Imagine you get a box of collars for little dogs. You find weak buckles and sizes that do not match. This mistake can cause safety problems and cost you money to return. You should ask important questions before you buy: Is the hardware the right size and has it been tested? Do suppliers give clear neck sizes and collar width? How do they check for strength and rust resistance? Good answers help you keep your brand safe and give small dogs safe collars.

Key Takeaways

Always ask suppliers if they test the hardware. Make sure buckles and rings are strong for daily use.

Check that collar sizes fit neck measurements. Use the two-finger rule for a comfy fit.

Ask for proof that hardware resists rust. Request test reports to show it can handle moisture.

Talk clearly about what the product can do. Use safe words to set real expectations for collar use.

Teach your team about sizing and safety. Give them info to help customers pick the right collars.

Risks of Lightweight Hardware

Lightweight hardware can seem like the perfect choice for collars for little dogs. It reduces bulk and helps small breeds feel more comfortable. However, lightweight does not always mean safer or stronger. You need to know the risks before you approve a supplier or product.

Common Failure Issues

Many buyers see returns and complaints because lightweight hardware can break or deform. Small buckles and thin rings may not handle daily use if the materials or design are not right. If a collar fails, it can put both the dog and your brand at risk. Always ask suppliers how they test for breakage and what steps they take to prevent weak points.

Weight Limits and Slippage

Lightweight hardware often has lower weight limits. If the hardware is too small or not matched to the collar width, it can slip or twist. This can cause the collar to loosen or even come off during a walk. You should check that the hardware fits the webbing and matches the neck size range. Ask for clear information about the maximum safe use, such as “for everyday walking” and not for tie-out or heavy pulling.

Corrosion Concerns

Metal parts on collars for little dogs face extra risk from moisture. Corrosion can weaken hardware and shorten the collar’s life. To help prevent this, you can:

Hand wash collars with mild soap

Rinse well and air dry flat

Wipe metal parts dry after wet walks

These steps help keep hardware strong and safe. Always ask suppliers if they run corrosion tests and what coatings or materials they use to protect against rust.

Tip: Request test reports for both strength and corrosion resistance before you place a large order.

Key Terms for Collars for Little Dogs

Understanding the right terms helps you source safe and reliable collars for little dogs. Clear definitions make it easier to compare products and communicate with suppliers.

Lightweight Hardware Defined

Lightweight hardware means smaller, less bulky parts designed for small breeds. You get less weight around the neck, which helps reduce collar rotation and discomfort. Lightweight does not mean stronger. You should always ask for proof that the hardware matches the needs of collars for little dogs and passes strength and safety checks.

Buckle and D-Ring Basics

The buckle is the closure that keeps the collar secure. For collars for little dogs, you want a buckle that is easy to open and close but does not pop open by accident. The D-ring is the metal loop where you attach a leash or ID tag. Make sure the D-ring is smooth and sized to fit the collar width. A D-ring that is too thin can bend or rust faster.

Webbing and Hardware Sizing

You need to know three main sizing terms:

Webbing width: The width of the collar strap itself.

Hardware inner width: The space inside the buckle or ring where the webbing passes through.

Ring wire thickness: How thick the metal is on the D-ring or O-ring.

Tip: Always match the hardware inner width to the webbing width. This helps prevent twisting and slippage.

Coating vs Solid Metal

Choosing the right metal for hardware affects both strength and how long the collar lasts. Here is a quick guide:

Type | Material Description | Performance Characteristics |

|---|---|---|

Solid Brass | Brass all the way through—no coating. | Naturally corrosion-resistant, strong, and ideal for long-term durability. |

Brass-Plated | Steel or zinc beneath a thin brass coating. | Lightweight, affordable, may wear over time with heavy use. |

Stainless Steel | Heavy-duty, weather-proof material. | Extremely strong, corrosion-resistant, ideal for high-stress applications. |

You should ask suppliers which type they use and request test results for corrosion and strength.

Messaging for Lightweight Collars

What Lightweight Means

You want collars for little dogs to feel safe and comfy. Lightweight hardware means the collar is not heavy or bulky. It uses small buckles and rings that fit the collar size. This does not make the collar stronger or last longer. It just means the parts are the right size for small dogs. This helps stop the collar from turning around the neck. Always make sure lightweight hardware passes safety and strength tests before you choose it.

Setting Realistic Expectations

You must tell your customers and team what to expect. Lightweight collars are best for daily walks and short trips. They also work well for trying on in stores. These collars are not made for tie-out, strong pulling, or chewing. Do not say the collar can do more than it really can. Use words that show what the collar is for and what it cannot do. This helps stop returns and makes buyers trust you.

Note: Always use “lightweight” with “tested and checked by QC” in your product info.

Safe Messaging Templates

You can use these ideas to write safe and honest product info:

“Small buckle made to keep collars light for little dogs.”

“Hardware fits collar width to help stop twisting.”

“Closure tested and sizing checked during QC.”

“Clear width and neck sizes help stop wrong orders.”

“Best for daily walks, short trips, travel, and store try-on.”

Do not use words like “escape-proof” or “guaranteed.” Always tell buyers to check the fit and look at the hardware before using. If a dog has neck or breathing problems, tell buyers to ask a vet.

Fit and Sizing Rules

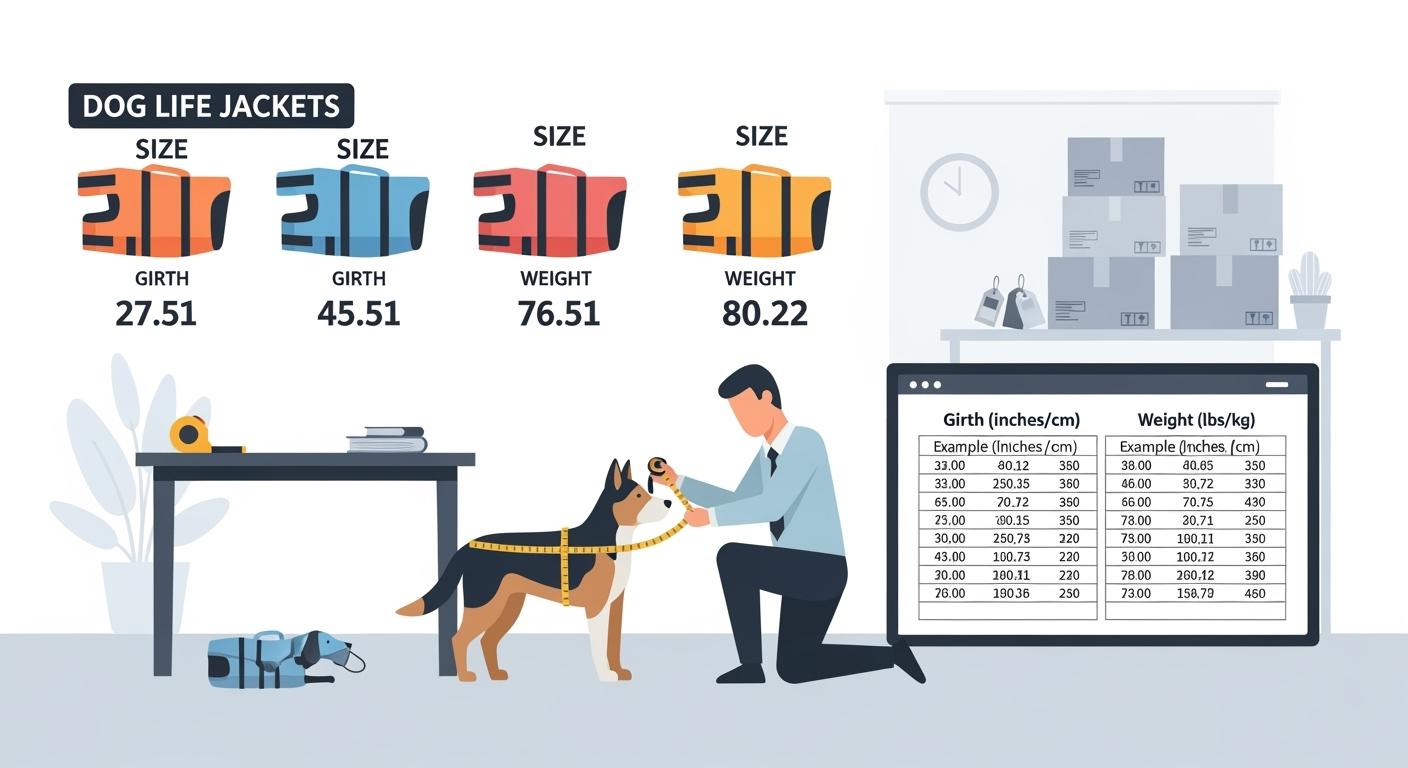

Measuring Neck Circumference

Getting the right fit starts with measuring neck circumference. You want to measure at the widest part of the dog’s neck, where the collar will sit. Use a soft tape measure. Hold the tape snug but not tight. This helps you get an accurate reading. Always use the two-finger rule: after you put the collar on, you should be able to slide two fingers between the collar and the dog’s neck. This ensures the collar is secure but not too tight.

Measure at the widest part of the neck.

Keep the tape snug, not tight.

Use the two-finger rule for comfort and safety.

Tip: Record the neck measurement in centimeters and inches. This helps you compare with supplier size charts and reduces confusion.

Collar Width and Hardware Fit

Collar width matters for both comfort and safety. For collars for little dogs, you want a strap that is not too wide or too narrow. Always publish the collar width as a clear measurement. Do not rely on size names like “small” or “XS” alone. The hardware inner width should match the webbing width. If the hardware is too wide, the collar can twist or slip. If it is too narrow, the strap may bunch up or not move smoothly.

Term | What It Means | Why It Matters |

|---|---|---|

Webbing width | Width of the collar strap | Affects comfort and fit |

Hardware inner width | Opening where the strap passes through | Prevents twisting and slippage |

Ring wire thickness | Thickness of the D-ring or O-ring | Impacts strength and corrosion risk |

Always check that the hardware fits the strap. This reduces the risk of failure and keeps the collar working as intended.

Reducing Wrong Size Returns

Clear sizing information helps you reduce returns and exchanges. Always show neck size ranges and collar width in your product data. Use simple language and avoid only using size codes. Give buyers a step-by-step guide for measuring their dog’s neck. Remind them to use the two-finger rule for checking fit. When you communicate size clearly, you help buyers choose the right product the first time.

Publish neck size range and collar width for every SKU.

Use a table or chart to show size options.

Add a measuring guide to your product page or packaging.

Remind buyers to check fit before use.

Note: Consistent sizing rules and clear communication lower the risk of wrong-size returns and improve customer trust.

Claim Governance for Collars for Little Dogs

Safe vs Risky Claims

You must be careful with claims about collars for little dogs. Safe claims use simple words and match what your product can show. Risky claims promise things you cannot prove or go past your test results. In the US and EU, you need real proof for every claim you make. If you say your collars do more than they can, you might get returns, legal trouble, or hurt your brand.

Scope and Limits Language

Always tell buyers what your collars can and cannot do. Use words like “for everyday walking” or “not for tie-out or towing.” This helps buyers know how to use the collar. You should also say that how well the collar works depends on fit, use, and checking it often. These limits help protect your business and help you follow rules as EU laws change and US rules focus on proof for claims.

Note: Using clear words about what collars can do helps stop confusion and helps you follow rules in the US and EU.

Claims to Avoid

Do not make big promises or say things about behavior. Never say “escape-proof,” “chew-proof,” or “guaranteed.” These words need proof that is very hard to get. Also, do not talk about medical benefits or new tech unless you have strong proof. The market changes quickly, so you must keep your claims honest and up to date.

Claim Governance Table

Here is a table to help you check and change claims for collars for little dogs. Use it when you talk to suppliers or write about your product.

Phrase or claim | Safe rewrite | Proof to request | Avoid because |

|---|---|---|---|

Escape-proof | Secure fit for everyday walking | Fit test results, closure function checks | Cannot guarantee all dogs will not escape |

Chew-proof | Not designed for chewing | Material test reports, usage instructions | Chewing can damage any collar |

Guaranteed not to break | Validated by strength and corrosion testing for daily use | Test reports, QC records | No collar is unbreakable |

Pull-proof | Right-sized hardware for small-breed comfort | Hardware sizing data, strength test results | Pulling force varies by dog and situation |

Medical benefit claims | Consult a veterinarian for dogs with sensitivities | N/A | Medical claims require clinical evidence |

For tie-out use | Not designed for tie-out or towing | Usage instructions, product labeling | Tie-out use needs special hardware and testing |

Use this table to help you write safe product info and talk to suppliers. Always ask for test reports and clear proof before you make any claim.

Test and QC for Small Dog Collars

Quality control protects your business and your customers. You need to check every shipment of collars for little dogs before you accept it. Good test and QC steps help you avoid weak hardware, poor stitching, and sizing mistakes.

Incoming Inspection Steps

Start with a clear inspection process. Use these steps when you receive a shipment:

Check for visual defects. Look for scratches, dents, or missing parts.

Test the closure function. Open and close each buckle to make sure it works smoothly.

Inspect for deformation. Squeeze rings and buckles to see if they bend too easily.

Examine stitching. Pull gently on seams to check for loose threads or skipped stitches.

Measure neck range and collar width. Use a tape measure to confirm the product matches your order.

Tip: Record all findings in your QC log. This helps you track supplier performance over time.

Corrosion and Strength Testing

Hardware must resist rust and stay strong during use. Ask your supplier for salt-spray test results. This test shows how well the metal stands up to moisture. Request tensile strength test reports for the webbing and hardware. These reports prove the collar can handle normal walking use. Always match test results to your product’s use case.

Sampling and AQL Plans

You should not check every collar in a large order. Use a sampling plan based on Acceptable Quality Limit (AQL). Define what counts as a critical, major, or minor defect. Sample enough units to catch problems but keep costs under control. Share your AQL plan with your supplier before production starts.

Note: AQL-based sampling helps you balance quality and efficiency.

Buyer Proof Checklist Table

You need clear proof from your supplier. Use this table to guide your checks and requests.

Component | What to request from supplier | How to verify at receiving |

|---|---|---|

Buckle & D-ring | Closure function test, salt-spray test | Open/close, check for rust or bends |

Webbing | Tensile strength test, width measurement | Measure width, pull test, inspect |

Stitching | Stitch count, seam integrity report | Visual check, pull seams gently |

Sizing | Neck range and width data | Measure with tape, compare to spec |

Packaging | Safety info, product ID, traceability | Check labels, match to order |

OEM (Original Equipment Manufacturer) means the supplier makes products to your brand’s design. ODM (Original Design Manufacturer) means the supplier offers their own designs, which you can brand. Always clarify which model you use, as it affects your QC steps and proof requests.

Channel Readiness for Retail and Ecommerce

Product Data and Copy Blocks

You need clear product data to do well in stores and online. Always use the same names, sizes, and measurements everywhere. Put neck size and collar width for each SKU on your website and packages. Add hardware material and care tips. Use safe messages like “right-sized hardware for small-breed comfort” and “checked by QC.” This helps buyers and workers know your collars for little dogs are safe and strong.

Tip: Make a product data table for each collar. Add neck range, width, hardware type, and care notes. This makes updates and exports simple.

Packaging and Safety Info

Packaging must show product details and safety info clearly. Print neck size, collar width, and hardware material on every package. Add a measuring guide and a two-finger fit reminder. Include a note like “for everyday walking, not for tie-out.” For EU export, make sure packaging matches listings and has traceability info like batch codes or product IDs.

Packaging Checklist | Why It Matters |

|---|---|

Neck size and width | Helps stop wrong-size returns |

Hardware material | Good for allergy questions |

Fit and use instructions | Makes safety and rules better |

Traceability info | Helps with recalls and audits |

Staff and FAQ Preparation

Train your staff to answer common questions. Teach them how to measure a dog’s neck and why collar width matters. Give them safe message ideas like “best for daily walks” and “not for tie-out.” Update your FAQ to cover fit, care, and claim limits. This helps your team give clear advice and stops confusion for buyers.

Note: Training staff and updating FAQs helps build trust and lowers returns.

When you buy collars for little dogs, ask simple questions. Make sure you ask about fit, hardware, and how the supplier tests. Always check if the claims are true and ask for proof. Use the guide and tables here to help your team buy and sell. Many stores get fewer complaints by showing clear pictures. These pictures show collar width and buckle details. This helps buyers pick the right size and trust your brand.

FAQ

How do you confirm hardware is right-sized for little dog collars?

Match the hardware inner width to the collar webbing. Ask your supplier for data and test reports. Make sure buckles and rings do not twist or slip. Check these things when you inspect new shipments.

What is the best way to communicate collar sizing to buyers?

Show neck size ranges and collar width for each SKU. Give buyers a simple measuring guide. Remind them to use the two-finger rule for fit. Clear sizing helps stop wrong-size returns and builds trust.

How do you verify claims about strength and corrosion resistance?

Ask suppliers for test reports. Look for salt-spray results for corrosion. Check tensile strength data for webbing and hardware. Read these reports before you approve any order. Only use claims you can prove with evidence.

What should you include on packaging for retail and export?

List neck size, collar width, and hardware material. Add fit instructions and a two-finger fit reminder. Include traceability info like batch codes. Good packaging helps with rules and stops confusion for staff and buyers.

How do you train staff to answer sizing and safety questions?

Give staff a simple measuring guide and safe message templates. Teach them to explain collar width, neck range, and hardware fit. Update FAQs often. Well-trained staff help buyers pick the right product and lower return rates.