or accident prevention.

Key takeaways:

Always check geometry and RA values on every report.

Use only approved label language for night-use claims.

Require traceability and change-control logs in your verification pack.

Never allow prohibited claims on packaging or listings.

Keep technical documentation for 10 years and traceability records for 6 years in the EU.

Key Takeaways

Reflective dog collars help dogs be seen at night. This lowers the chance of accidents. Always check RA values and shape in test reports. This helps make sure the collars are safe. Use the right label words so people are not confused about safety. Keep good records for at least 10 years to follow the rules. Gather all needed papers from suppliers to make sure the product is safe. Check and test the collars often to see if they last and work well. Use a change-control log to note any changes in materials or suppliers. Answer customer complaints fast to build trust and keep the product safe.

Why Reflective Dog Collars Documentation Matters

Nighttime Risks and Buyer Liability

There are real risks if collars do not reflect light. At night, it is hard to see pets and owners. Drivers, bikers, and people walking may not see your pet. If a driver misses your dog, an accident can happen. This can cause injuries or even death. In winter, it gets dark early, so be extra careful. Good paperwork shows your collars are safe. If your documents are old or missing, you could get in trouble. If there is a recall or lawsuit, bad claims can hurt your business. You could also break the rules.

Tip: Always keep your paperwork up to date. This helps your business and keeps pets safe.

Paperwork can help you stop recalls.

Good records lower your risk in court.

Clear paperwork makes customers trust you.

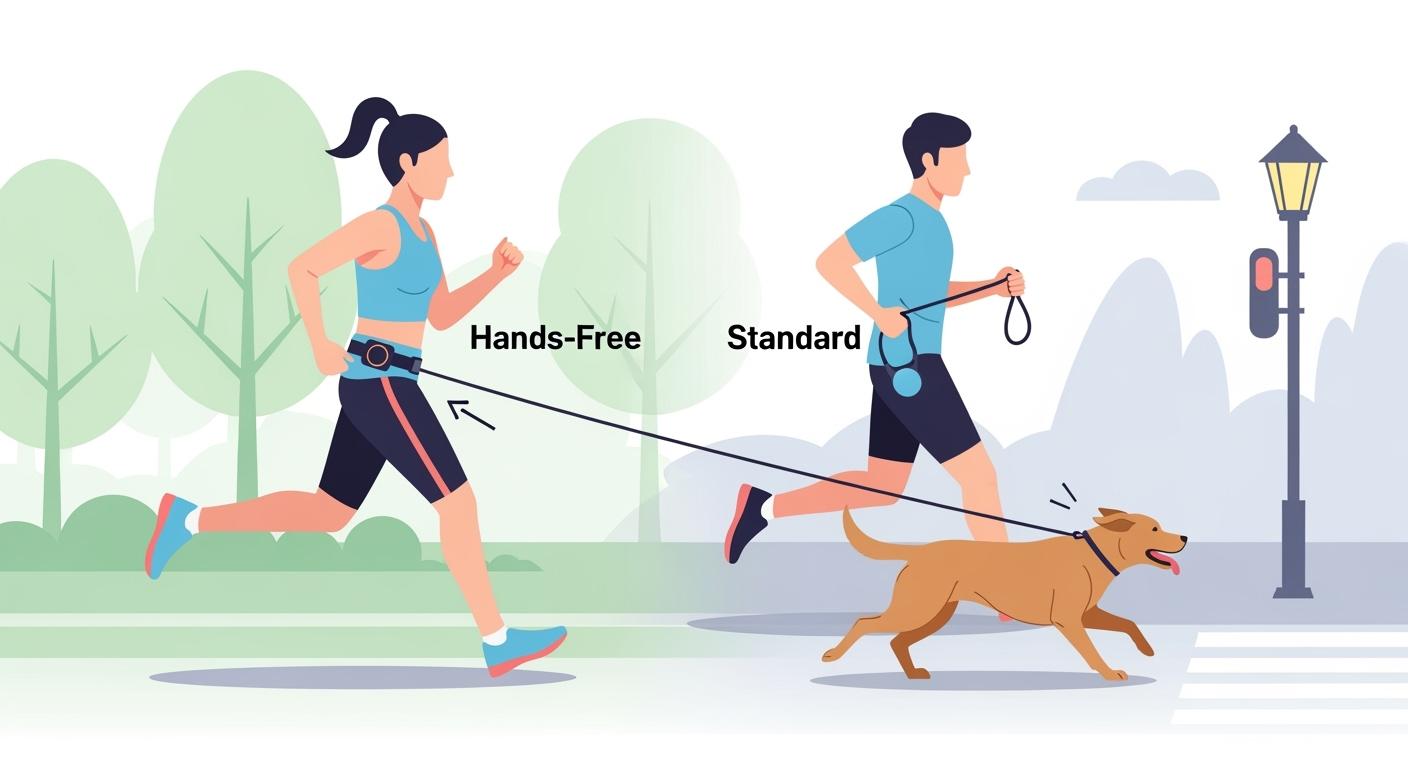

Reflective vs High-Visibility Claims

You need to know the difference between reflective and high-visibility. Reflective collars shine when light hits them at night. High-visibility products use bright colors for daytime. Do not mix up these two claims. The rules say you must use the right words on labels. If you use the wrong words, you could get in trouble or have a recall. Paperwork helps prove your claims and get certified. Never say things like “guaranteed visible” or “prevents accidents.” Only use approved words for night use.

Reflective claims: “Improves visibility in low-light when illuminated.”

High-visibility claims: “Bright colors for daytime visibility.”

Never promise safety or accident prevention.

RFQ and Supplier Onboarding Essentials

You need to ask for important papers when you start with a new supplier. These papers help you check if the products follow the rules. Your pack should have:

Document Type | Purpose |

|---|---|

Material Specification Sheet | Shows the reflective material is correct. |

RA Test Report | Checks if the collar reflects enough light. |

Traceability Dataset | Tracks codes, dates, and boxes for each batch. |

Change-Control Log | Lists changes, risks, and retest choices. |

Label File Set | Makes sure claims and warnings are right. |

Business Licenses | Proves the supplier is real and follows rules. |

Manufacturing Certifications | Shows the factory meets quality standards. |

Third-party Audit Reports | Checks if the supplier follows the law. |

Product Samples | Lets you test safety and quality. |

Material Safety Data Sheets (MSDS) | Shows materials are safe and not toxic. |

Testing Reports | Checks if the collar reflects light and follows rules. |

Compliance Documentation | Proves the product meets safety rules. |

You must collect all certificates and test reports. Keeping good paperwork helps you follow the rules. Always check your supplier’s papers before you buy.

Testing and Performance Targets for Reflective Dog Collars

Coefficient of Retroreflection (RA) Explained

It is important to know how reflective dog collars work at night. The main number to check is called the coefficient of retroreflection, or RA. This number tells you how much light the collar sends back to a light, like car headlights. Collars with high RA values are easier for drivers to see in the dark. For new collars, the RA should be at least 330 cd/(lx·m²) when tested at a 12′ angle and a 5° entrance. After testing for wear and tear, the RA should still be above 100 cd/(lx·m²). If the RA changes by more than 15% when you turn the collar, you must write down both numbers and use the lower one to decide if the collar is good.

Tip: Always look at the RA value and test angles on every report. A high RA means pets are easier to see at night.

Standardized Test Geometry and Reporting

Testing rules help you compare collars and keep your records clear. You must use the same test angles every time: 12′ and 5°. This rule makes the results fair and easy to check. You need a test report that shows these details. The report should have:

Test angles (12′ and 5°)

First RA number

RA number after testing

If RA changes by more than 15% when turned

Pass or fail result

Here is a checklist for your test report:

Field | Description |

|---|---|

Geometry | 12′ observation, 5° entrance |

Initial RA | ≥ 330 cd/(lx·m²) |

Post-exposure RA | ≥ 100 cd/(lx·m²) |

Orientation | Write down if RA changes more than 15%; use the lower number |

Pass/Fail | Clear result based on the rules |

You should use standards like EN 13356 for night visibility gear. These rules tell you how to test and write reports. They help you show your collars are safe.

Durability and Retention Requirements

Reflective dog collars must work well after being used outside. You want collars that last and stay bright. Tests check for UV light, scratching, water, and chemicals. You need to make sure your collars pass these tests before you buy or sell them.

Here is a table of important durability and retention needs:

Requirement | Description |

|---|---|

Material Durability | Look for UV resistance, scratch strength, and heat safety. |

UV Resistance | Use UV-safe plastics to stop yellowing or cracks. |

Water and Humidity Resistance | Stop water from hurting the shiny parts. |

Chemical Resistance | Make sure collars do not get ruined by cleaners or outdoor chemicals. |

Impact Resistance | Needed for pets in busy places. |

Long-term Outdoor Warranty | The best collars last 5–10 years outside. |

Compliance with Standards | Meet EN 13356 and other rules for shine and placement. |

Note: Always ask for test results and warranty details. These steps help you stop problems like fading, cracking, or losing shine.

You must check that every collar passes these tests. Good tests and strong materials help pets stay easy to see and safe. You protect your brand and follow all rules by using these standards.

Traceability and Change Control Documentation

Material Spec Sheet and Lot Tracking

You need a good way to track every batch. Start with a material spec sheet for each part. This sheet lists the main features. It helps you follow the rules. You should use lot tracking for each batch. Lot tracking follows the batch from supplier to product. This helps you keep up with rules. It also makes it easier to fix problems.

Component | Description |

|---|---|

Base Layer | Strong, weather-resistant material, like leather |

Cover Layer | Plastic or similar, weather-resistant, fire safe |

Visibility Feature | Light-emitting or glowing stuff for dark places |

Reflective Material | Reflective tape around the edge for better visibility at dawn and dusk |

Lot tracking should have the lot or roll ID, date received, finished-goods code, production date, and carton or pallet IDs. This info helps you follow the rules. It also helps you do fast recalls if needed.

Traceability Dataset Fields

You must collect and save key data for every batch. These fields help you show you follow the rules. They also make your paperwork stronger and more trustworthy.

Important traceability data fields are lot or roll ID, date received, finished-goods code, production date range, and carton or pallet IDs. You may need to track sensor types and the data from these sensors if your collars have smart features.

Keep these records neat and easy to find. This helps you answer rule questions fast. It shows you follow all the rules.

Change-Control Log and Triggers

Change-control logs are a big part of your paperwork. You need to write down every change to materials, steps, or suppliers. For each change, write what changed, when, risk level, if you retested, and who said yes. This log helps you follow the rules. It also helps your quality system.

Requirement | Details |

|---|---|

CE marking | Needed for selling in Europe |

Material traceability documentation | Needed from suppliers |

ISO 9001 certification | Good for making things right |

You must keep technical papers for 10 years and traceability records for 6 years to follow EU rules. These times help you show you follow the rules and protect your brand. Always update your change-control log when you make changes. This keeps your paperwork up to date. It helps you follow all rules for reflective dog collars.

Testing Plans and Verification for Product Safety

Photometric and Durability Testing Methods

You need a good plan to test reflective dog collars. This helps keep pets safe and follows the rules. Start with photometric testing. It checks how much light the collar reflects. Use the coefficient of retroreflection (RA) to measure this. Always test at 12′ observation and 5° entrance angles. The first RA must be at least 330 cd/(lx·m²). After the collar gets worn, the RA should stay above 100 cd/(lx·m²).

Durability testing is also very important. You should test collars with abrasion, bending, water, dirt, and UV light. These tests show if the collar still works after being used outside. Follow EN 13356 standards for every test step. This proves your collars meet the rules for pet products.

Tip: Always ask your supplier for all test papers and results. This helps you follow the rules and keeps your brand safe.

Sampling for QC and Re-Qualification

You need a smart plan to pick samples for quality checks. For incoming QC, choose samples from each lot or roll. Check if each sample meets RA and durability rules. For re-qualification, test samples from new lots, new suppliers, or after any change. This keeps your safety and rule records strong.

Here is a table to help you organize your sampling and paperwork:

Activity | Purpose | Sample Type | Evidence Needed | Rule/Standard |

|---|---|---|---|---|

Incoming QC | Check each new batch | Lot/roll samples | RA & durability test reports | EN 13356, internal SOP |

Re-Qualification | Confirm ongoing compliance | New supplier/lot | Updated test & trace records | EN 13356, change log |

Change-Control | Assess impact of changes | Changed material | Change log, re-test results | EN 13356, approval |

Keep all papers for every step. This helps you prove you follow all pet product rules.

Change-Control Testing

Change-control testing is very important for safety and rules. If you change materials, suppliers, or steps, you must test again. Write down every change in your change-control log. Include what changed, when, the risk, and if you tested again. Only say yes to changes that meet all rules and standards.

Note: Good change-control logs help you answer rule questions fast and fix safety problems.

You protect your pet brand and follow all rules by using these testing plans. Always keep your paperwork up to date. This helps you follow the rules and makes customers trust you.

Best Reflective Dog Collars: Label Copy and Claims

Approved Night-Use Language

You need to use simple and clear words on your labels. This helps you follow the rules and keeps your brand safe. The best reflective dog collars use label statements that match how the product works. You should add phrases that tell how the collar helps people see pets in the dark. Here is a label template you can use:

Reflective details improve visibility in low-light conditions when illuminated by external light (for example, headlights).

This product does not emit light and does not guarantee visibility in all conditions.

Always supervise your pet and use a leash as required; reflective materials do not prevent accidents.

You must not make promises you cannot prove. Only use claims that your paperwork can support. This way, you follow the rules and lower your risk.

Checklist of Prohibited Claims

Never use these claims on your packaging or online:

Guaranteed visible

Prevents accidents

100% safe

Vehicle-proof

Failsafe

Certified for roadway safety (unless you have full certification and documentation)

Required Warnings and Limitations

You must add warnings and limits to meet the rules. These statements help people know what the best reflective dog collars can and cannot do. Clear warnings also help your paperwork and lower your risk.

This product does not guarantee safety in all situations.

Reflective performance may decrease if the collar is dirty, worn, or damaged.

Inspect the collar before each use.

Replace the collar if reflective areas are cracked, peeling, heavily abraded, or no longer reflective.

Keep your warnings short and easy to understand. This helps people make safe choices and follow all the rules.

Care, Inspection, and Replacement

Good care steps help people keep the best reflective dog collars working well and safe. You should put these care steps on your label and in your paperwork:

Hand wash the collar and let it air dry to keep it shiny.

Use a fabric water shield spray to protect the shiny part.

Spray again every month or after rain, mud, or washing.

If the collar has removable patches, take them off before spraying and let them dry before putting them back on.

For sewn patches, cover the inside part before spraying the shiny side.

Spray two light coats and let each coat dry before spraying again.

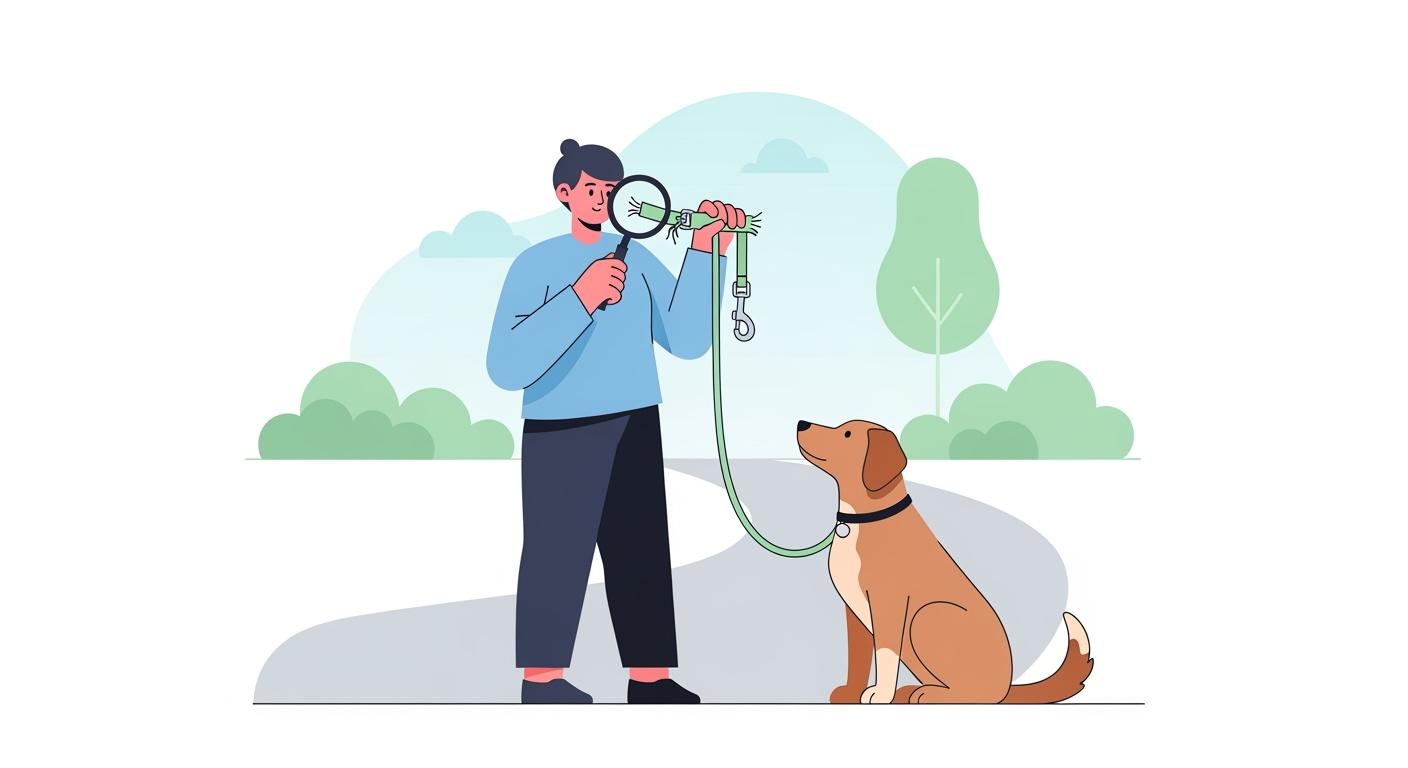

Check the collar before each use for cracks, peeling, or if it is not shiny anymore.

Replace the collar if you see damage or if it does not help your pet be seen.

You must keep all care and check steps in your paperwork. This helps you follow the rules and helps people keep their pets safe.

Production QC and Final Testing

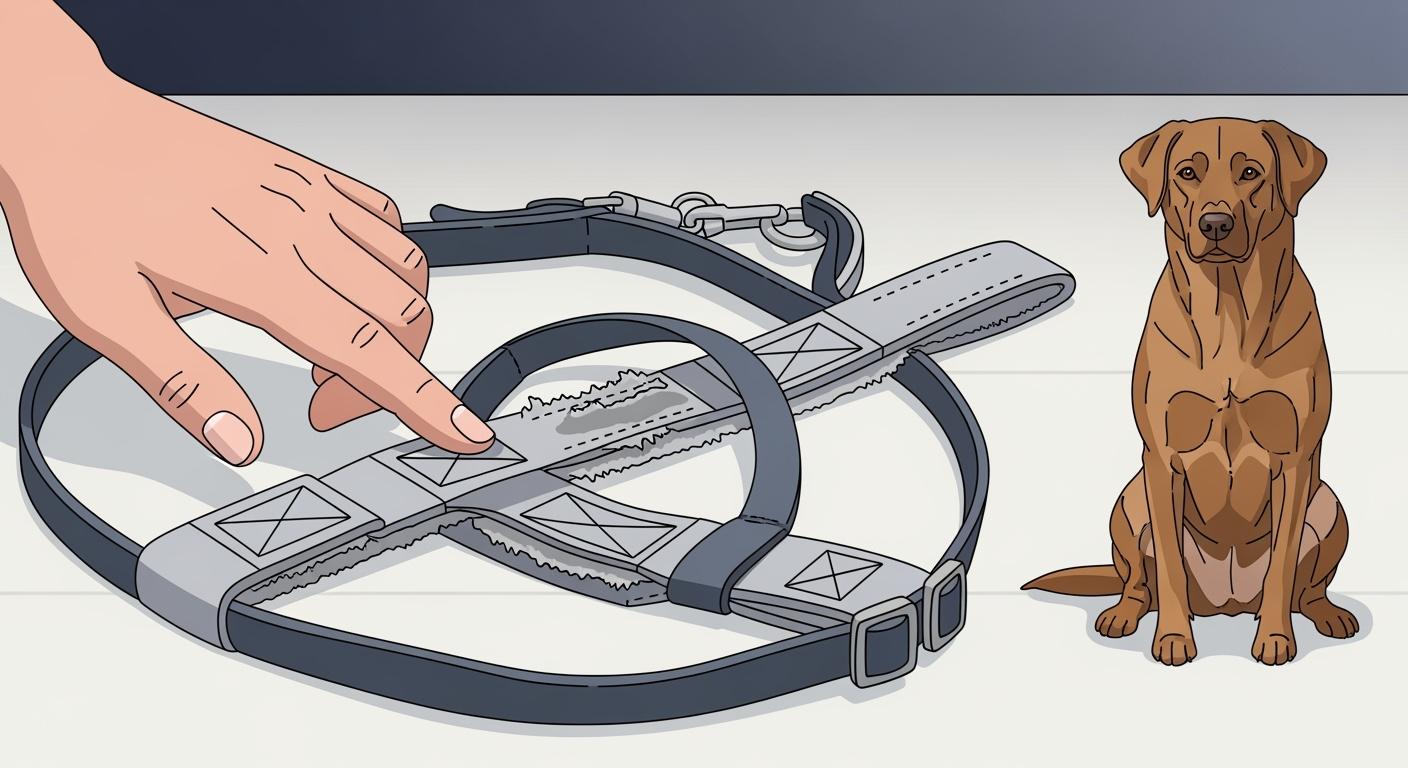

Incoming Inspection for Reflective Components

You need to check all materials before making collars. This step makes sure the reflective parts are good. Look at the tape, fabric, and hardware. Test the fabric to see if it is strong and will not rip. If your collar has LEDs, check if they are certified. Test the hardware to see if it is tough. If you find a problem, you can fix it before making the collars.

Tip: Always compare new materials to your approved list. This helps you find mistakes early.

In-Process and Placement Checks

You must watch the line while collars are made. These checks help you find problems fast. Make sure the shiny trim is in the right spot. Check that the stitches are strong and neat. Test the seams to see if they hold. If your collar has LEDs, check each one to see if it works. If your collar says it is waterproof, test that too. These steps help you keep the collars good and stop waste.

You can use a checklist while making collars:

Make sure the shiny trim is in the right spot.

Check that all seams are tight and strong.

Test LED lights to see if they work.

Test if the collar is waterproof.

Note: These checks help you fix problems before the collars are done.

Final Batch Inspection and Records

You need to check every collar before you ship it. This last check looks at the finished collar. Test if the collar fits and feels good. Check how well it shines using the RA number at the right angle. If your collar has LEDs, test the battery and see how long it lasts. Look at the box to see if it is damaged or missing labels. Write down all your results in your log.

Here is a table to help you with your checks:

Stage of QC | Checkpoints |

|---|---|

Incoming Quality Control (IQC) | Check raw materials, fabric strength, LED certification, hardware strength |

In-Process Quality Control (IPQC) | Watch the line, test seams, check LEDs, test waterproofing |

Final Quality Control (FQC) | Test finished collars, battery life, LED shine, fit, and box condition |

You should keep all your check logs for every batch. This helps you find problems and show you follow the rules. Good logs protect your business and help you fix things fast if you need to recall a collar.

Always keep your check logs neat and easy to find. This helps your quality system and makes buyers trust you.

Post-Market Monitoring and Incident Response

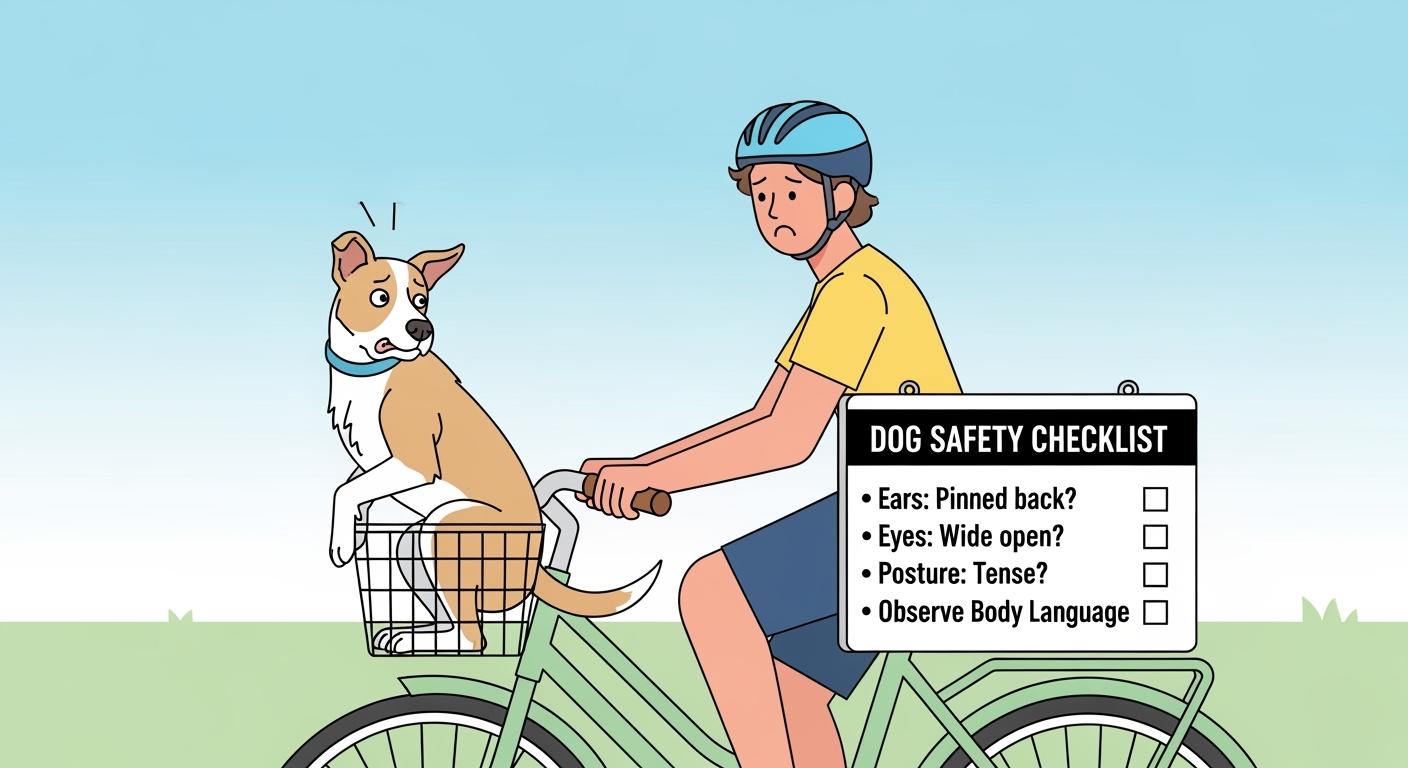

Complaint Handling for Low Visibility

You need a simple way to handle complaints about low visibility. Sometimes, customers say their reflective dog collar did not work well at night. Collect all details about what happened, like the time, place, and lighting. Ask for pictures of the collar and where it was used. Look at the collar’s condition and check if it matches your test results. If the collar is damaged or worn out, write this down. Use a checklist to help you respond:

Write down the complaint and contact info.

Ask for photos and a description of the problem.

Compare the collar’s condition to your test standards.

Decide if you should replace the collar or look into it more.

Tip: Quick replies help build trust. Customers see you care about safety and quality.

Traceability Query Path

You must be able to trace every collar back to its batch. Start with the lot or roll ID from your traceability records. Find the date you got it, the finished-goods code, and when it was made. Check carton or pallet IDs to find the batch. Use this info to see if other collars from that batch have the same problem. If you notice a pattern, test more collars from that batch to check for issues. You can use a table to keep track of your trace steps:

Step | Action |

|---|---|

Locate Lot/Roll ID | Find in traceability records |

Check Dates | Look at receiving and production dates |

Identify Batch | Use finished-goods code and carton IDs |

Review History | Check for past complaints or problems |

Initiate Testing | Test samples from the same batch |

Note: Good traceability helps you act fast and stop bigger problems.

Escalation and Documentation

You must act quickly if you get a reportable incident. In the US, you need to check and decide within 24 hours, following CPSA Section 15. Write down every step, including your investigation, test results, and what you did. Keep all records in your incident log. If you find a safety risk, tell your compliance team right away. Update your change-control log if you change any materials or steps. Use your testing plan to retest the affected batch and make sure it works. Share what you find with your team and keep buyers updated.

Call to Action: Ask Stridepaw for verification pack templates to help your post-market monitoring. Stridepaw can help you set up complaint handling, traceability, and escalation systems that follow US and EU rules.

A full reflective dog collars documentation kit keeps your brand safe. It helps you follow safety rules. Pets stay easy to see at night. Use checklists and templates to check supplier records. This helps you get ready for audits. Ask for all the needed documents. Look at them to make sure they are correct. Add these checks when you buy collars.

Reach out to Stridepaw for templates and help with compliance.

FAQ

What is a verification pack for reflective dog collars?

A verification pack is a group of papers from your supplier. It has test reports, traceability records, and label files. You use these papers to check if the collars follow safety and rule standards before buying or selling.

How often should I update my documentation?

Update your paperwork every time you change materials, suppliers, or steps. Regular updates keep your records correct and help you get ready for audits.

Why do I need to keep traceability records?

Traceability records let you track each batch of collars. If there is a problem, you can find and fix it fast. These records also show you follow safety rules and protect your business.

What does RA mean in testing?

RA means coefficient of retroreflection. It shows how much light the collar sends back to a light source. High RA numbers make collars easier to see at night.

What label claims are allowed for reflective dog collars?

You can say the collar helps people see pets better in low light when lit up. Do not promise safety or accident prevention. Always use approved words on your labels to follow the rules.

How do I handle a pet owner’s complaint about low visibility?

Collect details about the complaint and check the collar’s condition. Look at your test records. If needed, replace the collar or check more. Fast replies show you care about safety.

How long must I keep technical documentation?

Keep technical papers for 10 years and traceability records for 6 years after selling the product. This helps you follow EU rules and answer safety questions.

What should I do if I change a material or supplier?

Write down the change in your log, check the risk, and test the collar again. Only say yes to the change if the collar still meets all safety and performance rules.