Imagine a dog sling carrier that breaks because you did not set clear load limits or use good stitching. Your dog could fall out if the weakest part of the sling breaks. You must think about safety and strength, especially with hiking dog harness or dog lift harness features. Breaking strength and safety rules help lower risk in the pet travel market. When you pick materials for easy-clean carriers, comfort and a good harness fit are important. Eco-friendly materials and smart features keep your dog safe and make the carrier work better.

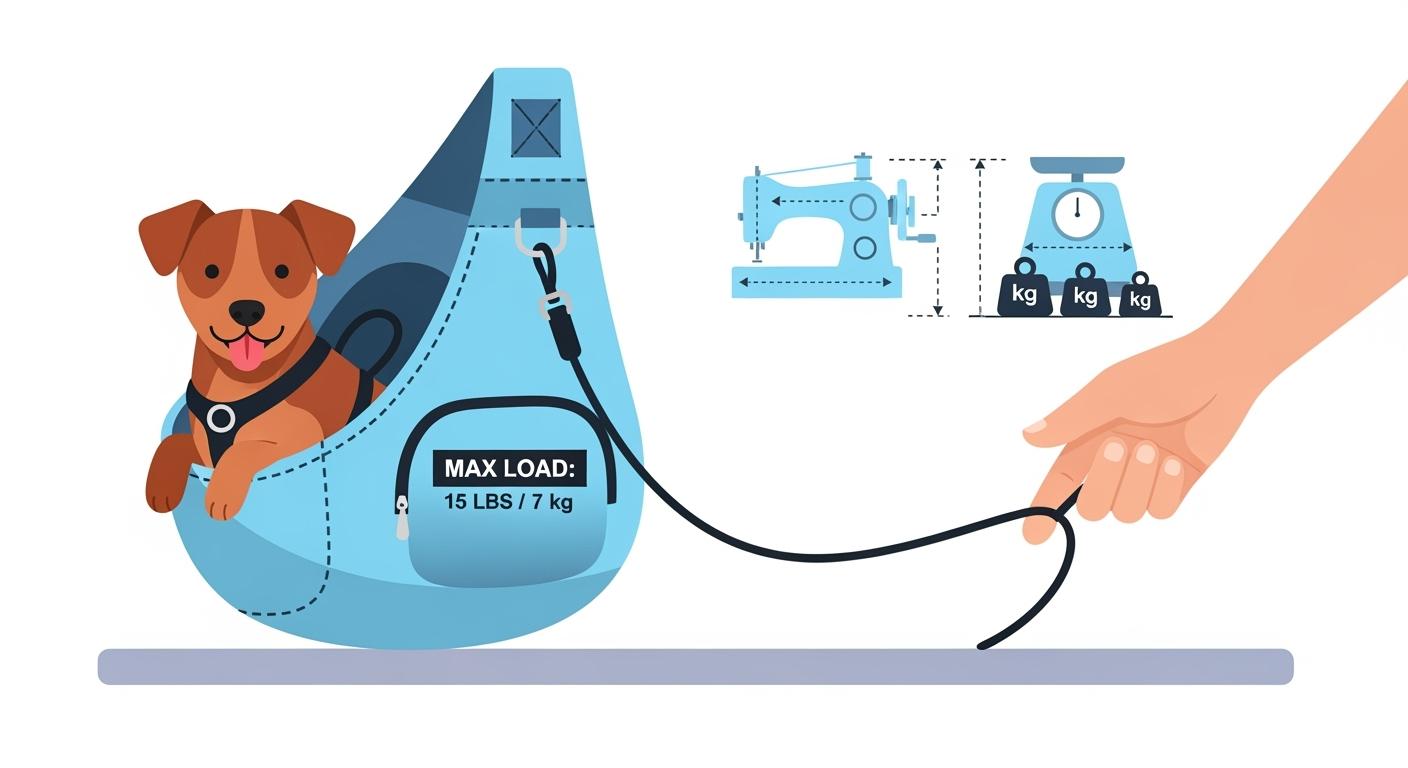

Load limits, stitching, and tether strength show how well the dog sling carrier works.

Every part, from where you attach things to the carrier’s shape, must keep your dog safe.

Good materials and comfort features help your dog travel safely.

Key Takeaways

Make sure you set clear load limits for dog sling carriers. This helps keep dogs safe and stops accidents from happening.

Use strong materials and add extra stitching to make the carrier last longer. This gives better support for your dog.

Test each carrier for load limits and durability. This helps keep good quality and makes people trust your brand.

Make sure the tether connects to the harness, not the collar. This lowers the chance of choking.

Add comfort features like wide straps and soft liners. These make it nicer for both the dog and the person using it.

Independent crashworthiness studies from groups such as the Center for Pet Safety (CPS) show that not every carrier marketed as “crash tested” performs well in dynamic tests. Only a few models, including the Sleepypod Mobile Pet Bed with PPRS Handilock and the PetEgo Jet Set Forma Frame Carrier with ISOFIX-Latch Connection, have been named top performers in CPS research. These programs use sled tests based on FMVSS 213 child-restraint methods and give you neutral data you can reference when briefing OEM/ODM partners.

Dog Sling Carrier Safety and Quality Specs

Safety Risks and Brand Reputation

You need to think about safety for every dog sling carrier. If a carrier breaks, people will not trust your brand. Customers want good products and help when needed. If a harness does not fit or breaks, people may write bad reviews. You could lose trust from buyers. Carriers should hold the dog well and stop falls. The table below shows how safety and test results change brand reputation:

| Brand Example | Safety Claim | Independent Finding | Reputation Impact |

|---|---|---|---|

| Sleepypod Mobile Pet Bed | Crash tested, CPS Certified | Met Center for Pet Safety crash-test performance criteria and earned top ratings under CPS carrier standards. | Very positive – clear third-party data supports marketing claims. |

| PetEgo Jet Set Forma Frame Carrier (with ISOFIX-Latch) | Crash-tested carrier | Named a Top Performer in CPS crashworthiness research when used with the ISOFIX-Latch connection system. | Positive – when sold and installed in the configuration that was tested. |

| Other brands claiming “crash tested” | Crash-tested marketing claim | Either failed CPS performance requirements or provide no independent crash-test data. | Negative or uncertain – customers and buyers may question safety claims. |

If a harness or sling fails, your brand looks bad. You need clear rules for safety, quality, and harness support. This helps you avoid recalls and keeps your dog harness advice strong.

What Independent Standards Mean for Sling Carrier Briefs

Crash-test programs such as CPS do not currently publish a sling-specific standard, but their carrier and crate work gives you a useful reference. CPS protocols build on FMVSS 213 child-restraint methods and require that the test dog dummy stays fully contained and the carrier stays connected during and after the test.

- Use CPS-style sled tests as a model when you write your own dynamic test plan for sling carriers.

- Ask third-party labs to reference FMVSS 213 methods when they design load and excursion tests for your carrier-and-sling concepts.

- Watch ASTM’s new F15.05 pet-product safety work so you can align future briefs with emerging industry standards, even before they become widely adopted.

This turns external standards and research into concrete requirements in your tech packs instead of vague “crash tested” claims.

Common Failure Points

It is important to know where dog sling carriers break most. Reviews and recalls show these problems:

Dogs can suffocate if there is not enough air or the fit is too tight.

Dogs can fall if the harness or tether does not hold them.

There are not enough warnings or instructions for safe use.

Stitching is weak or materials break when carrying weight.

Harnesses do not fit well and dogs can slip out.

Tether points do not hold the dog or harness well.

Every carrier should hold the dog and harness safely. Use strong materials and good stitching. Make sure the harness fits and the tether connects to the harness, not the collar. This lowers risk and keeps your brand promise.

Specs Checklist for OEM/ODM Projects

You need a simple checklist before talking to your factory. This helps you set rules for safety, quality, harness fit, and support. Use this checklist for your OEM/ODM dog sling carrier projects:

Tip: Always put this checklist in your tech pack or factory notes. It helps you share safety and quality needs.

Dog Sling Carrier Specs Checklist

Weight Limit: Say the highest dog weight allowed (usually 10–25 lbs for small breeds).

Main Fabric: Pick strong, water-resistant material (like 600D PU-coated polyester).

Lining: Choose light, easy-clean fabric that wicks moisture (like 210T nylon taffeta).

Webbing: Use tough polypropylene webbing for harness support and load points.

Thread: Pick strong bonded nylon thread so seams do not break.

Hardware: Ask for smooth zippers and good D-rings for harness attachment.

Stitching: Set a minimum stitch amount and pattern for seams that carry weight.

Tether: Make the tether attach to the harness, not the collar, and set strength rules.

Fit: Make sure straps adjust for harness fit and dog comfort.

Internal Compartments: Say how big pockets are, where dividers go, and zipper lengths.

Tolerances: Set allowed changes (like ±3 mm) for material stretch and machine settings.

Closure Systems: Say what kind and where (magnetic snaps, roll-top buckles, drawstrings).

Adjustability: Include strap length choices and buckles for harness fit and load balance.

Testing: Ask for water resistance, abrasion resistance, tensile strength, flame retardance, and smellproof tests.

- Openings: Keep gaps small enough that noses and paws cannot slip through (for example, around 20–25 mm for small dogs), and state your chosen limit clearly in the spec.

Handles: Ask for handles on both sides for safe lifting and harness support.

Live Animal Label: Put the label where it can be seen but do not block mesh air panels.

Set rules for every part that holds the dog and harness. This checklist helps you stop common problems and make good carriers. You protect your brand by focusing on safety, harness fit, and strength. Always use clear rules and test each carrier to lower risk.

Load Limits and Durability in Dog Sling Carriers

Recommended Weight Range

You need to set a clear weight range for every dog sling carrier project. Most OEM/ODM dog sling carriers support dogs between 10 and 25 lbs. This range fits small breeds and young dogs. Leading manufacturers show these limits in their specs:

Manufacturer | Weight Range |

|---|---|

Ownpets | 10~25 lbs |

Rainbow Woven | Up to 17 lbs |

You should always check the breed size and the weight of the dog before choosing a carrier. The table below helps you match the right carrier to the right dog:

Breed Size | Weight Limit | Example Breeds |

|---|---|---|

Small Breeds | 5lb – 18lb | Chihuahuas, Yorkies, Pomeranians |

Most brands provide size charts to help you select the correct carrier. Make sure the carrier supports your dog’s weight comfortably. The sling must give enough space for your dog to sit or lie down without feeling cramped.

Structural Design for Durability

Durability starts with the right construction. You must use strong fabrics and robust materials at every load-bearing point. The construction should include reinforced seams, double stitching, and extra support at stress points. Strong fabrics like 600D polyester or heavy-duty canvas help the carrier last longer and resist tearing.

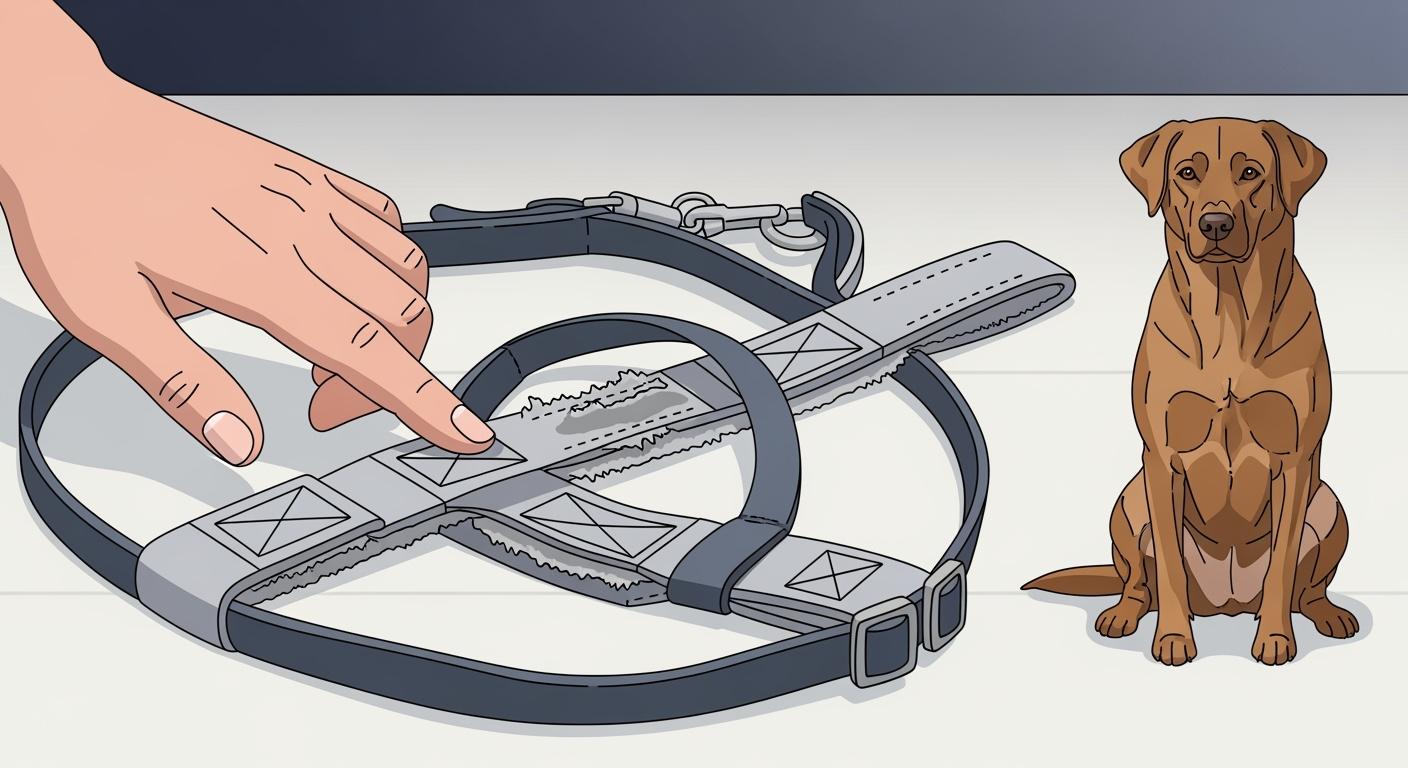

You need to check the construction of the sling. Look for wide straps, padded panels, and secure closures. The load path should direct the dog’s weight through the strongest parts of the carrier. All attachment points, such as D-rings and buckles, must use strong fabrics and high-quality materials. This design helps reduce the risk of failure during use.

Tip: Always ask your factory to show you the inside of the carrier. You want to see how the construction supports the dog and spreads the load.

Load Testing and Safety Margins

You must test every dog sling carrier for load limits and durability. Load testing checks if the construction and materials can handle the dog’s weight. You should use both static and dynamic tests. Static tests hold a set weight for a period of time. Dynamic tests add movement, simulating walking or sudden pulls.

Set a safety margin above the maximum dog weight. For example, if the carrier is rated for 20 lbs, test it with at least 30 lbs. This margin helps reduce the risk of failure from sudden movements or material fatigue. Always test the construction at all load-bearing points, including straps, seams, and tether attachments.

You should also check the durability of the strong fabrics after repeated use. Look for signs of wear, such as fraying, stretching, or seam separation. The construction must keep its shape and strength after many cycles of use.

Three-Level Load-Test Pyramid for OEM/ODM Projects

To keep testing practical but still serious, use a simple three-level load-test pyramid for every new sling carrier brief:

- Bench testing on early samples – Run static and dynamic load tests at 1.5x the rated dog weight on size-run samples before you approve materials and construction.

- Pre-production pilot testing – Repeat key load tests on pilot lots from the mass-production line to make sure stitching patterns, thread types, and webbing match the approved spec.

- In-use field checks – Have staff or partner testers use weighted dummies or suitable dogs on short walks, then record any signs of strap slip, seam movement, or user discomfort.

This pyramid turns “we tested it” into a repeatable process you can show to buyers and auditors.

Load Limit Checklist

Use this checklist to brief your factory and QC team on load limits and durability:

State the maximum dog weight (e.g., 10–25 lbs) for the carrier.

Specify strong fabrics for the main body and straps.

Require reinforced construction at all load-bearing points.

Set minimum seam strength and stitch density.

Ask for static and dynamic load testing at 1.5x the rated weight.

Check that all materials meet consumer textile safety rules.

Inspect the construction for even stitching and secure closures.

Review the load path to ensure the dog’s weight spreads evenly.

Test the carrier with a live dog or weighted dummy for fit and comfort.

Document all test results and keep them in your QC records.

Note: Always include this checklist in your tech pack or factory brief. Clear specs and testing steps help you reduce risk and improve durability.

By focusing on the right weight range, strong fabrics, and robust construction, you help ensure the dog sling carrier is designed to support the dog safely. Regular load testing and clear communication with your factory help you deliver a product that meets your brand’s standards for durability and safety.

Stitching Quality and Comfort

Stitching Types and Patterns

Stitching is very important in dog sling carriers. It keeps the carrier together and stops it from breaking. Reinforced stitching is needed at places that hold weight. Strong seams like double or box stitches help carry the dog’s weight. Zigzag and cross-stitch patterns make the carrier stronger. These patterns spread out stress and stop seams from splitting. Always tell your factory what stitching you want for safety and comfort.

Stitch Density and Thread Quality

Stitch density matters for safety and comfort. You need enough stitches in each inch to keep seams strong. If there are not enough stitches, seams can break and wear out fast. More stitches help the carrier last longer and keep the dog safe. Use thick polyester thread for all seams. Polyester thread does not break easily and stands up to washing and sunlight. It helps the carrier hold weight and movement. Do not use cotton thread because it wears out quickly. Always check that the thread matches the carrier’s materials.

Polyester thread lasts a long time.

Thick polyester thread is best for pet carriers.

Strong seams keep the dog safe and comfortable.

Comfort Features in Sling Carriers

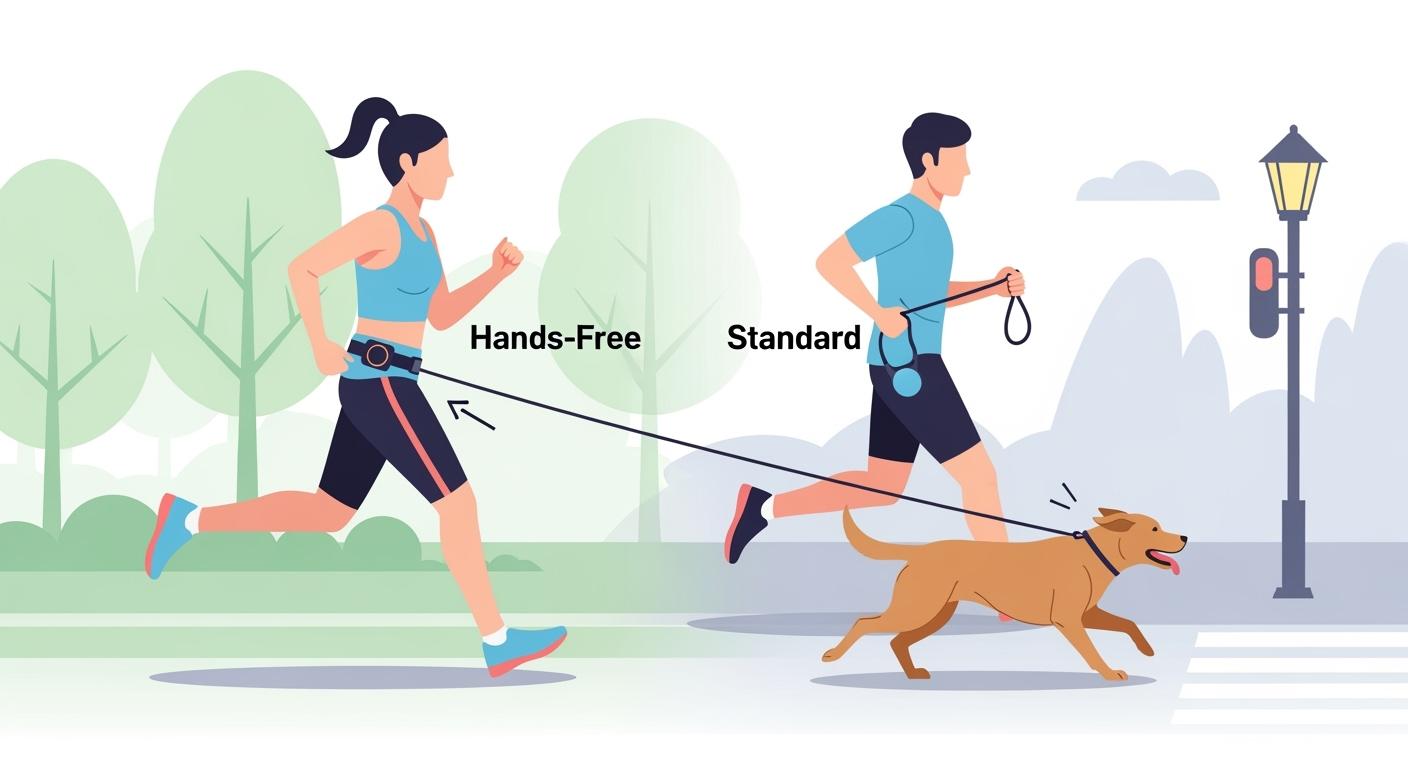

Comfort is important for both the dog and the person. Look for features that lower pressure and make carrying easier. Wide straps spread out the weight and help your shoulders. Soft materials keep the dog happy and dry. Removable liners make cleaning simple and add comfort. Padded and adjustable straps help you get the right fit. Machine washable carriers are easy to clean. Safety straps and crossbody designs keep the dog safe and let you use your hands.

Feature | Description |

|---|---|

Designed for small breeds | Made for small dogs and cats. |

Soft and comfortable | |

Wide strap | Spreads weight for user comfort. |

Machine washable | Easy to clean and keeps things hygienic. |

Moisture and stain resistant | Stops spills and accidents from ruining the carrier. |

Safety strap | Keeps the dog in place. |

Crossbody design | Lets you carry the dog hands-free. |

Swivel clip | Makes it easier to secure the dog. |

Simple Comfort Walk Test You Can Repeat

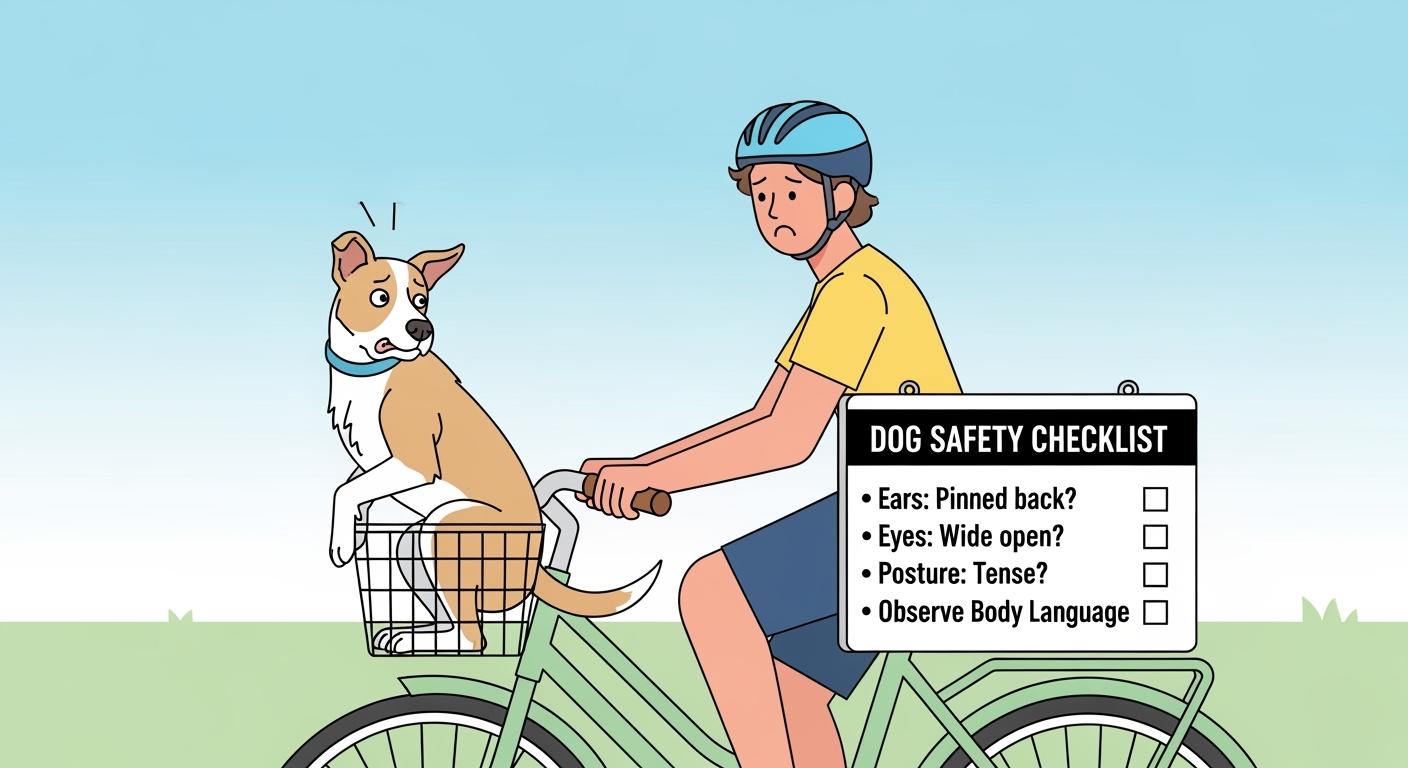

Lab tests will not tell you everything about comfort. Add a short “comfort walk test” to your QC playbook:

- Load the sling to its typical dog weight using a dummy or sandbags and adjust the straps as a customer would.

- Ask two or three staff members with different body sizes to walk for 15–20 minutes, then score shoulder pressure, heat build-up, and how stable the dog feels on a 1–5 scale.

- Record comments such as where the straps dig in, how the dog’s body sits in the sling, and whether hands-free use really feels safe.

Summarize these notes in your sample review sheet so designers and factories can see real feedback, not just lab numbers.

Stitching and Comfort Checklist

Use a checklist to check stitching and comfort in every dog sling carrier.

Ask for reinforced stitching at weight points.

Make sure seams are strong with lots of stitches.

Use thick polyester thread for all seams.

Pick soft and tough materials for comfort.

Add removable liners for easy cleaning and comfort.

Measure the dog and user for a good fit.

Check that the sling supports the dog’s body well.

Avoid designs that are too tight or block air.

Make sure straps are padded and adjustable.

Confirm safety and comfort features like safety straps and wide straps.

Tip: Always put this checklist in your tech pack or factory notes. Clear rules help you keep every carrier safe and comfortable.

Tether Strength and Safety

Tether Materials and Construction

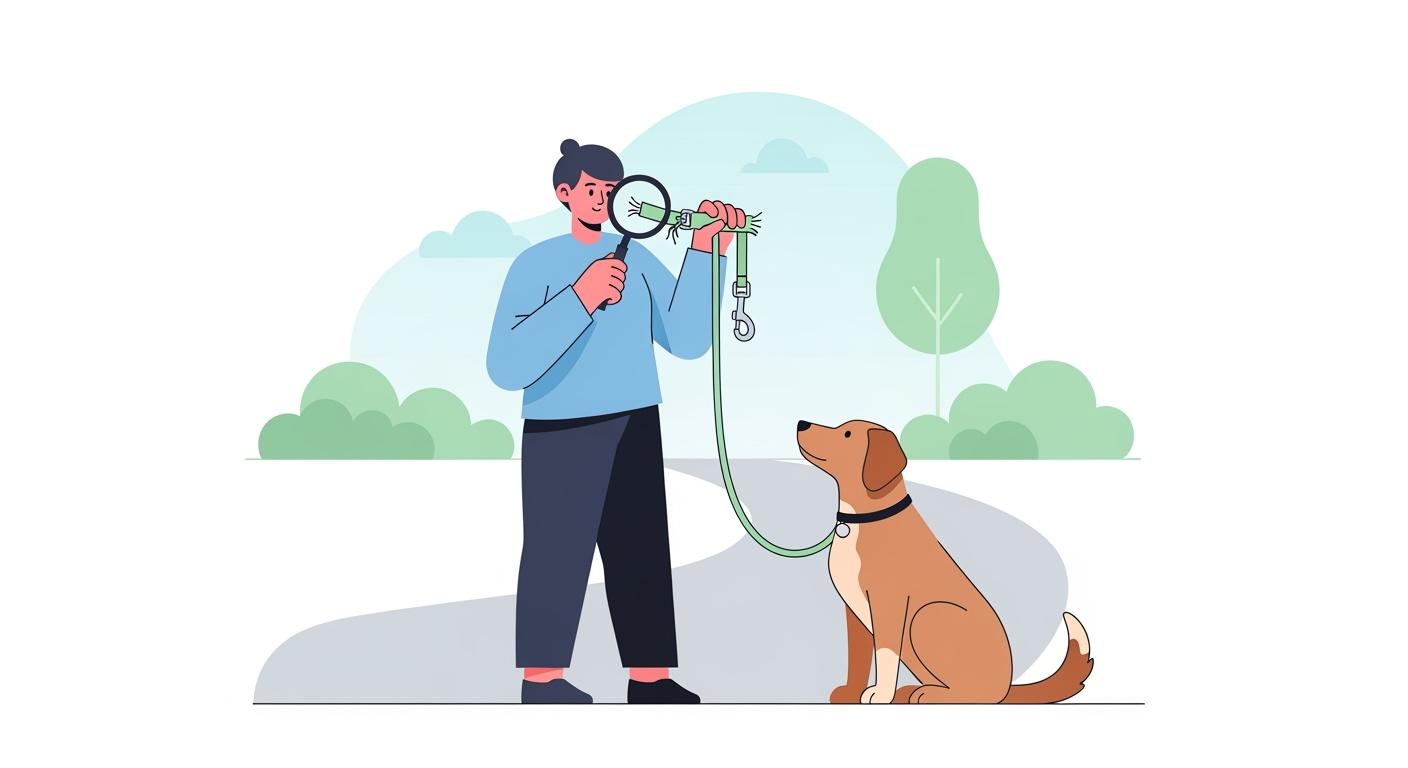

You must focus on the strength of the tether when designing a dog sling carrier. The tether keeps the dog inside the carrier and helps prevent accidental falls. You should choose materials that have high tensile strength, such as thick nylon webbing or reinforced polyester. These materials resist fraying and stretching. The construction of the tether should include secure closures, like heavy-duty clips or carabiners, that attach to the dog’s harness. You want the tether to stay strong even if the dog pulls or moves suddenly. Good tether construction helps keep the dog secure in public places, such as airports or veterinary offices. This design helps reduce the risk of escape and improves overall safety.

Attachment Points and Safety

You need to check the strength of the attachment points for the tether. These points must connect to reinforced areas of the dog sling carrier. You should avoid attaching the tether to weak seams or thin fabric. Use secure closures, such as double-stitched D-rings or sewn-in loops, to hold the tether in place. The attachment should connect to the dog’s harness, not the collar, to lower the risk of choking or injury. You must inspect these points for wear and test them for strength before each use. Strong attachment points help keep the dog safe during travel.

Tether Testing and Rating

You should test the tether for both static and dynamic loads. Static tests check if the tether can hold a set weight for a long time. Dynamic tests simulate the dog’s movement, such as jumping or pulling. You want the tether and secure closures to hold at least 1.5 times the maximum dog weight. You should also check the tether after repeated use to see if it shows signs of wear or loss of strength. Always document your test results and include them in your quality control process. This approach helps you design a dog sling carrier that meets your safety goals.

Tether Safety Checklist

Use this checklist to brief your factory and QC team on tether strength and secure closures:

Specify high-strength materials for the tether (nylon webbing or reinforced polyester).

Require secure closures, such as heavy-duty clips or carabiners.

Attach the tether to reinforced points with double stitching.

Connect the tether to the dog’s harness, not the collar.

Test the tether and secure closures for static and dynamic loads at 1.5x the rated dog weight.

Inspect the tether and attachment points for wear before each shipment.

Document all test results and keep them in your QC records.

Tip: Always include this checklist in your tech pack or factory brief. Clear specs and regular testing help you reduce risk and improve the strength of your dog sling carrier.

OEM/ODM Partner Briefing for Dog Sling Carriers

Key Questions for Suppliers

When you start a dog sling carrier project, you should ask your suppliers simple questions. This helps you check if the carrier is strong and fits well. You want to make sure the carrier matches your brand and keeps dogs safe. Use these questions when you meet your supplier:

What steps do you take to check harness stitching and seams?

How do you test if small dogs fit and get support?

What materials do you use for the body, harness, and tether?

Can you show how the harness connects and holds the dog?

What features make the carrier comfortable for dogs and people?

How do you test the tether and where it attaches?

What is your way to check each batch for quality?

How do you fix problems with harness fit or quality?

Tip: Always ask for samples that show harness fit, support, and quality before you say yes to production.

Certifications and Testing Protocols

You need to set easy testing rules for every dog sling carrier. Most places do not have strict rules for pet carriers, but you should make your own. These rules help you check if the carrier is strong and fits well. Your rules should cover:

Testing the harness and carrier with weight that does not move and weight that moves

Checking if small and young dogs fit well

Looking at all places that hold weight and where the harness connects

Making sure all materials are safe for dogs

Checking stitching, harness fit, and comfort features for quality

For chemical and textile safety, look at the general consumer-product frameworks in your target markets, such as REACH in the EU or CPSIA and state-level rules in the U.S. Even though there is no dog-sling-specific law today, using these frameworks for heavy metals, azo dyes, and phthalate limits shows buyers that your carrier program follows the same discipline as children’s products and mainstream soft goods.

Your rules help lower risk and show you care about quality. You should keep records of all your tests and checks.

Sample Factory Brief Checklist

A simple checklist helps you tell the factory what you need. Use this checklist for your dog sling carrier project:

Say the weight range for small dogs

List all main materials, harness webbing, and tether details

Ask for strong stitching at all places that hold weight and harness points

Say how the harness should fit and support the dog

Add comfort features and ways to adjust the fit

Set steps to check harness, fit, and support for quality

Ask for test results for weight that does not move and weight that moves

Ask for checks at all harness connection points

Ask for papers that show all quality checks

Note: Add this checklist to your tech pack or factory notes. Clear steps help you get good quality, harness fit, and support for every dog sling carrier.

You improve safety and comfort by setting clear specs for every dog sling carrier project. Use strong materials and test all load points. Focus on comfort for both the dog and the user. Add features that support comfort, like wide straps and soft liners. Check comfort in every sample. Use checklists to guide your factory. Document comfort and safety steps in your tech pack. Make comfort a key part of your QC process. Always review comfort and safety before each shipment.

FAQ

What weight range should you specify for dog sling carriers?

Pick a weight range that matches small or young dogs in your target market. Many soft sling carriers are designed for dogs in the 10–25 lb range, but you should confirm the limit with your factory and test plan. Clear, tested limits help make sure the carrier holds the right weight and support your safety message.

How do you check if stitching meets safety requirements?

Ask for strong stitching at places that hold weight. Tell your factory to share details about stitch amount and thread type. Look at samples to see if seams are even and tight. Write down what you find in your QC records.

Why must the tether attach to the harness, not the collar?

The tether should connect to the harness, not the collar. This lowers the chance of choking or hurting the dog. The harness spreads force over the dog’s body. Collars can hurt the dog if it pulls or falls.

What testing should you require for load limits?

Ask for tests that use both still and moving weight. Test with 1.5 times the weight the carrier is made for. Check straps, seams, and tether spots. Write down results for every batch you make.

How do you ensure compliance with safety and chemical requirements?

Say that all materials must meet safety and chemical rules. Ask suppliers for papers that show this. Check materials during your quality control steps.